Inspection – Millennium Enterprises GME-P100 User Manual

Page 21

INSPECTION

(Before and After Each Use)

• Inhalation valve discs

• Exhalation valve disc

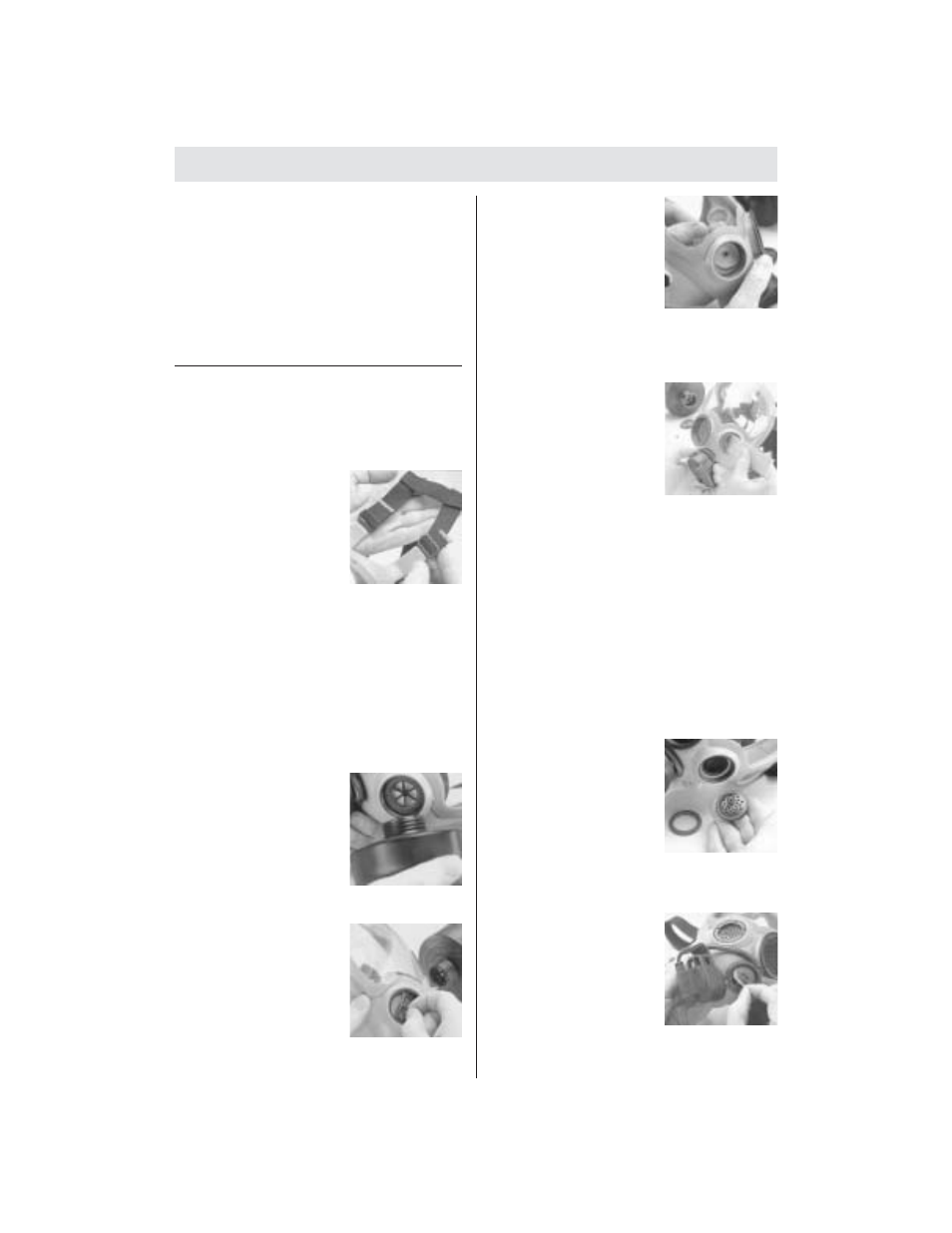

• Harness straps

• Lens

• Cartridge/canister

• Facepiece blank

• Accessories

INSPECTION PROCEDURES

1. Look for breaks or tears in the facepiece

head-strap material.

2. Make sure all straps,

fasteners, and ad-

justers are in place

and not damaged.

3. Check the facepiece for dirt, cracks,

tears, or holes.

4. Check the lens for cuts, scratches, or

damage which would impair vision.

Squeeze the lens. It should collapse

easily between your fingers. Check that

the lens is secured in the facepiece.

5. Look at the shape of the facepiece for

distortion due to improper storage.

6. Unthread the car-

tridge/canister (if

installed), and check

that the spider gasket,

inhalation valve, and

deflector nose cup are

installed and undam-

aged.

7. Grasp the spider gas-

ket by the raised tabs

and pull it gently out

of the facepiece. The

gasket must be free of

cracks, tears, dirt, and

distortion. The gasket

must be soft and flexible.

8. Reach into the face-

piece and remove

deflector and inhala-

tion valve. The deflec-

tor and inhalation

valve must be free of

cracks, tears, dirt, and

distortion. The inhalation valve must be

soft and flexible.

9. Set these parts aside in a clean location.

10. Insert the P/N 461828

spanner wrench into

the side voice-mitter

retaining ring. Turn the

ring counter-clockwise

to unthread.

11. Remove the side voice-mitter (smaller

port on the side of the facepiece) from

the port. The voice-mitter may need

pushed from inside of facepiece to

remove.

12. Inspect the side voice-mitter for signs of

damage which would let contaminant

enter the facepiece.

13. Inspect the front voice-mitter (large port

in the center of the facepiece below the

lens) for signs of damage which would

let contaminant enter the facepiece.

14. Carefully remove the

voice-mitter gasket

from the port. Gasket

must be free of cracks,

tears, dirt, and distor-

tion. The gasket must

be soft and flexible.

15. Set the gasket aside in a clean location.

16. Remove the rubber

cover from the exhala-

tion valve. Lift the

valve and inspect the

seat and valve for

cracks, tears, dirt, and

distortion. The valve

must be soft and flexible.

21

TAL 403 (L) Rev. 4 - 430351

INSPECTION