Slant/Fin Jaguar J-390 User Manual

Page 6

Jaguar Model J-390

6

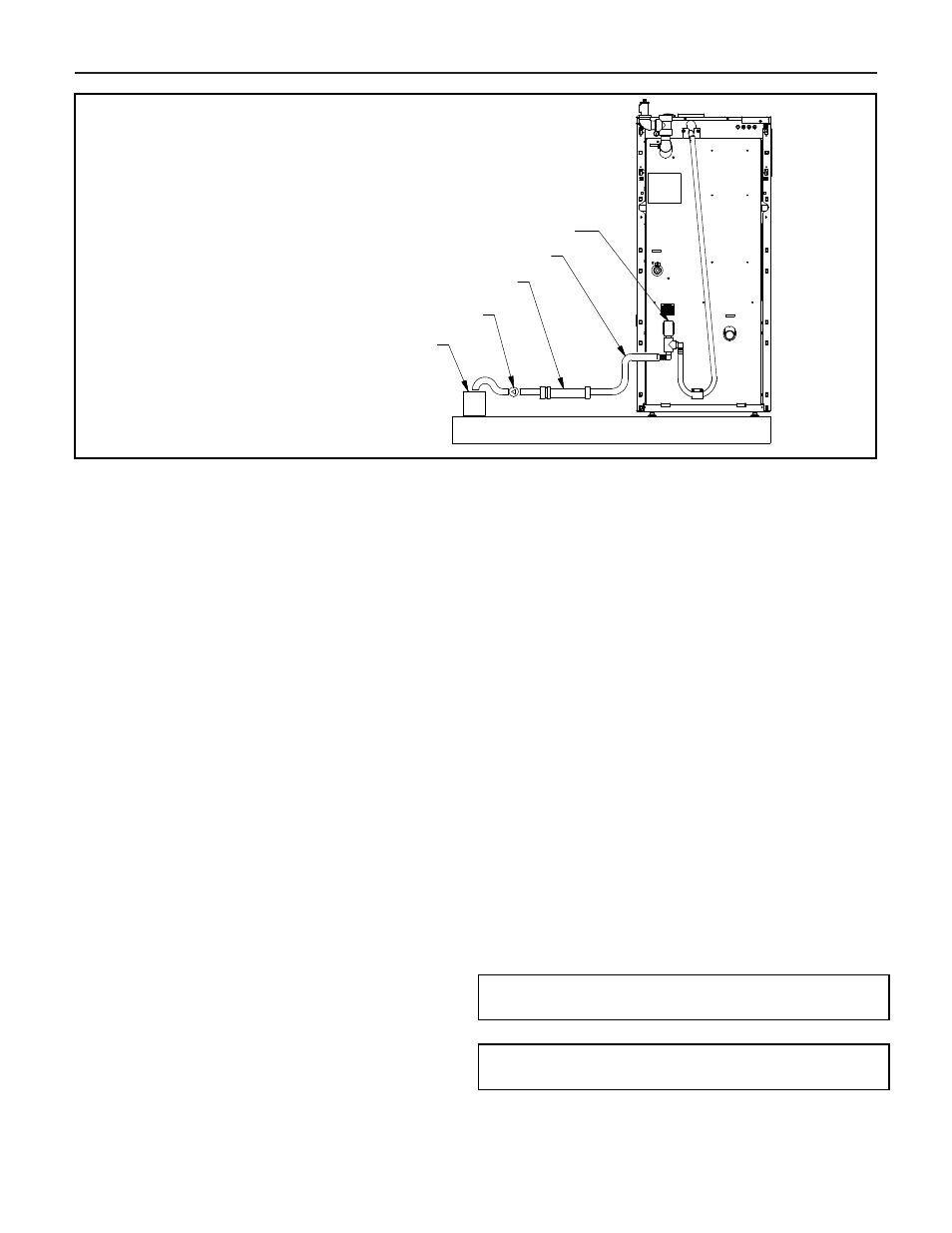

2. CONDENSATE REMOVAL SYSTEM

The Jaguar boilers is equipped with a built-in conden-

sation drain and trap. The trap must be filled with water.

DO NOT operate the boiler without filling the trap with

water to prevent flue gas discharge into space. Periodic

inspection should be made of this assembly for deterio-

ration of the tubing and to insure that the trap is not

plugged. If it is plugged or appears to have excessive

sediment in it, it should be removed from the drain

assembly, straightened out to clear the obstruction,

reformed, filled with water and reinstalled as before.

(See Figure 7).

Leave the top of the condensate drain tee open, to act

as a vacuum breaker. Do not allow any part of the

condensate removal system to be exposed to freezing

temperatures, or any other conditions that could cause

blockage.

If a neutralizing system is installed, the filter medium will

require periodic changing, to ensure it’s effectiveness.

Refer to the neutralizing unit’s manufacturers instruc-

tions, if available, or change the medium on an annual

basis.

3. PIPING INSPECTION

Look at all water piping. There should be no leaks or

signs of leaks at any pipe joints or around the boiler.

4. SYSTEM WATER PRESSURE INSPECTION

The boiler water pressure is indicated on the pressure

gage (See Figure 1 for location). The boiler water outlet

temperature is normally indicated on the temperature

display (See Figure 1 for location and Figure 9 for digits

illustration). For most installations, it should indicate

about 12 to 15 psi pressure when temperature is about

70 to 100F and from 15 psi to 25 psi when temperature

is up to 195˚F. FOR YOUR SYSTEM, there is one

correct pressure for each temperature. ASK YOUR

INSTALLER OR SERVICEPERSON TO EXPLAIN AND

SHOW YOU. Learn what normal pressure to look for. If

pressure increases from normal, the relief valve will

open to relieve the pressure. Call your service organiza-

tion if pressures are higher or lower than normal, and if

the relief valve spills water. Repair or adjustment is

needed.

5. UNUSUAL NOISE

Stand near the boiler and look and listen. As the burner

start and shut off, there should be no unusual noise.

6. BOILER ROOM AIR SUPPLY

Ample boiler room fresh air is required for combustion

(non-direct vent installation) and ventilation (direct-vent

installation).

Check air vents for continues positive supply of air as

required. Air needs are greatest in cold weather if boiler

installation is non-direct vent method. Air vents must be

open and free of obstruction.

Warning:

The flow of combustion and ventilating air to the

boiler should not be obstructed.

Warning:

If you find any problem during your inspection, call

for service immediately.

Figure 7. Condensate disposal system

NEUTRALIZING UNIT (IF REQUIRED)

CONDENSATE PUMP (IF REQUIRED)

DRAIN INSIDE BUILDING

PLASTIC TUBING

DRAIN VACUUM BREAKER, LEAVE OPEN