Installation – State SW 37-670 User Manual

Page 10

10

requIred aBIlIty

Installation and service of this boiler requires ability equivalent to that

of a qualified agency (page 2) in the field involved. Plumbing and

electrical work is required.

General

The installation must conform with these instructions and the

local code authority having jurisdiction and the requirements of

the power company. In the absence of code requirements, follow

NFPA-70 (current edition). In the absence of local codes, the

installation must comply with the latest editions of the National

Electrical Code, NFPA 70 or the Canadian Electrical Code CSA

C22.1. The National Electrical Code may be ordered from:

National Fire Protection Association, 1 Batterymarch Park, Quincy,

MA 02269. The Canadian Electrical Code is available from the

Canadian Standards Association, 8501 East Pleasant Valley Road,

Cleveland, OH 44131.

Do

not test electrical system before boiler is filled with water,

follow the START UP procedure in the OPERATION section of this

manual.

The principal components of the boiler are identified in the Features

and Components illustration on page 8.

Boilers are usually placed in a series with the heating system on

the outlet side of the circulating pump. The boiler piping should

include inlet and outlet water valves to permit maintenance and

service work to be performed without disturbing the rest of the

system.

Detailed system installation drawings are normally provided by the

equipment purchaser or system designer.

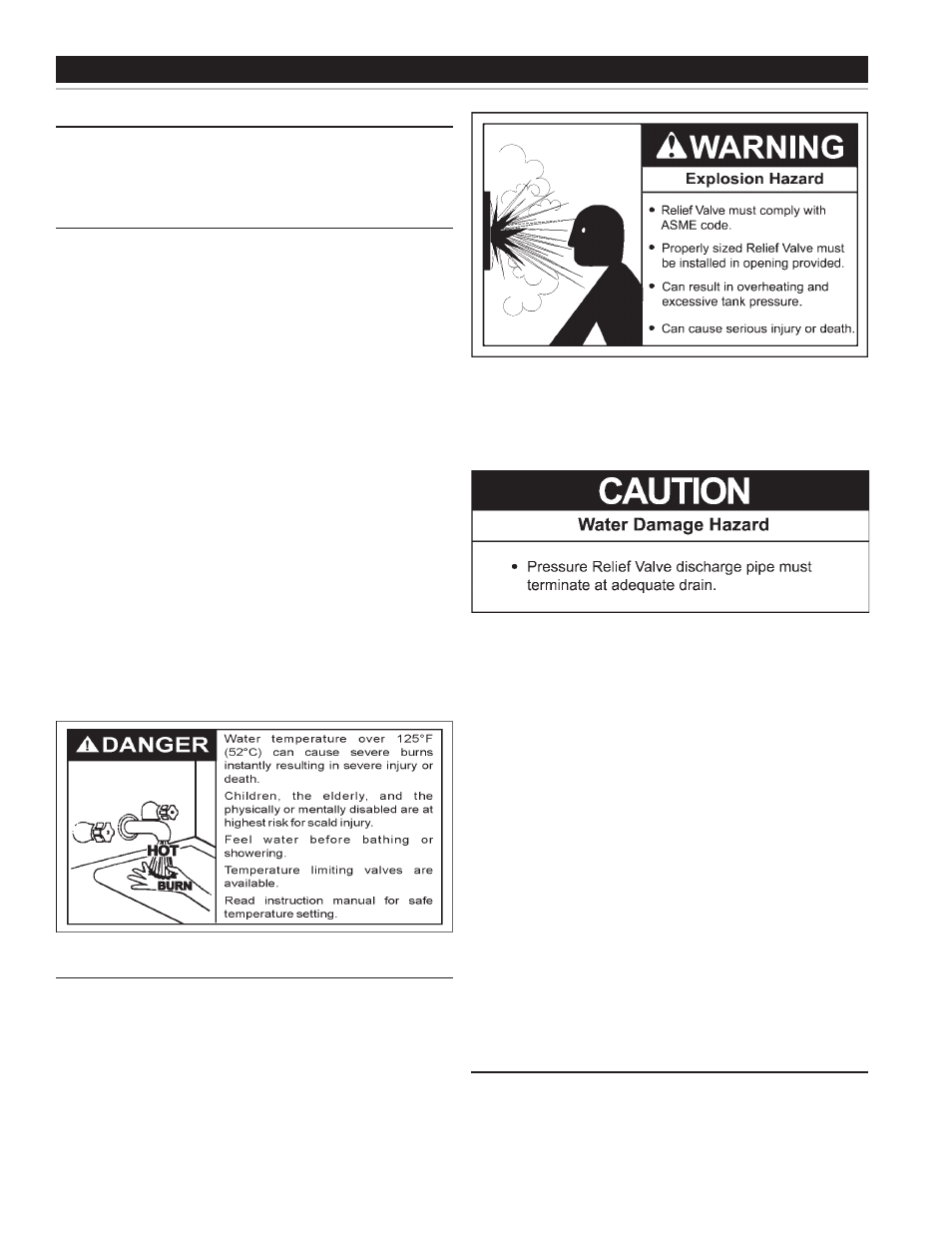

pressure relIef ValVe

An ASME rated pressure relief valve is furnished with the boiler. A

fitting for the relief valve is provided in the top of the boiler. Never

operate the heating elements without being certain the boiler is filled

with water and a properly sized pressure relief valve is installed in

the relief valve opening provided.

The pressure rating of the relief valve should be equal to or less

than the rated pressure capacity of any component in the system

including the boiler. Should the valve need to be replaced, call the

toll free phone number listed on the back of this manual for further

technical assistance.

A discharge pipe from the relief valve should terminate at an

adequate floor drain. Do not thread, plug, or cap the end of the

drain line.

The Discharge Pipe:

• Shall not be smaller in size than the outlet pipe size of the valve,

or have any reducing couplings or other restrictions.

• Shall not be plugged or blocked.

• Shall not be exposed to freezing temperatures.

• Shall be of material listed for hot water distribution.

• Shall be installed so as to allow complete drainage of both the

relief valve and the discharge pipe.

• Must terminate a maximum of six inches above a floor drain or

external to the building. In cold climates, it is recommended that

the discharge pipe be terminated at an adequate drain inside the

building.

• Shall not have any valve or other obstruction between the relief

valve and the drain.

Once the boiler is installed and filled with water and the system is

pressurized, manually test the operation of the pressure relief valve.

See the maintenance section of this manual forinstructions.

water lIne connectIons

The boiler may be installed by itself, or with a separate storage tank,

on both single and two-temperature systems. When used with a

separate storage tank, the circulation may be either by gravity or

by means of a circulating pump. When a circulating pump is used

it is important to note that the flow rate should be slow so that there

will be a minimum of turbulence inside the heater.

InstallatIon