Warning, Caution, 3 - assembly instructions – McCulloch MCM2013 User Manual

Page 6

TO ADJUST SAW CHAIN TENSION:

1. Loosen the bar retaining nuts (D) so they are hand

tight. (See Fig. 3-5B)

2. Holding the nose of the bar up, use the screwdriver or

scrench if provided in your User’s Kit to turn the guide

bar adjustment screw (E) (Fig. 3-5C) clockwise to

tighten the chain. Turning the screw COUNTER-

CLOCKWISE LOOSENS THE CHAIN on the guide

bar.

3. After adjustment and while wearing heavy duty work

gloves, move the saw chain back and forth on the

guide bar to be sure the chain moves freely and is in

proper mesh with sprocket. Do not move chain with

bare hands.

NOTE: IF the chain is difficult to rotate or if it binds on the

guide bar, too much tension has been applied and must be

adjusted. To decrease tension, turn the adjustment screw

counterclockwise slowly. Move the chain back and forth

until it moves freely.

4. Holding the nose in upper position, securely tighten the

bar retaining nuts (70 inch lbs.)

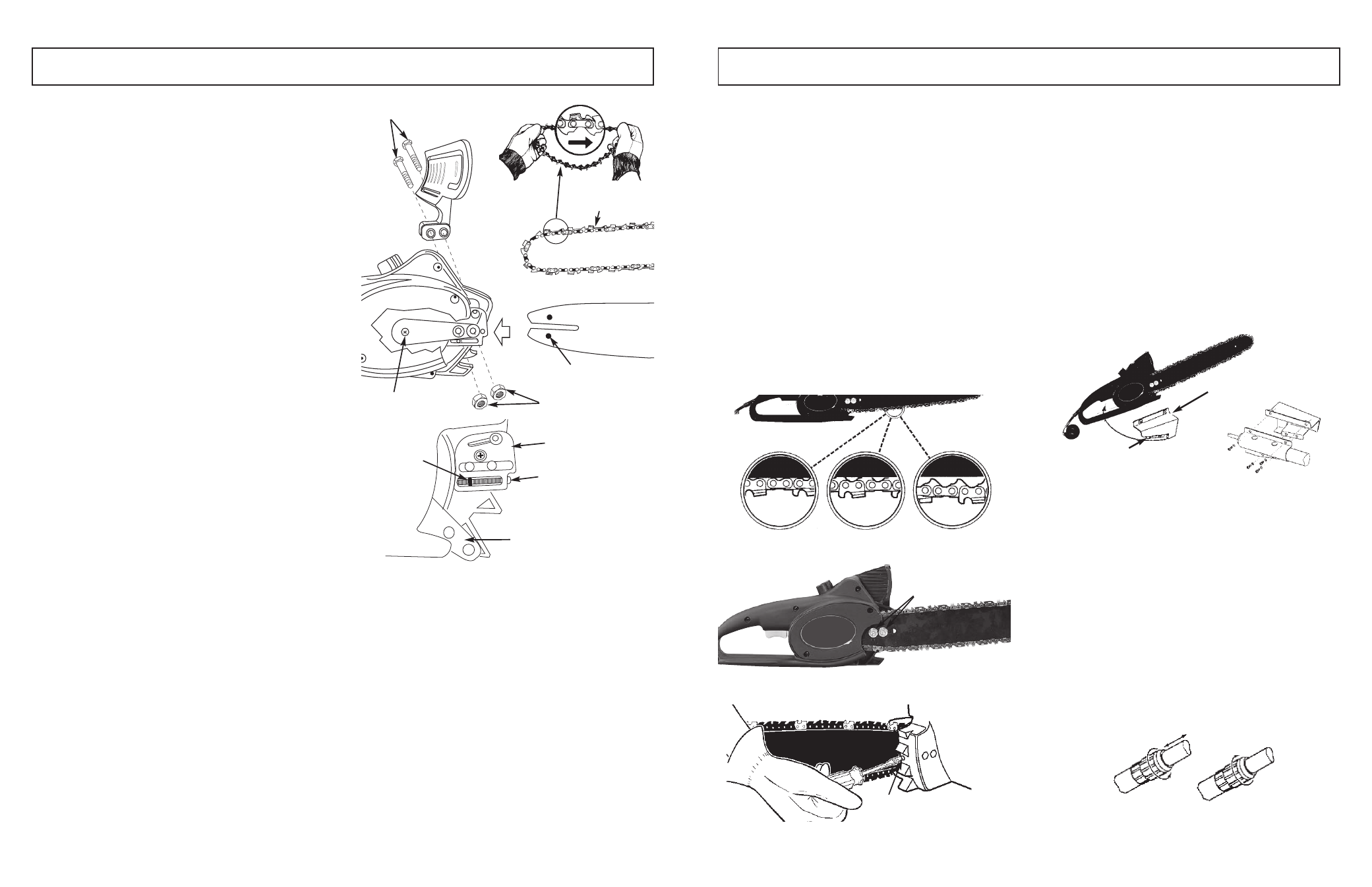

3-6. ASSEMBLY OF POLE SAW

1. Make sure the unit is unplugged from power source.

2. Slip handle bracket (A) over chain saw handle from

the right side (See Fig. 3-6A). NOTE: The trigger must

be depressed before the bracket will go onto the han-

dle. Push the lock-off button and depress the trigger.

