Checklist – Manitowoc Ice Chiplet QC0700 User Manual

Page 53

Part Number 000002688

5-1

Section 5

Before Calling Service

Checklist

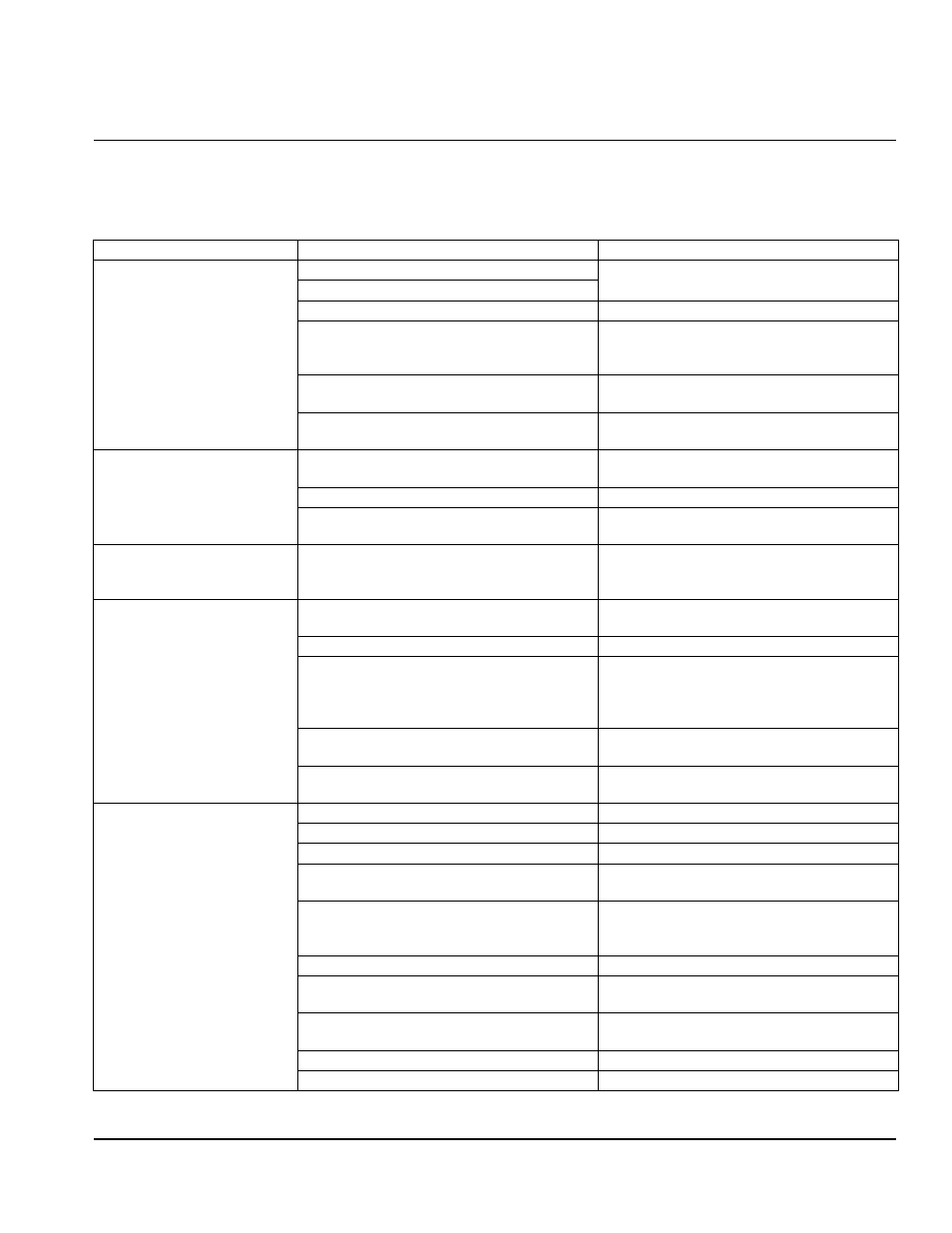

If a problem arises during operation of your ice machine, follow the checklist below before calling for service. Routine

adjustments and maintenance procedures are not covered by the warranty.

Problem

Possible Cause

To Correct

Ice machine does not operate.

No electrical power to the ice machine.

Replace the fuse/reset the breaker/turn on

main power switch/plug cord into receptacle.

Control Board fuse open

ICE/OFF/CLEAN toggle switch set improperly.

Move toggle switch to the ICE position.

8 minute lockout has not expired.

Bin level light will flash to indicate 8 minute

lockout has not expired. Refer to Sequence of

Operation

Bin level sensor is disconnected or is

contacting the ice.

Connect bin level sensor or remove ice

contacting probe.

High Pressure Control is open.

Clean condenser, check fan motor, check high

pressure control operation.

Gear Motor runs but

compressor will not start.

Water reservoir is empty. (Water must contact

the water level probe to start the compressor).

Open water service valve or clean float valve

screen.

Water level probes out of position

Correct water level probe position.

Remotes Only No electrical power to condensing unit

Replace the fuse/reset the breaker/turn on the

main power switch.

Ice machine stops and can be

restarted by moving the toggle

switch to OFF and back to ICE.

The SafeGuard feature is stopping the ice

machine.

Refer to “SafeGuard Feature” in this section

Ice quality is poor.

Poor incoming water quality.

Contact a qualified service company to test the

quality of the incoming water and check filter.

Water filtration is poor.

Replace filter.

Incoming water temperature is above 90

°

F

(32.3

°

C)

Correct water temperature. (Verify check/

mixing valves in other equipment are working

properly). Connect the ice machine to a cold

water supply.

Water pressure is low.

Water pressure must remain between 20 and

80 psig.

Water softener is working improperly (if

applicable).

Repair the water softener.

Low ice capacity.

Water float valve screen is dirty.

Remove and clean the filter screen.

Incoming water supply is shut-off.

Open the water service valve.

Water dump valve is leaking.

Clean the dump valve.

Water Pressure is low.

Water pressure must remain between 20 and

80 psig.

Incoming water temperature is above 90

°

F

(32.2

°

C)

Correct water temperature. (verify check/

mixing valves in other equipment is working

properly)

Water float valve stuck open or leaking.

Remove the float valve and clean it.

Air-Cooled Models Only Objects stacked around ice machine, blocking

airflow to condenser.

Remove items blocking airflow.

High air temperature around ice machine.

Air temperature must not exceed 110

°

F

(43.3

°

C)

Inadequate clearance around the ice machine. Provide adequate clearance.

The condenser is dirty.

Clean the condenser.