Section 5 − installation, 1. typical connection diagram for mig equipment – Miller Electric PipePro Dual User Manual

Page 17

OM-230 009 Page 13

SECTION 5 − INSTALLATION

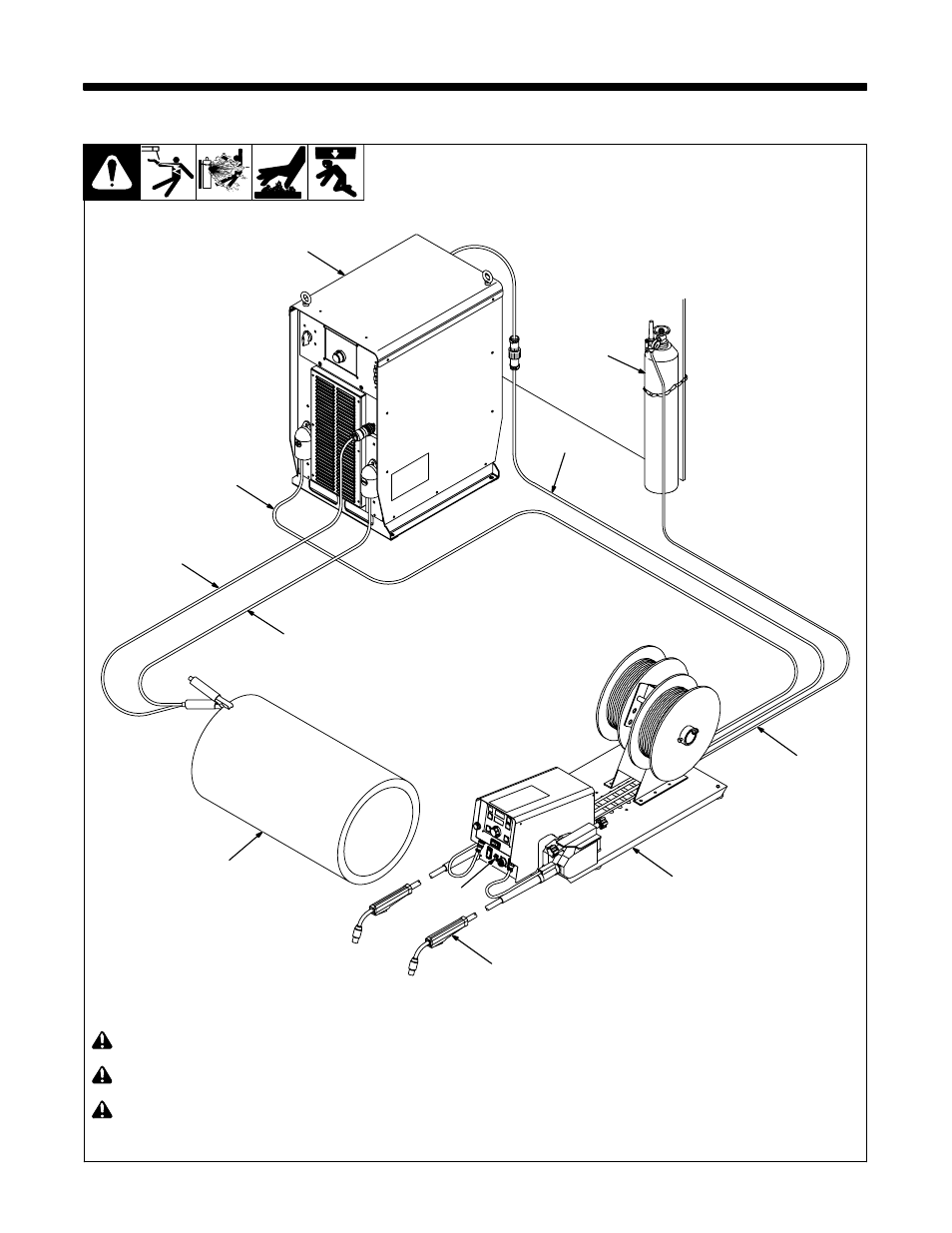

5-1. Typical Connection Diagram For MIG Equipment

!

Do not mount feeder on top of pow-

er source.

!

Do not put feeder where welding

wire hits cylinder.

!

Do not move or operate equipment

when it could tip.

1

Welding Power Source

2

Negative Volt Sense Cable

3

Positive (+) Weld Cable

4

Negative (−) Weld Cable

5

Workpiece

6

Welding Gun

7

Wire Feeder

8

Gas Hose

9

Gas Cylinder

10 14-Pin Feeder Control Cable

11 Remote Switch To MIG

.

Maximum cable length not to exceed

150 feet.

804 665-C

3

2

4

5

7

9

10

6

1

8

11

See also other documents in the category Miller Electric Tools:

- OM-2241 (32 pages)

- ICE-27C (36 pages)

- Arc Welding Power Source (4 pages)

- INVISION 456 CC (44 pages)

- Welder (132 pages)

- SS-75D12 (44 pages)

- Load Bank LBP-350 (2 pages)

- OM-193 084E (36 pages)

- 750MPa (2 pages)

- APT-1000 (20 pages)

- OM-220 390F (48 pages)

- 271 (48 pages)

- Welding (32 pages)

- DC (72 pages)

- OM-129 (70 pages)

- XLi (24 pages)

- S-64 (36 pages)

- ICE-27T (36 pages)

- PipePro 304 (76 pages)

- AA40GBU (28 pages)

- D-64 (40 pages)

- Auto Arc XLT 165 (48 pages)

- 185 DX (56 pages)

- S-32S (4 pages)

- Big 40 DC/TIG 55500 A (8 pages)

- Big Blue 600D (60 pages)

- Millermatic 140 (60 pages)

- pmn (36 pages)

- LMSW Series (2 pages)

- 1250 (46 pages)

- Trailblazer Pro 350 D (8 pages)

- TS (76 pages)

- S-22P12 (28 pages)

- 602 (40 pages)

- Axcess 300 (56 pages)

- MOG-400 (40 pages)

- WC-24 (20 pages)

- Big Blue 502P (64 pages)

- Dimension 1000 (44 pages)

- DS-74DX12 (52 pages)

- 350 VS (36 pages)

- 24A (32 pages)

- GA-16C (12 pages)

- Big Blue 502D (116 pages)

- OM-229 038D (36 pages)