Maintenance – State SW 37-670 User Manual

Page 17

17

MaIntenance

Boiler maintenance includes periodic tank flushing and cleaning, and

removal of lime scale from the heating elements. Circulating pumps

should be oiled.

MaIntenance schedule

Component

Operation

Interval

Required

Tank

Flushing

Monthly

Sediment

Removal

As Needed

Elements

Lime Scale

Removal

As Needed

UN•LIME

®

Delimer and

element gaskets

Circulating Pump(s)

Oiling

Per pump makers instructions

Pressure Relief

Valve Test

Manually

Operate

Anually

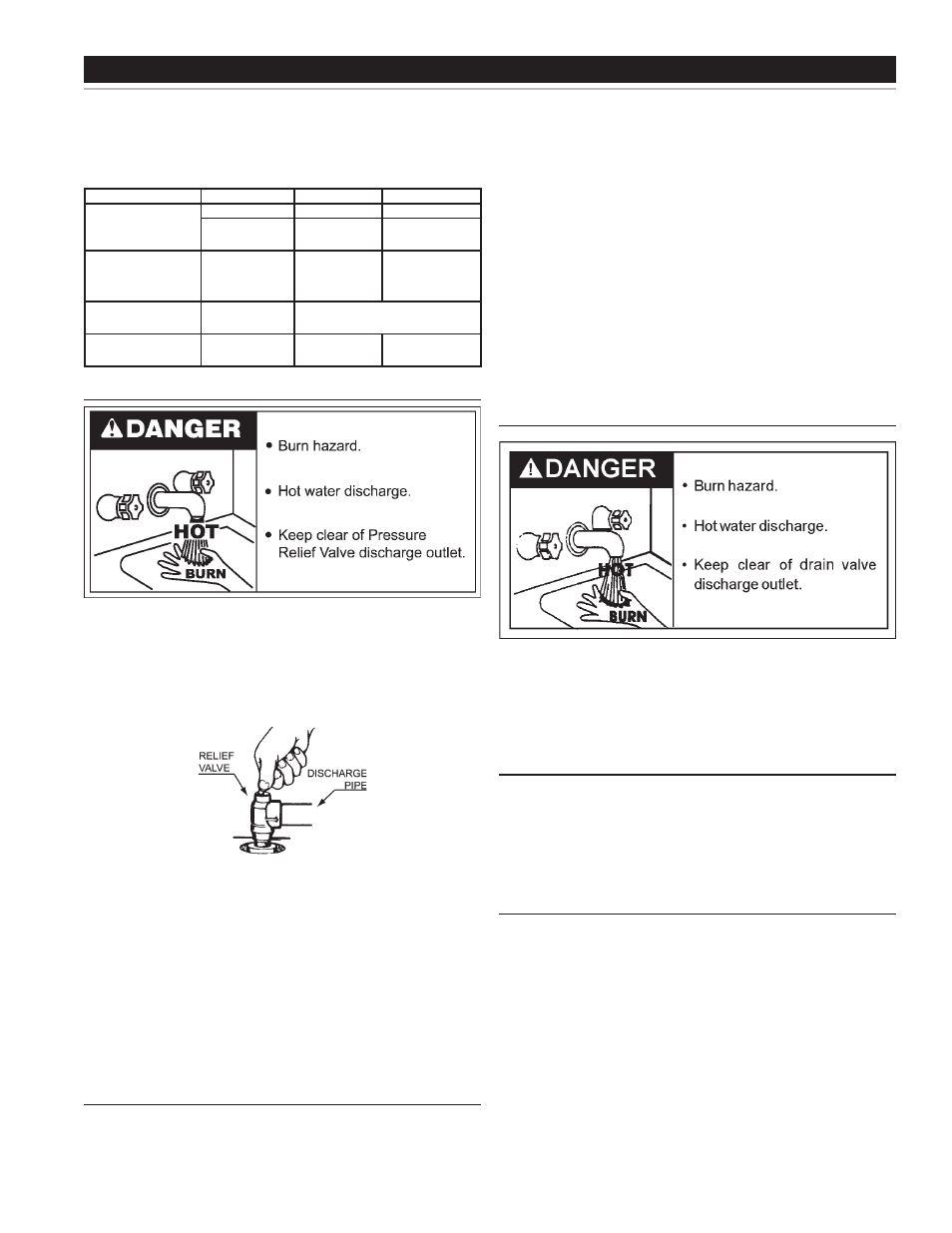

pressure relIef ValVe test

The pressure relief valve must be manually operated at least once a

year. Caution should be taken to ensure that (1) no one is in front of

or around the outlet of the pressure relief valve discharge line, and

(2) the water manually discharged will not cause any bodily injury or

property damage because the water may be extremely hot.

To test the relief valve, lift the lever at the end of the valve several times,

see Figure 2. The valve should seat properly and operate freely.

fIGure 2.

If after manually operating the valve, it fails to completely reset and

continues to release water, turn off power to the boiler at the main

disconnect switch or breaker. Close the cold water inlet to the boiler and

follow the draining instructions in this manual to drain the boiler. Should

the relief valve need to be replaced, call the toll free phone number

listed on the back of this manual for further technical assistance.

Tank flushing and circulating pump lubrication should be performed

in accordance with the above schedule. Tank sediment removal and

element lime scale removal must be performed when needed as

determined by period inspections. Following are the instructions for

performing recommended maintenance.

systeM cleanInG

The hot water system should be internally cleaned and flushed to

remove contaminants which may have accumulated during installation.

System cleaning provides chemical stability necessary for component

life and system performance.

Failure to clean the system may cause:

1. Poor heating due to formation of gas.

• Residential pipe dope, thread cutting oil, solder flux, dirt and other

foreign materials breakdown to form gas. This is indicated by a

continuing need for purging even through the system is “closed”.

2. Pump seal leakage.

• Acidic water (low pH) and contamination such as soil and sand

result in premature or recurring pump seal failures.

3. Automatic air valve leakage.

• Contaminants cause sticky sealing surfaces and result in leakage.

4. Relief valve operation.

• Gas formation increases system pressure and relief valve spillage.

5. Water leaks at joints and fittings.

• Corrosion and eventual failure of connections occur when

system pH is low.

6. Noisy operation.

• Heat transfer surfaces can be fouled with dirty, oily water. This

plus gas lead to noisy water circulation.

flushInG

1. Turn off the electrical disconnect switch.

2. Open the boiler drain valve. Allow water to flow to an open drain

until it runs clean. Do not come in contact with the water being

drained as it may be very hot.

3. Close the drain valve when finished flushing.

4. Turn on the electrical disconnect switch.

sedIMent reMoVal

Water borne impurities consist of fine particles of soil and sand which

settle out and form a layer of sediment on the bottom of the tank. In time,

if not removed, the level of sediment might reach the heating elements.

For convenience, sediment removal and element lime scale removal

should be performed at the same time as follows:

water and lIMe scale reMoVal

Water and lime scale accumulations on the heating elements is a

normal condition, common to all immersion type elements. Factors

which affect the amount of this formation are:

1. Amount of make-up water used. As the volume of make-up water

heated increases, more scale results.

2. Water temperature. As the temperature of the water is increased,

more scale is deposited on the elements.

3. Characteristics of water supply. Regardless of water treatment,

the elements should be examined regularly.

Water scale accumulations may cause noises to occur during operation.

It is recommended that a lower heating element be removed

periodically for examination. If it is scaled, all of the elements should

be removed and cleaned. If the tank bottom has an accumulation of

sediment, it should be cleaned.