Jackson AJ-44 User Manual

Page 47

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

CHANGING THE AJ-44CE/CS DIRECTION OF TRAVEL (CONTINUED)

39

Conveyor Switch Chart:

The chart above lists the conveyor switches and their func-

tions, depending on the direction of travel for the machine. As

you can see, when you change the direction of the conveyor,

you must also alter the way the conveyor switches operate.

There is no need to remove the switches, only to change the

wiring inside the heater box.

34. Note: Before beginning any part of this maintenance evo-

lution that deals with the wiring of the machine, ensure that it

is performed by qualified technicians only. Always refer to the

machine schematic, located inside the control box, for any

questions.

Wash Switch #1 and the Rinse Switch need to have their wire

positions changed on the terminal board pictured above.

Locate the gray/yellow wire for Wash Switch #1 (do not con-

fuse it with the gray/yellow wire for Wash Switch #2) and the

orange/yellow wire for the Rinse Switch. Exchange their posi-

tions on the terminal board.

35. Verify that the plumbing has been reassembled correctly

and that the hole cover weldment has been replaced and none

of the gaskets are torn or pinched as this could lead to leaking

when the machine operates.

35. Re-install the heater box cover.

SPECIAL PARTS

Gasket, Rinse Injector:

Mfg. No.: 05330-111-42-81

AFTER MAINTENANCE ACTIONS

1. Reconnect the incoming water and drain lines and

then restore power to the unit. Run the unit for at least 1/2

hour to ensure there are no leaks. Test the unit with an empty

rack to ensure that it pulls the rack all of the way through the

unit. If any problems arise you can contact your Jackson rep-

resentative.

2. Replace the front dress panel once the unit is

ready for service again.

SPECIAL NOTES

1. There is a possibility that you may be required to

shorten or lengthen the conduit and wire lengths for the inlet

solenoid on the rinse plumbing once it is moved. This work

should be performed by qualified technicians who will do the

work according to applicable local, state and national codes.

Questions concerning this should be directed to your Jackson

representative.

Unit

Direction

Switch #1

Switch #2

Switch #3

Left to Right

Wash Switch

#1

Wash Switch

#2

Rinse Switch

Right to Left Rinse Switch

Wash Switch

#2

Wash Switch

#1

Terminal board inside the heater box

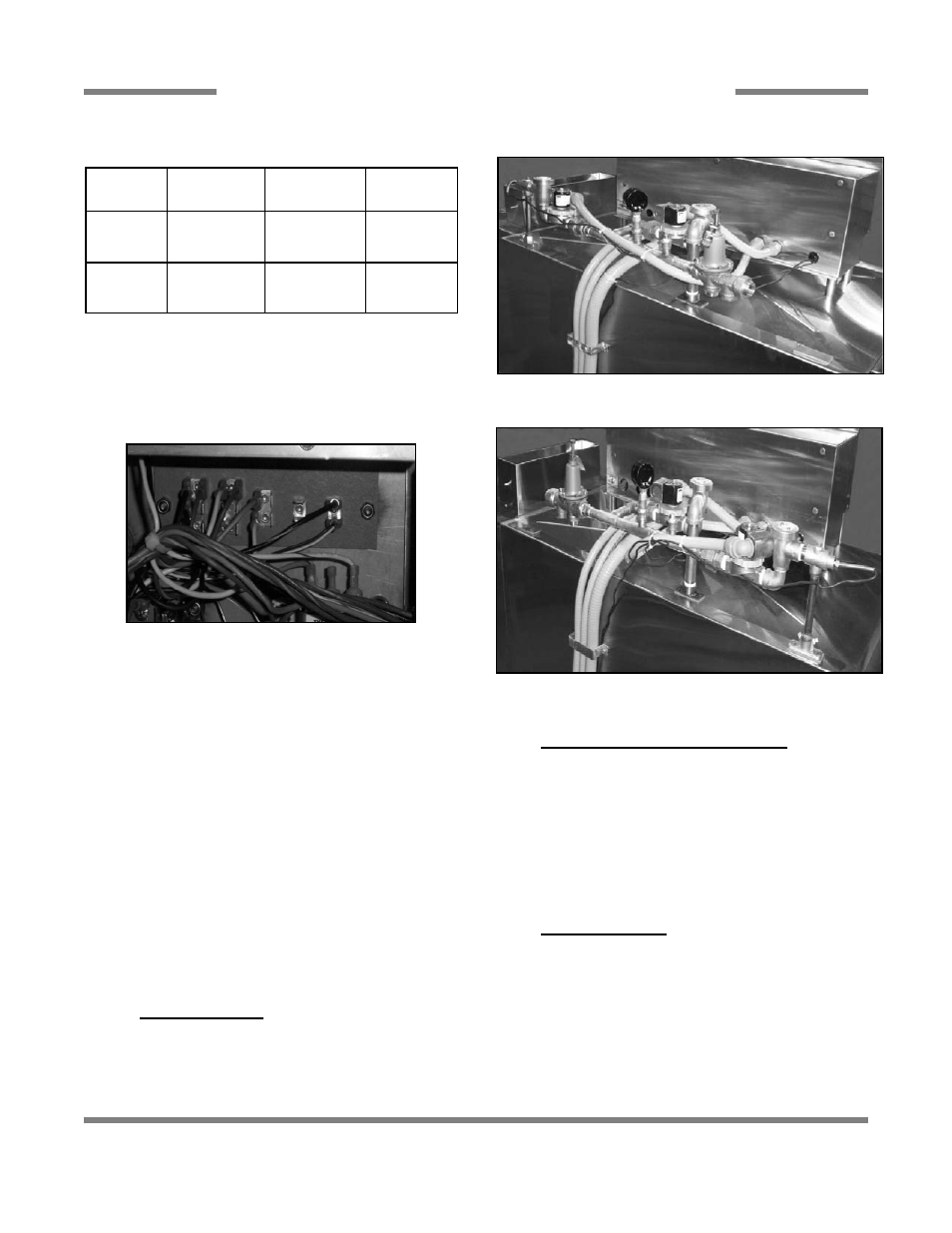

Incoming plumbing assembly for a Right to Left machine

(note hole cover weldment in upper left corner)

Incoming plumbing assembly for a Left to Right machine

(note hole cover weldment in lower right corner)