Murphy Digital Tach/Hourmeter with Overspeed Trip Point SHD30 User Manual

Warning, Description, Specifications

SHD3-97051N 1 of 4

Digital Tach/Hourmeter with Overspeed Trip Point

Installation Instructions for SHD30 and SHD30-45 Models

SHD3-97051N

Revised 05-03

Replaces SHD-96113N

Section 20

(00-02-0288)

Description

The SHD30 and SHD30-45 models are microprocessor-based digital

tachometers with hourmeter and overspeed trip point. The overspeed trip

point can be connected as either a form “C” relay output or as a normally

open SCR output.

In Class I, Div. 2, hazardous locations the SHD30 form “C” relay contact is

restricted for use with Murphy non-incendive or intrinsically-safe instruments. In

non-hazardous locations the relay contact may be used to switch resistive loads not

exceeding 0.5 A @ 30 VDC or 125 VAC.

When connected as a normally open SCR, the output is rated 0.5 A, 350 VDC

continuous and can switch up to 3 A @ 350 VDC momentary. The SCR output

may be used to switch designated normally open sensor inputs.

Specifications

Power input:

CD ignition: 90 to 350 VDC. 150 µA typical @ 90 VDC; 300 µA @ 350 VDC.

Magnetic Pickup: 5 to 120 Vrms.

325 µA typical @ 5 Vrms, 100 Hz; 450 µA typical @ 5 Vrms, 1 kHz;

1 mA typical @ 5 Vrms, 5 kHz; 2 mA typical @ 5 Vrms, 10 kHz;

15 mW max. @ 5 Vrms, 10 kHz; 2.8 W max. @ 120 Vrms, 10 kHz.

Backup Battery: 2 replaceable, long life Lithium batteries, Panasonic CR2032

or equivalent, 3 V, 220 mAh power.

Operating Temperature: -4° to 158°F (-20° to 70°C).

Storage Temperature: -40° to 300°F (-40° to 150°C).

Ignition Frequency Range: 3 to 666 Hz.

Magnetic Pickup Frequency Range: 1 to 10 kHz.

Overspeed Output:

Connected to S.C.R. (Silicon Controlled Rectifier) terminals:

0.5 A, 350 VDC continuous.

Connected to Form “C” Relay terminals:

Relay Contact, 0.5 A, 30 VDC, 125 VAC resistive.

Tachometer Accuracy: ±0.5% of the display reading or ±1 RPM

whichever is greater.

Hourmeter Range: 0 to 65535 hrs.

Hourmeter Accuracy: ±15 minutes per year.

Approvals: CSA approved for Cl. I, Div. 2, Grps. C & D hazardous areas.

