Troubleshooting, Maintenance – Woodstock 6" BENCH GRINDER M1051 User Manual

Page 17

-15-

M1051 6" Bench Grinder

MAINTENANCE

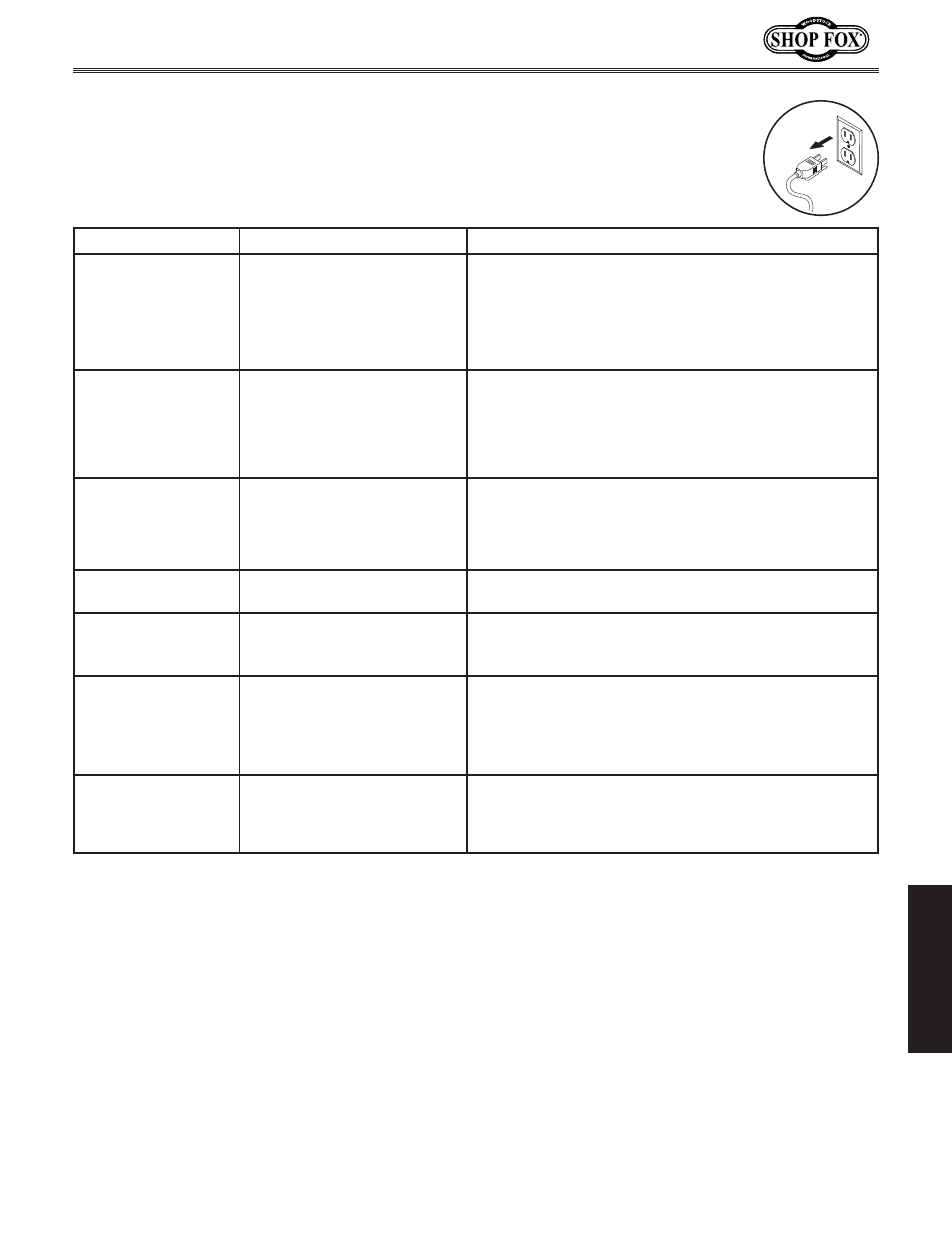

Troubleshooting

PROBLEM

Motor will not start; fuses

or circuit breakers blow.

Motor overheats, stalls

(resulting in blown fuses or

tripped circuit).

Wavy condition on surface

of workpiece.

Lines on surface of

workpiece.

Burning spots or cracks in

the workpiece.

Wheel dulls quickly, grit

falls off.

Wheel clogs and workpiece

shows burn marks.

POSSIBLE CAUSE

1. Open circuit in motor or loose

connections.

2. Start capacitor is at fault.

3. Short circuit in motor or loose

connections.

4. Incorrect fuses or circuit breakers

in power supply.

1. Motor overloaded.

2. Short circuit in motor or loose

connections.

3. Depth of cut too great.

1. Machine vibrating.

2. Workpiece is not held in place-

firmly.

3. Wheel face uneven.

4. Wheel is too hard.

1. Impurity on wheel surface.

2. Workpiece not being held tightly.

1. Improper type of grinding wheel.

2. Improper feed rate.

3. Coolant required.

1. Depth of cut too great.

2. Wheel is too soft.

3. Wheel diameter too small.

4. Bad wheel dress.

5. Defective wheel bonding.

1. Wheel is too hard.

2. Feed rate too slow.

3. Bad wheel dress.

CORRECTIVE ACTION

1. Inspect/repair all lead connections on motor for loose or open

connections.

2. Replace start capacitor.

3. Inspect all connections on motor for loose or shorted terminals or

worn insulation.

4. Install correct fuses or circuit breakers.

1. Reduce load on motor.

2. Inspect connections on motor for loose or shorted terminals or

worn insulation.

3. Slow down the rate of movement of the workpiece into wheel.

1. Make sure machine is securely mounted on a solid surface.

2. Use a holding device to firmly retain the workpiece.

3. Dress the grinding wheel.

4. Use softer wheel, or reduce the feed rate.

1. Dress the grinding wheel.

2. Use a holding device to firmly retain the workpiece.

1. Try a wheel which is softer style or a coarser grit.

2. Slow down the rate of movement of the workpiece into wheel.

3. Add optional coolant system or introduce coolant by hand.

1. Slow down the rate of movement of the workpiece into wheel.

2. Wheel too soft for the material being ground, select harder

bond.

3. Replace the wheel.

4. Dress the wheel.

5. Consult manufacturer of grinding wheel.

1. Wheel too hard for the material being ground, select softer

bond.

2. Increase the rate of movement of the workpiece into wheel.

3. Dress the wheel.

This section covers the most common problems and corrections with this type of

machine.

WARNING! DO NOT make any adjustments until power is disconnected and

moving parts have come to a complete stop!