While holding the trigger in, place the trigger support

portion of the bracket under the trigger and slide the

bracket onto the chain saw handle. The bracket will

keep the trigger in the “ON” position.

3. Align holes in pole bracket with holes in handle brack-

et. Install Phillips head screws with lock washers

through pole bracket from left side and thread into the

weld nuts on the handle bracket. Tighten screws

securely.

4. Plug the saw power cord into receptacle cord at end

of inner pole.

3-7. ADJUSTING POLE LENGTH

The pole saw has a telescoping pole assembly that will

extend from 57 inches (fully retracted) to 96 inches (fully

extended). A threaded compression coupling is used to

hold the pole in position at any extended length.

1. To extend the pole, loosen coupling by turning cou-

pling nut counterclockwise as shown in Fig. 3-7A. Pole

will slide freely.

2. Pull inner pole section out to desired length of exten-

sion. Note: Only extend pole to minimum length

required to reach limb that is being cut.

3. To lock pole in position, tighten coupling by turning

coupling nut clockwise (See Fig. 3-7A) until firmly

hand tight. Make sure saw handle is aligned with pole

handle before tightening coupling nut.

IMPORTANT: Do not use wrench or pliers to over-

tighten coupling. Damage to coupling or pole may

result.

10

11

3 - ASSEMBLY INSTRUCTIONS

3-5A

3-1. INTRODUCTION

This unit is designed for occasional homeowner use and

should not be used for commercial purposes or subjected

to heavy continuous use.

Your new chain saw can be used for a variety of projects

such as cutting firewood, making fence posts, felling small

trees, limbing, pruning at ground level, and light carpentry.

Cut only wood or wood products with your saw.

3-2. UNPACKING

1. Remove all items from carton.

2. Check all items for any shipping damage. If you find

any damage or if any parts are missing, promptly

inform dealer where you bought the pole saw.

3-3. ASSEMBLY REQUIREMENTS

Your new pole saw will require adjustment of chain and fill-

ing the oil tank with lubricating oil before the unit is ready

for operation. Do not start the saw motor until the unit is

properly prepared.

Read all instructions carefully. Do not install any other size

bar and chain than what is recommended for your model.

3-4. GUIDE BAR / SAW CHAIN

REPLACEMENT INSTALLATION

WARNING

Whenever handling the saw chain, wear work gloves for

protection against sharp cutting edges.

1. Remove bar nuts, push bar bolts in and slide sprock-

et support down. (See Fig. 3-4A)

2. Remove old guide bar and chain.

3. Using a straight screwdriver, turn the chain adjust-

ment screw counterclockwise as far as it will go, or

until tang is to the end of its travel.

4. Loop saw chain over drive sprocket with the cutting

edges of the chain pointing in the direction of rotation.

5. Place the slotted end of guide bar over the bar bolt so

the tang fits into the lower hole in the guide guide bar.

6. Make sure the chain follows the slot in the guide bar.

Slide the sprocket support up and push the bar bolts

through the sprocket support.

7. Install the bar retaining nuts hand tight, (Proceed to

saw chain tension Adjustment).

3-5. SAW CHAIN TENSION ADJUSTMENT

Proper tension of the saw chain is extremely important and

must be checked before starting, as well as during, any cut-

ting operation. Taking the time to make needed adjust-

ments to the saw chain will result in improved cutting per-

formance and prolonged chain life.

NOTE: A new chain and bar will need readjustment after as

few as 5 cuts.This is normal during the break-in period, and

the interval between future adjustments will lengthen quick-

ly (Figure 3-5A).

CAUTION

If a chain is TOO LOOSE or TOO TIGHT, the bar chain and

saw bearings will wear more rapidly. Study Figure 3-5A for

information concerning correct cold tension (A), correct

warm tension (B), and as a guide for when saw chain

needs adjustment (C).

3 - ASSEMBLY INSTRUCTIONS

3-4A

Guide Bar Bolts

Saw Chain

Adjusting Plate

Drive Sprocket

Guide Bar Nuts

Guide Bar

Tang

Adjusting Screw

Sprocket Support

3-5B

D

A

B

C

3-5C

E

3-6A

A

B

3-7A

UNLOCK

LOCK

Adjusting Hole