Handling, Temporary storage, Type designations – Siemens 680 User Manual

Page 5: Ventilation, Introduction

- 4 -

Introduction

Handling

Lifting devices are provided for handling only. An

experienced rigger should be used to install motors.

To avoid damage, the use of spreader bars is recommended

on other than single point lifts. Lifting devices are provided to

facilitate handling with shackles and cables. Avoid pounding

or bumping shaft, coupling or bearing parts, as shocks may

damage bearings.

NOTE WEIGHT BEFORE LIFTING. The weight is indicated

on the outline drawing. Apply tension gradually to cables.

Do not jerk or attempt to move the unit suddenly.

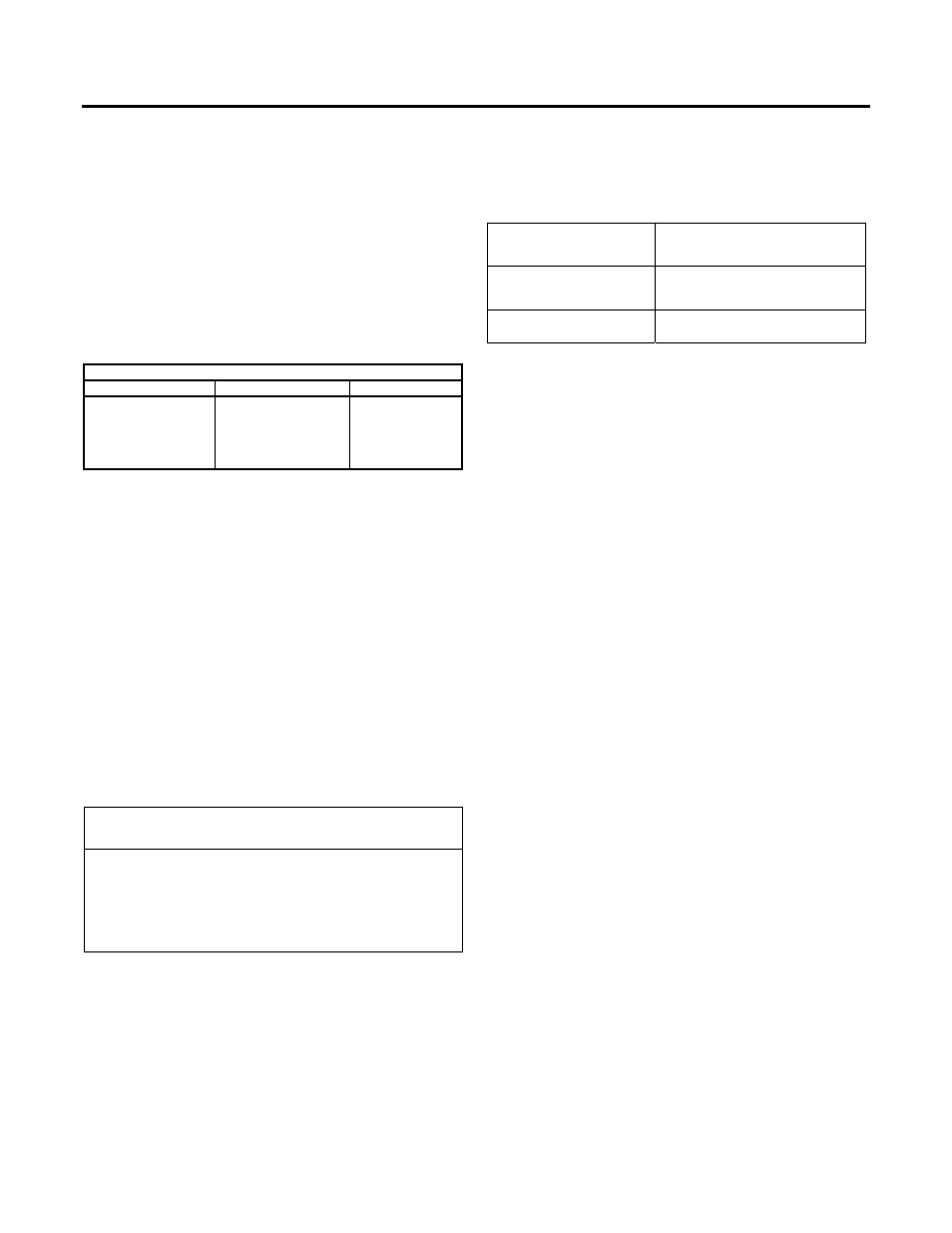

Motor Weights (in pounds)

Frame Size

Minimum

Maximum

500 2300

5400

580 4300

8400

680 10000

20000

800 15000

31000

1120 26000

37000

Temporary Storage

If the equipment is not to be installed and operated soon after

arrival, store it in a clean, dry, well- ventilated place, free from

vibration and rapid or wide variations in temperature. Rotate

the shaft a minimum of 10 complete turns by hand each

month to coat the bearings with lubricant which will retard

oxidation or corrosion, and prevent possible false brinelling.

If drain plugs are provided in enclosed motors, they must be

removed periodically to drain any water accumulation from

the motor. Consider a unit in storage when:

1. It has been delivered to the job site and is awaiting

installation.

2. It has been installed but operation is delayed over 30

days pending completion of plant construction.

3. There are long (30 day) periods between operating

cycles.

4.

The plant (or department) is shut down for 30 days.

NOTE

Storage requirements vary, depending on the length of

storage and the climate. For storage periods of three

months or longer or climate variations, consult Siemens

Storage Recommendations ANIM-03114. Storage

maintenance is to be documented for warranty

information.

Type Designations

The motor type designation consists of a basic letter or

letters indicating the motor enclosure type to which other

letters may be added denoting modifications.

Motor Type

Motor Enclosure

CGG or NCGG

Totally Enclosed

Water to Air Cooled

CAZ

Totally Enclosed

Air to Air Cooled

Ventilation

Type CGG, NCGG – 500 Frame and

Type CGG – 580, 680, 800 & 1120 Frame

The heated internal air from the hot stator core is directed to

an internally mounted heat exchanger where it is cooled and

recirculated back into the motor in a closed cooling loop. The

cooled internal air enters the motor from the heat exchanger

and non-metallic air baffles direct the air to an internal rotor

fan that circulates it through the rotor core, around the coil

ends, into the air gap, and through the vent ducts in the rotor

and stator cores. Heated air is exhausted through internal

openings in both sides of the motor and is directed to the

heat exchanger in the motor top cover. The hot internal air is

circulated over the finned surface of the heat exchanger. A

steady flow of cooling water provided by the customer enters

and exits the heat exchanger. Refer to motor outline drawing

for specific water inlet and outlet locations.

Type CAZ – 580, 680, & 800 Frame

The heated internal air from the hot stator core is directed to

an internally mounted heat exchanger where it is cooled and

recirculated back into the motor in a closed cooling loop. The

cooled internal air enters the motor from the heat exchanger

and non-metallic air baffles direct the air to an internal rotor

fan that circulates it through the rotor core, around the coil

ends, into the air gap, and through the vent ducts in the rotor

and stator cores. Heated air is exhausted through internal

openings in both sides of the motor and is directed to the

heat exchanger in the motor top cover. The hot internal air is

circulated over a series of cooling tubes in the heat

exchanger. A steady flow of cool ambient air is blown through

the cooling tubes by a shaft mounted external fan or an

auxiliary blower mounted on the heat exchanger. Refer to

motor outline drawing for specific air intake and exhaust

locations.