Maintenance, When operating at 1.15 service factor load – Siemens 680 User Manual

Page 15

- 14 -

Maintenance

Sleeve Bearing – 500, 580, 680, 800 Frames

Access to the motor interior can be gained by

removal of the upper half of the horizontally split

bearing bracket.

1. Remove the parting bolts at the horizontal split.

2. Remove the bolts at the outer circumference of

the upper half of the split-bearing bracket.

3. Pull the upper bracket away from the face of the

frame and remove bracket.

The entire procedure can be done without disturbing

the bearing enclosure or coupling alignment of the

motor to the load. The split-bearing capsule is held

together by bolts.

Sleeve Bearing - 1120 Frames

Access to the motor interior can be gained by

removal of the bearing bracket as follows:

1. Remove the parting bolts at the horizontal split.

2. Carefully remove the top half of the bearing

housing by lifting it straight up and then pull it

away from the lower half.

Air Deflector

Air deflector construction depends on the type and

size of motor. The following conditions will be found

when accessing the motor interior;

1. 500 frame motors have air deflectors that are

retained in the fit between the bearing housing

and the stator yoke. Such air deflectors will be

removed with the bearing housing or can be

easily removed from the stator yoke after

bearing housing removal.

2. 580, 680, 800, or 1120 frame motors have air

deflectors which are mounted with bolts to the

stator yoke.

3. Air deflectors on sleeve bearing motors are

horizontally split.

Cleanliness

The exterior should be kept free of oil, dust, dirt,

water, and chemical. It is particularly important to

keep the air intake and exhaust openings free of

obstructions.

NOTE

If equipment is operated intermittently in very damp

locations, it should be protected by space heaters. To

retard corrosion, grease all machined fits when the

unit is reassembled after a maintenance check.

Loading

Overloading causes overheating and reduces

insulation life. A winding subjected to a 10°C

temperature rise above the maximum limit for its

class may have its insulation life halved.

Underloading a motor is improper as it lowers the

motor power factor and efficiency which results in

higher power cost.

Temperature

Electrical apparatus operating under normal

conditions becomes quite warm. Although some

places may feel hot to the touch, the unit may be

within limits. If checking total temperature by

winding resistance or imbedded detector (RTD), the

total temperature should not exceed the following:

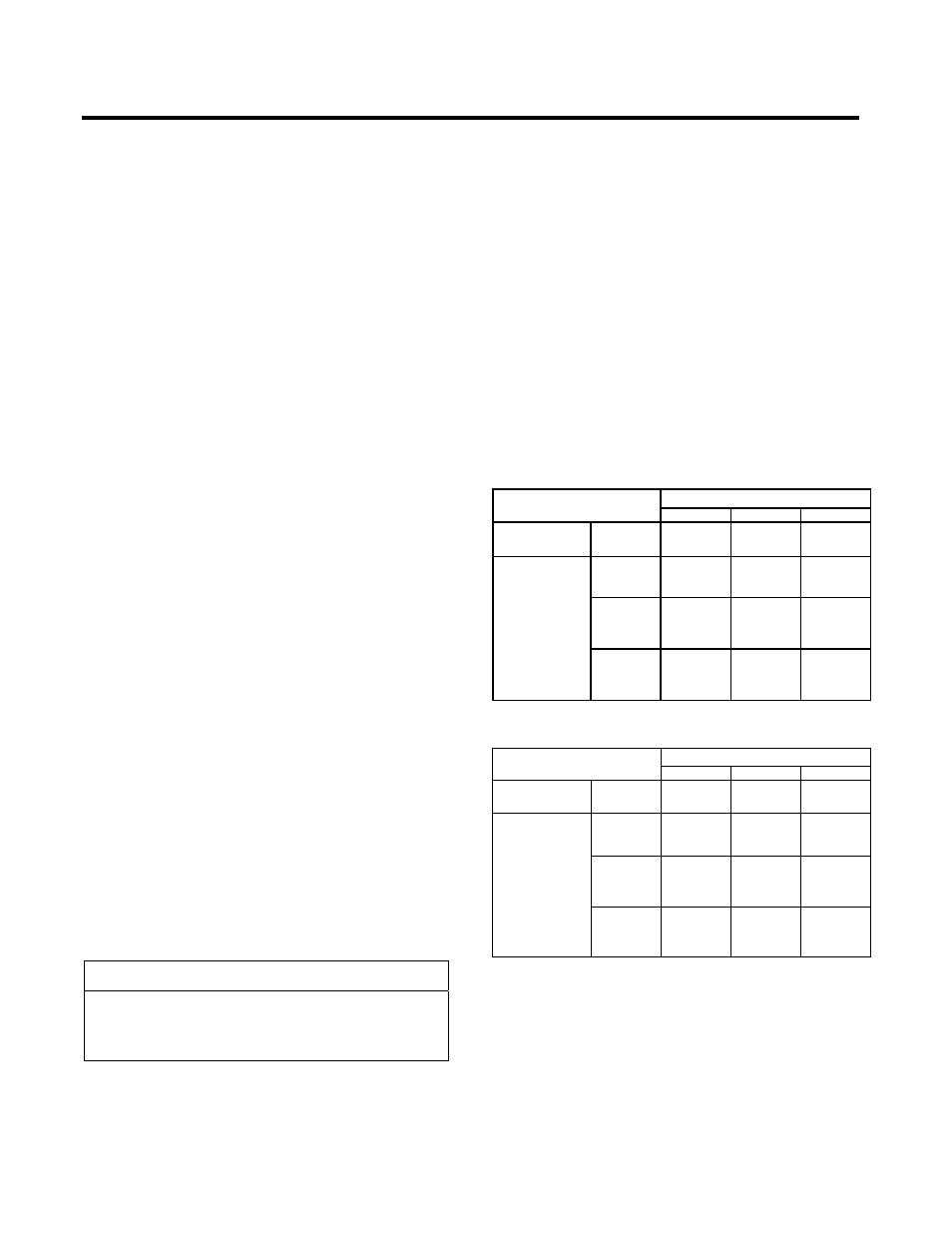

When operating at full load:

Class of Insulation System

B F H

Temp. by

Resistance

All HP

120°C

(248°F)

145°C

(293°F)

165°C

(329°F)

1500HP

or less

130°C

(266°F)

155°C

(311°F)

180°C

(356°F)

Over

1500HP

-Under

7000V

125°C

(257°F)

150°C

(302°F)

175°C

(347°F)

Temp. by

Embedded

Detector

Over

1500HP

-Over

7000 V

120°C

(248°F)

145°C

(293°F)

165°C

(329°F)

When operating at 1.15 service factor load:

Class of Insulation System

B F H

Temp. by

Resistance

All HP

130°C

(266°F)

155°C

(311°F)

175°C

(347°F)

1500HP

or less

140°C

(284°F)

165°C

(329°F)

190°C

(373°F)

Over

1500HP

-Under

7000V

135°C

(275°F)

160°C

(320°F)

185°C

(365°F)

Temp. by

Embedded

Detector

Over

1500HP

-Over

7000 V

130°C

(266°F)

155°C

(311°F)

175°C

(347°F)

These temperatures represent the maximum

temperature for each class of insulation and include

a 40°C ambient temperature. Operation above

these temperatures will result in reduced insulation

life.