Caution, Maintenance – Siemens 680 User Manual

Page 22

- 21 -

Maintenance

Sleeve Bearings

CAUTION

Maintain proper oil level.

Failure to do so may cause improper lubrication of motor

resulting in damage to the equipment.

Follow lubrication instructions carefully. Avoid adding oil

while unit is running.

Motors with sleeve bearings are shipped without oil.

A rust-inhibiting film is applied at the factory to protect

bearing and journal surfaces during shipment.

Before attempting to operate any sleeve bearing

motor, the following steps must be performed.

1. Visually inspect the bearing condition. Oil ring

inspection ports and drain openings in the

housing are normally provided for this purpose.

2. Check for any accumulation of moisture. If

oxidation is discovered, all traces of it must be

removed before motor is put in service, which will

require disassembly.

3. Flush all oil piping. Fill bearing reservoirs to

normal level. Fill to mark indicated on gauge or

to center of gauge. See the table below for

recommended grades of oil.

4. Rotate shaft several turns by hand to distribute oil

over bearing parts. Make sure oil rings rotate

freely.

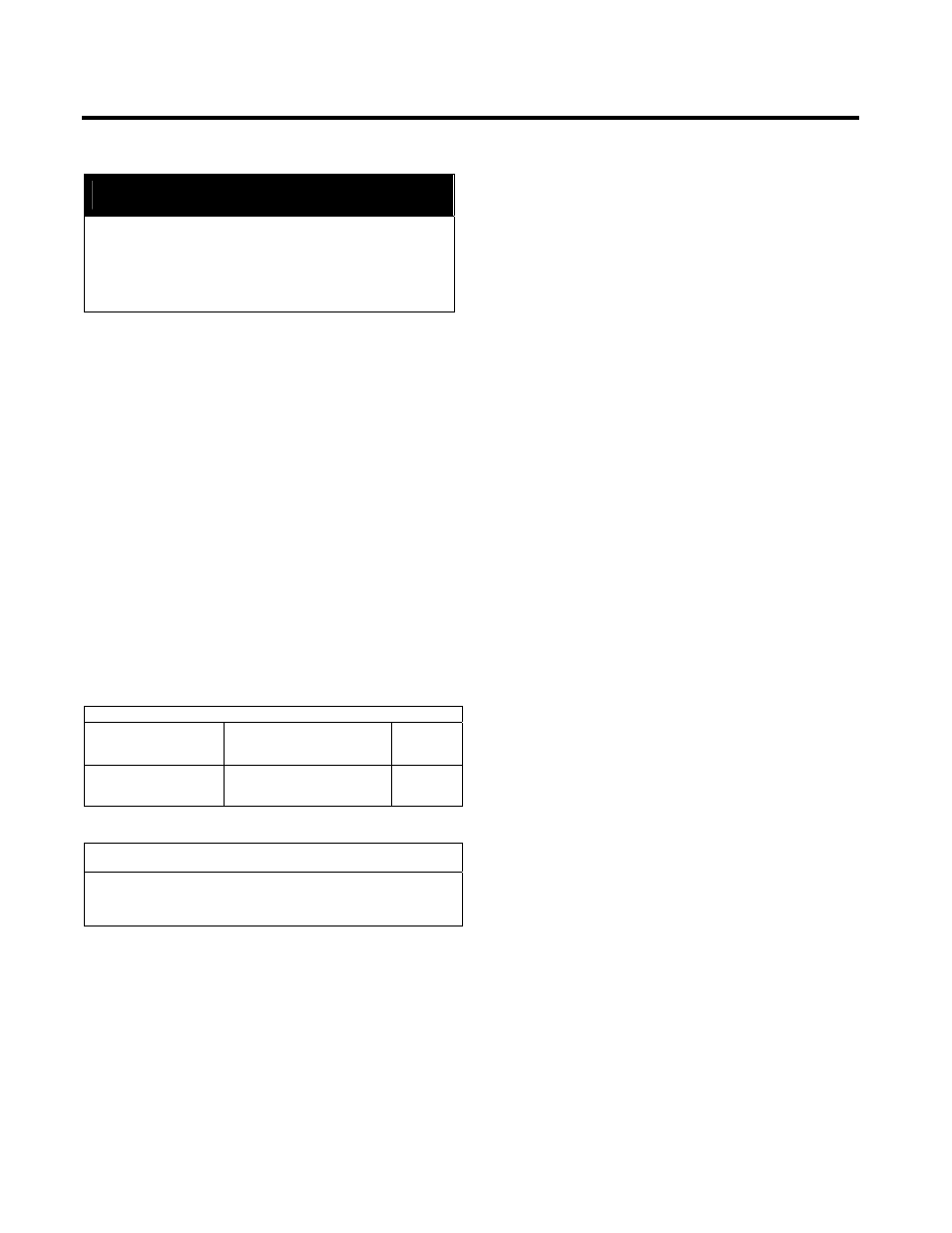

Recommended Grades of Turbine Oil

Motor Speed

Oil Viscosity at 100°F

ISO

Grade

3600 or 3000 RPM

1800 & slower

140 - 160 SSU

300 - 350 SSU

32

68

NOTE

The oil viscosity at operating temperature is very

important in selecting proper oil and may vary in

different climates.

It is important to maintain the correct oil level, as lack

of lubrication is often the cause of bearing failure.

Inspect oil level and oil ring operation frequently. Oil

ring operation can be observed through the sight

glass mounted at the top of the bearing capsule. Oil

rings should be perfectly round, free of burrs or rough

edges, turn at constant speed and carry a noticeable

amount of oil to the top of the journal. Failure of the

oil ring to turn freely may be caused by:

1. Ring out of round (should be round to 0.062 inch)

2. Fouling on a projection of the bearing bushing.

3. Ring not balanced (heavy side will tend to remain

down).

4. Adhesion to guide slot (trapezoidal section

reduces adhesion).

5. Oil too cold or viscous, or oil level too high.

6. Shaft not level – oil ring tends to bind.

At the first sign of oil discoloration or contamination,

replace with new oil. Rapid discoloration is caused

by bearing wear, often from vibration or thrust.

Change oil as required to keep clean.

Force Feed Lubrication

Oil is metered through an orifice in oil inlet line to

allow the proper amount of lubricating oil to enter the

bearing. Conventional oil rings are also supplied with

the motor to insure temporary bearing lubrication in

the event the force feed oil supply should fail. It is

important to check oil flow frequently. Lack of

lubrication may cause bearing failure.

Checking Sleeve Bearing Clearance

Excessive clearance can cause rapid bearing failure,

and decreased air gap between stator and rotor at

the bottom of the motor. Diametrical sleeve bearing

clearances for the 500, 580, 680, and 800 frame

motors are approximately 2 mils per inch of bearing

diameter. Diametrical sleeve bearing clearances for

the 1120 frame is in the range of 1.5mils per inch of

bearing diameter.

An accurate check of bearing clearance is obtained

with micrometer measurements of the shaft journal

and bearing bore.