Insulation resistance, Drying insulation, Caution – Siemens 680 User Manual

Page 17: Maintenance

- 16 -

Maintenance

Insulation Resistance

Check insulation resistance periodically. Use a hand

cranked or solid state insulation resistance tester and

test with at least 500 volts, but not greater than motor

rated voltage.

For motors with newer insulation systems such as

MICLAD™ VPI, the insulation resistance after one

minute should be greater than 1000 megohms.

(Values in excess of 5000 megohms are common.)

For older motors, the minimum value recommended

in IEEE Standard 43 can be used. The value in

megohms, when corrected to 40°C, is equal to the

motor rated voltage in kilovolts plus 1. For example,

for a motor with a rated voltage of 2300 volts, the limit

value would be:

2.3 + 1 = 3.3 (megohms).

Drying Insulation

If the insulation resistance is less than satisfactory,

and the cause is believed to be excessive moisture in

the windings, dry the windings by applying heat from:

1. A warm air oven.

2. Electric

strip

heaters.

3. Circulating

currents through the coils.

The heat should be applied slowly so the desired

temperature will not be obtained in less than six

hours.

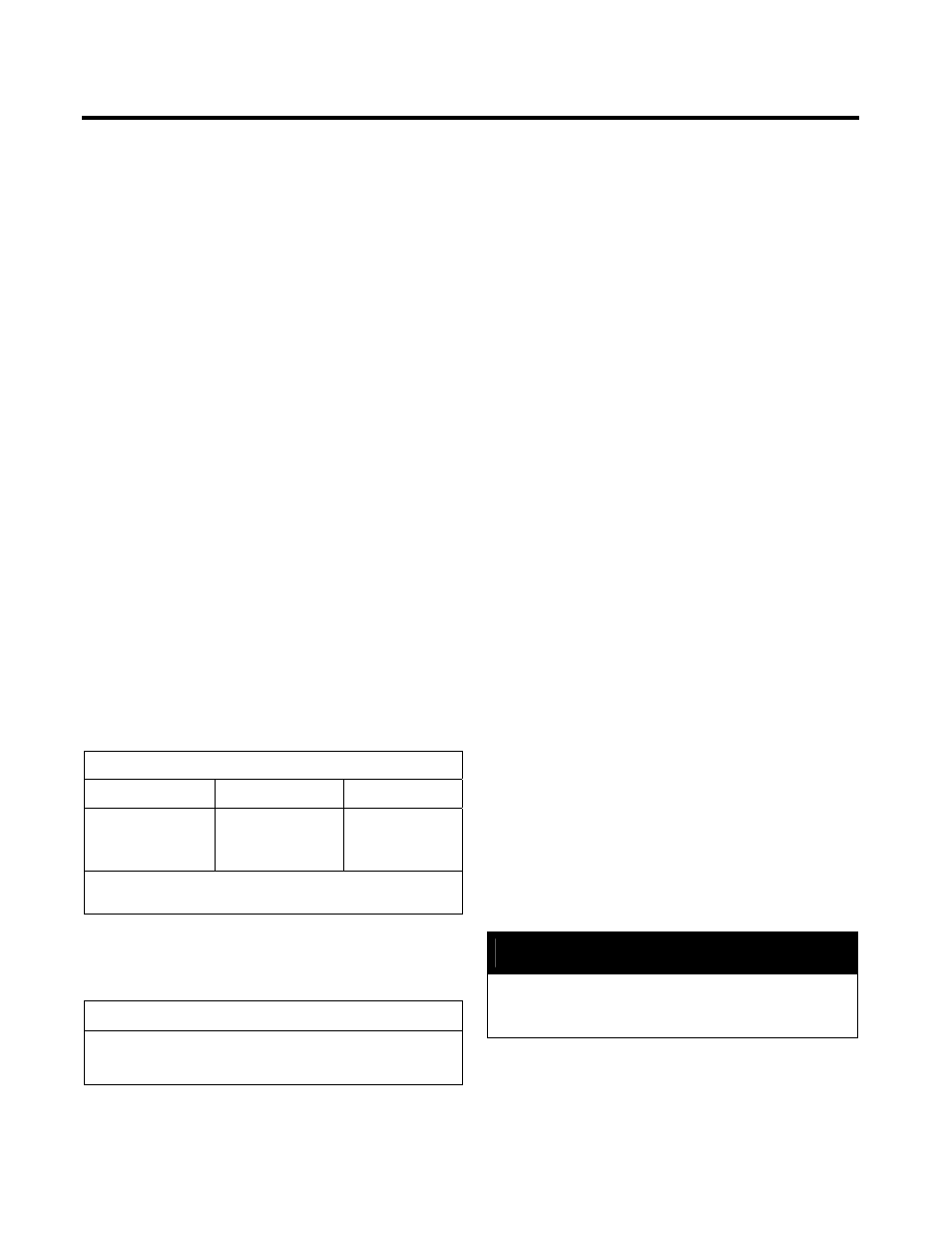

Insulation Drying Temperature*

Class “B”

Class “F”

Class “H”

200°F 245°F* 275°F*

94°C 118°C

135°C

*Class “F” and “H” insulated units should be baked at 70%

specified temperature (to avoid steam inside winding) for about

six hours, before temperature is raised to drying temperature.

Insulation resistance should be measured before the

heat is applied, and every six to eight hours

thereafter.

NOTE

Insulation resistance will decrease as the motor warms

up; but will begin to increase as the drying process

continues.

A uniform temperature must be maintained in the

motor to obtain constant resistance readings. When

the megger readings remain constant, the drying

process is complete and may be discontinued.

Check for other causes if readings are still low.

Warm Air Oven Drying

1. Remove bearing housings.

2. Remove

rotor.

Bake in oven at temperatures specified in Insulation

Drying Temperature table, and follow procedures

described for drying insulation.

Electric Strip Heater Drying

1. Remove bearing housings.

2. Remove

rotor.

3. Direct a fan on stator to carry away the moisture.

4. Attach temperature indicators to winding and

apply heat as specified in the Insulation Drying

Temperature table and follow procedures

described for drying insulation.

5. Radiant type heaters are not recommended

because some parts may become scorched

before remote parts reach desired temperature.

Circulating Current Drying

1. Remove bearing housings.

2. Center the rotor in the stator core.

3. Wedge fiber strips into the lower part of the air

gap so rotor does not touch stator core, or

remove rotor.

4. Direct fan on unit to blow away excessive

moisture.

5. Attach temperature indicators to windings. Do not

exceed the drying temperatures in the Insulation

Drying Temperature table.

6. An external source of current can be used to

circulate direct current through the winding of any

type of alternating current motor. A portable low

voltage motor-generator set, such as is used for

welding, is usually suitable.

CAUTION

High temperatures.

May cause damage to insulation.

Avoid hot spots and radiant type heat