Miller Electric Miller DU-OP User Manual

Page 26

OM-494 Page 22

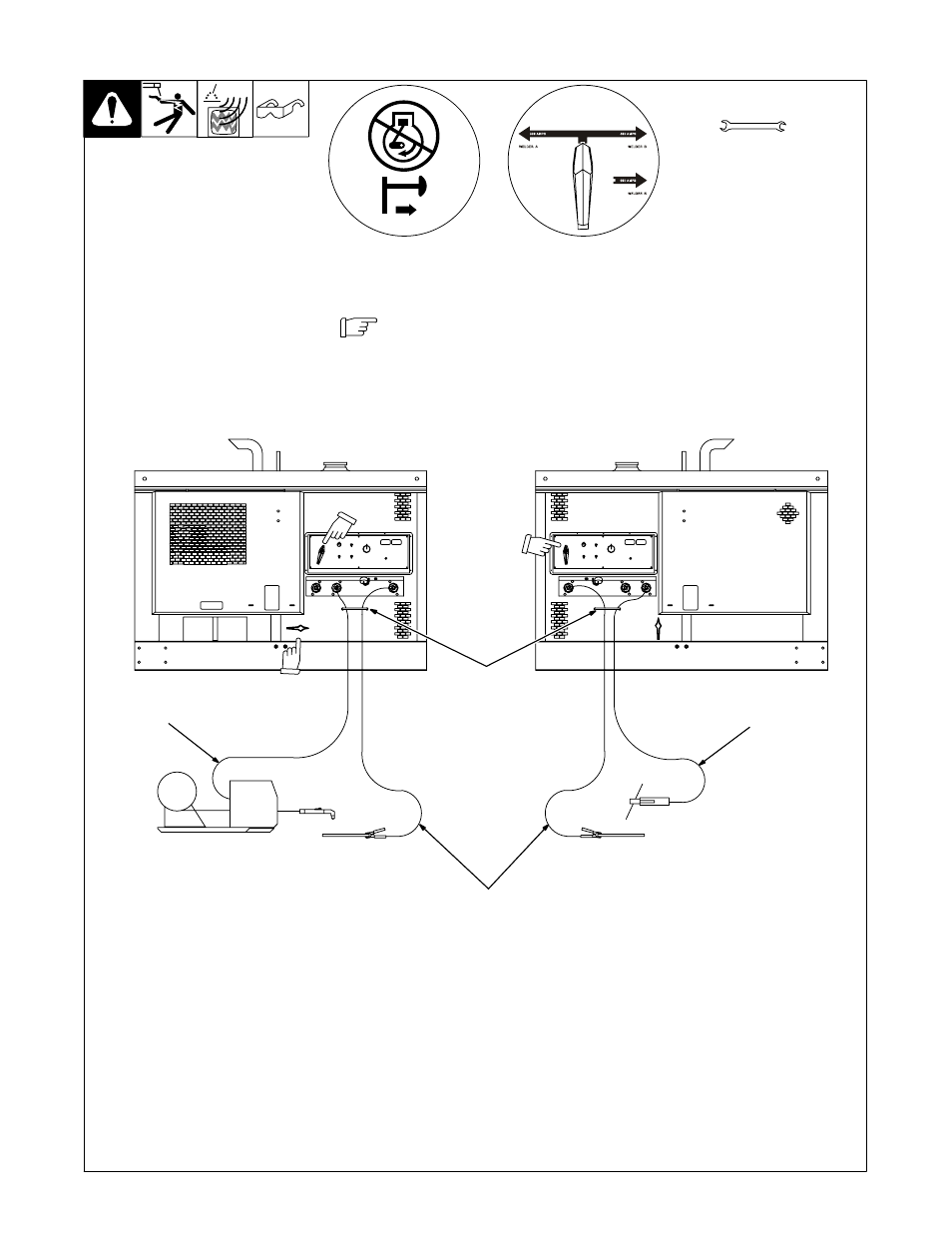

5-12. Making Dual Operator CC And CV Weld Connections w/ Separate Work Cables

Ref. 190 377 / 802 292-A

Y Stop engine.

Y Do not exceed machine duty cycle.

.

Use Dual Operator mode for CC and

See Section 5-15 for proper cable size.

1

Strain Reliefs

Route cables through strain reliefs.

2

Electrode Holder Cable

3

Wire Feeder Cable

4

Work Cables

For Stick/TIG welding Direct Current Elec-

trode Positive (DCEP), connect work cable

to Negative (−) terminal and electrode hold-

er cable to CC terminal.

For Stick/TIG Direct Current Electrode

Negative (DCEN), connect work cable to

CC terminal and electrode holder cable to

Negative (−) terminal.

.

Be sure Process Selector switches are

set correctly. See Section 6-3.

For MIG and FCAW welding Direct Current

Electrode Positive (DCEP), connect work

cable to Negative (−) terminal and wire

feeder cable to CV terminal.

For MIG and FCAW Direct Current Elec-

trode Negative (DCEN), connect work

cable to CV terminal and wire feeder cable

to Negative (−) terminal.

For Stick/TIG welding on units with Polarity

switch option, connect work cable to Work

receptacle and electrode cable to Electrode

receptacle.

For MIG/FCAW welding on units with Polar-

ity switch option, connect work cable to

Work receptacle and wire feeder cable to

CV receptacle.

.

Place optional Polarity switches in Re-

verse position when using CV weld re-

ceptacles. There is no CV weld output

when switch is in Straight position.

.

Be sure Process Selector and Polarity

switches are set correctly. See Section

Tools Needed:

Welder A (Left) Side

3/4 in

Welder B (Right) Side

1

2

3

4

Direct Current Electrode Positive

(DCEP) connections are shown.

Note position

of Process

Selector

switches.

Note position

of optional

Polarity

switch.