Maintenance (continued), Carburetor adjustment, Loading trimmer line – Shindaiwa TRIMMER T242X User Manual

Page 20

20

Carburetor Adjustment

Engine Break-In

New engines must be operated a minimum duration of two tanks of fuel break-in before carburetor adjustments can be

made. During the break-in period your engine performance will increase and exhaust emissions will stabilize. Idle speed can

be adjusted as required.

High Altitude Operation

This engine has been factory adjusted to maintain satisfactory starting, emission, and durability performance up to

1,100 feet above sea level (ASL) (96.0 kPa). To maintain proper engine operation and emission compliance above

1,100 feet ASL the carburetor may need to be adjusted by an authorized Shindaiwa service dealer.

NOTE:

Every unit is run at the factory and the carburetor is set in compliance with emission regulations. Carburetor adjustments,

other than idle speed, must be performed by an authorized Shindaiwa dealer.

IMPORTANT!

If the engine is adjusted for operation above 1,100 feet ASL, the carburetor must be re-adjusted when operating the

engine below 1,100 feet ASL, otherwise severe

engine damage may result.

Maintenance (continued)

Adjusting Engine Idle

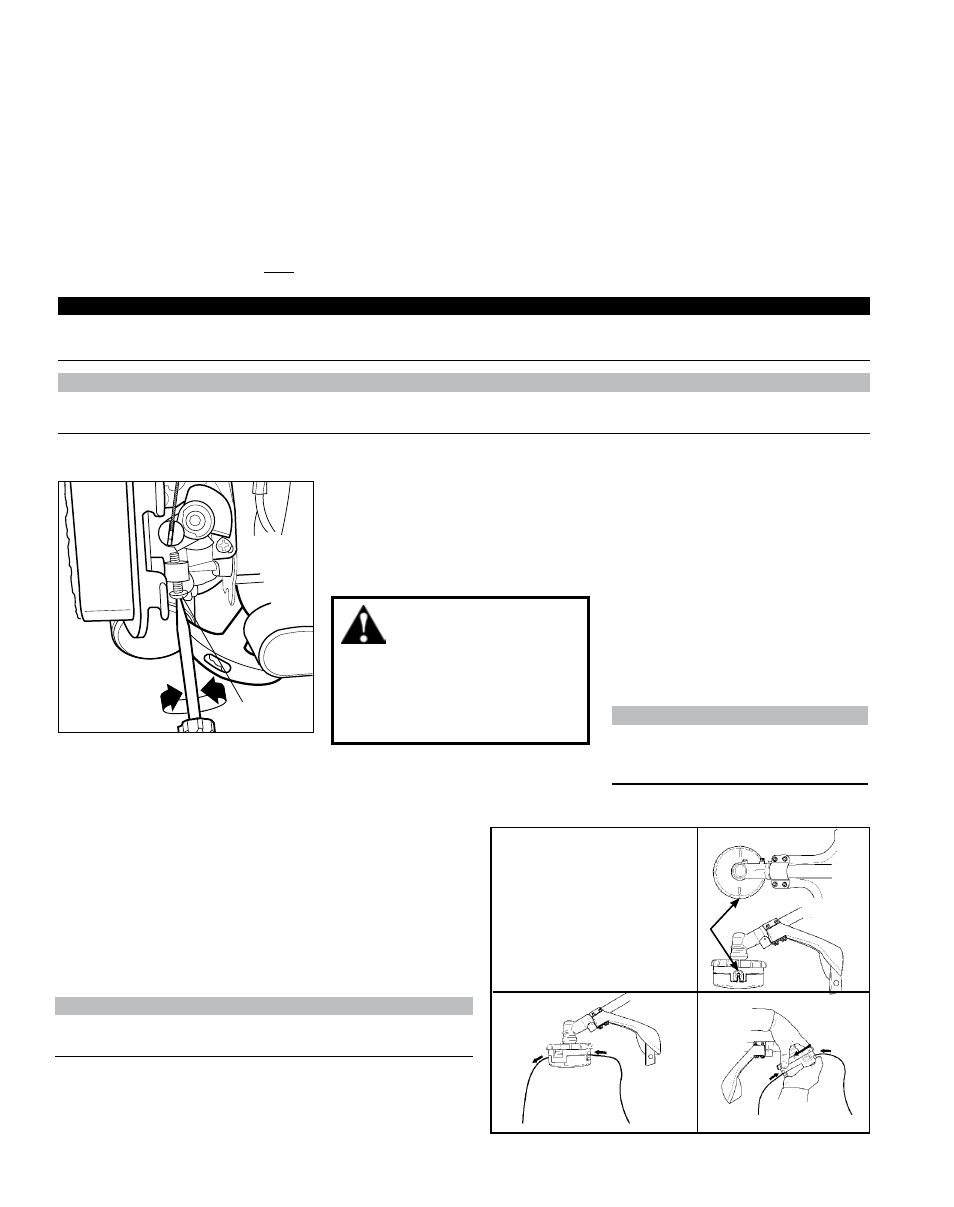

Figure 20

Idle Adjusting

Screw

The engine must return to idle speed

whenever the throttle trigger is

released. Idle speed is adjustable, and

must be set low enough to permit the

engine clutch to disengage the cutting

attachment.

WARNING!

The cutting attachment

must NEVER move at engine idle!

If the idle speed cannot be adjusted

by the procedure described here,

return the unit to your Shindaiwa

dealer for inspection.

Idle Speed Adjustment

1. Place the trimmer on the ground,

then start the engine, and then allow

it to idle 2-3 minutes until warm.

2. If the attachment moves when the

engine is at idle, reduce the idle

speed by turning the idle adjustment

screw counter-clockwise. See Figure

20.

3. If a tachometer is available, adjust

idle. Check Specifications page for

correct idle speed.

Loading Trimmer Line

1. Cut one piece of line to recommended length.

2. Align arrows on top of knob with openings in eyelets.

3. Insert one end of trimmer line into an eyelet, and push line equal

distance through trimmer head.

4. Hold trimmer head while turning knob clockwise to wind line onto

spool until about 5” (13 cm) of each line remains exposed.

Trimmer head is now fully loaded and ready for operation.

.080 (2.0 mm) dia. - 10’ (3 m)

.095 (2.4 mm) dia. - 10’ (3 m)

1

2

3

4

NOTE:

Carburetor fuel mixture adjustments

are preset at factory and cannot be

serviced in the field

NOTE:

Trimmer head is pre-wound with .095" (2.4mm) Crossfire™

trimmer line.