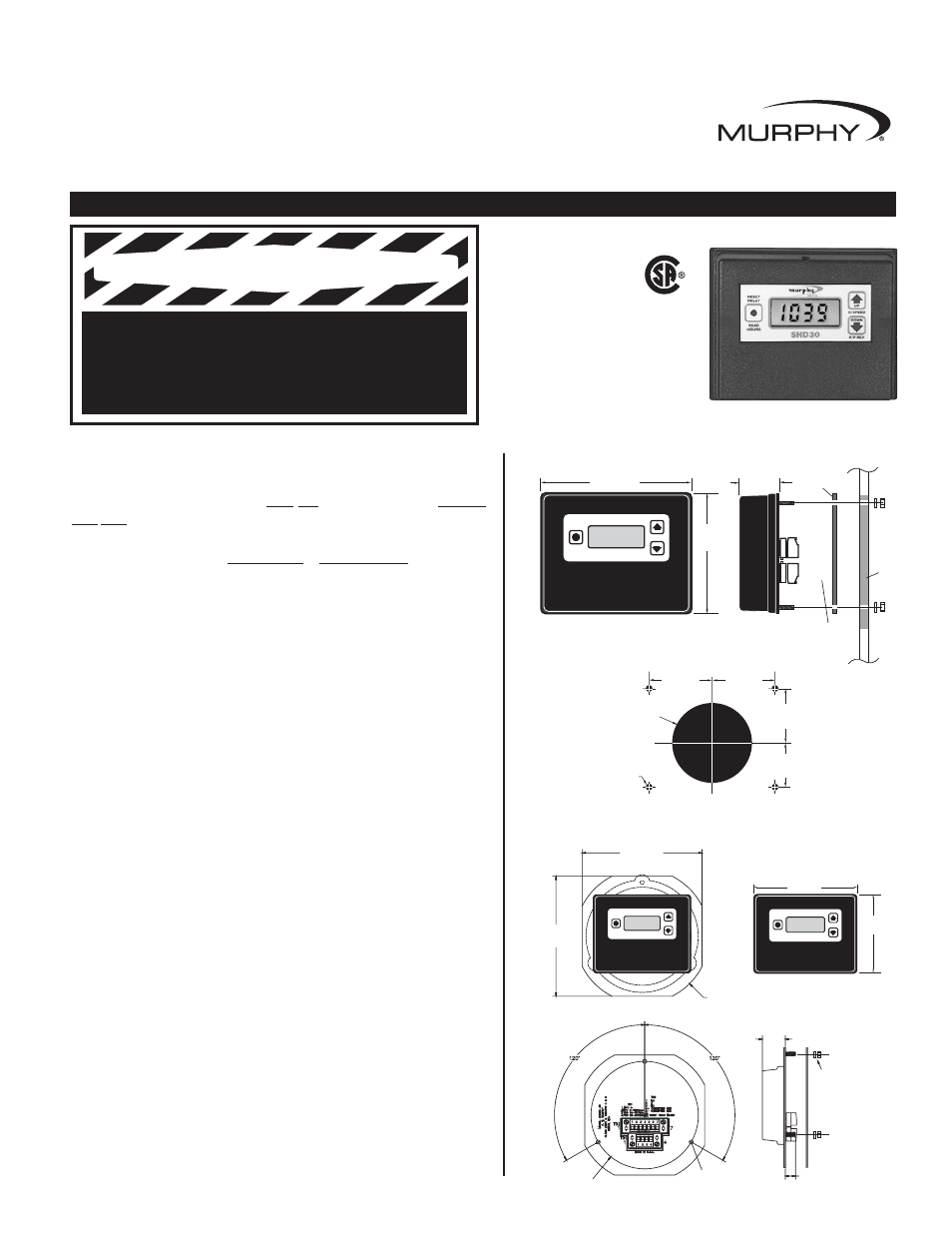

Mounting

The SHD30 is designed for installation in panels from 0.032 to 0.125 in. (1 to

3 mm) thick. A round hole, 3-1/8 in. (79 mm) in diameter is needed for

mounting. Install the unit within a weatherproof enclosure to protect it from

the elements. Keep the unit away from ignition coils and coil leads; a mini-

mum of 12 in. (305 mm) is recommended.

Please read the following information before installing. A visual inspection for any damage which may have occurred during shipping is

recommended. It is your responsibility to have a qualified person install the unit, and make sure it conforms with NEC and local codes.

GENERAL INFORMATION

panel

gasket

Terminal

Blocks

4-1/4 in.

(108 mm)

5-1/16 in.

(129 mm)

1-9/32 in.

(33 mm)

2 in.

(51 mm)

2 in.

(51 mm)

1-1/2 in.

(38 mm)

2 in.

(51 mm)

3/16 in

(5 mm)

diameter,

4 places

3-1/8 in.

(79 mm)

diameter

WARNING

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔

Disconnect all electrical power to the machine.

✔

Make sure the machine cannot operate during installation.

✔

Follow all safety warnings of the machine manufacturer.

✔

Read and follow all installation instructions.

SHD30 Dimensions

SHD30-45 Dimensions/Mounting

Mounting Hole

Approved for Class I, Division 2,

Groups C & D Hazardous Areas

When installed per Murphy

Drawing 20-08-0258

C US

S

C

R

=

0

.5

A,A

,

3

0

0

VdV

d

c

C

D

I

G

N

9

0

-3

0

0

VdV

d

c

T

YP:Y

P

:1

5

0

u

A A

@ @

9

0

VdV

d

c;

6

0

0

u

A

@ @

3

0

0

VdV

d

c

M

PUP

U

5

VaV

a

c-

1

2

0

V

a

c

T

YPY

P

:

3

2

5

u

A A

@

5

V

a

c,

1

0

0

H

z;

4

5

0

u

A@ A

@

5

VaV

a

c

1

kH

z;

1

5

m

w

M

A

X X

@

5

V

a

c,

1

0

kH

z;

2

.8

W

M

AXA

X

@ @

1

2

0

VaV

a

c,

1

0

kH

z

IN

S

T

A

L

L

E

C

O

N

F

O

R

M

E

M

E

N

T

M

U

R

P

H

Y

2

0

-0

8

-0

2

5

8

M

U

S

T

B

E

I

N

S

T

A

L

L

E

D

P

E

R

M

U

R

P

H

Y

D

W

G

.

2

0

-0

8

-0

2

5

8

1

m

A A

@ @

5

VaV

a

c,

5

kH

z;

2

m

A A

@

5

V

a

c,

1

0

kH

z;

O

U

T

P

U

T

R

ELE

L

AY A

Y

=

0

.5

A

,

3

0

VdV

d

c,

1

2

5

VdV

d

c

re

s

4-1/4 in.

(108 mm)

5-1/16 in.

(129 mm)

5-13/16 in.

(148 mm )

1-5/16 in.

(33 mm )

1/2 in.

(12 mm )

KEPS Nuts

(3 Supplied)

Ø

6-1/2 in.

5-13/16 in.

(148 mm )

Ø

5-13/64 in.

1/4 in. (6 mm ) dia. holes

(3 places)

Front View

Rear View

Side View