Step 3, leveling, Step 4, connect power, Step 5, slide product into cutout – GE r10279v User Manual

Page 6: Step 6, install nameplate, Step 7, set temperature controls, Custom frame panel models, Step 3, leveling step 4, connect power, Installation instructions, Step 3 level, Step 5 slide product into the cutout

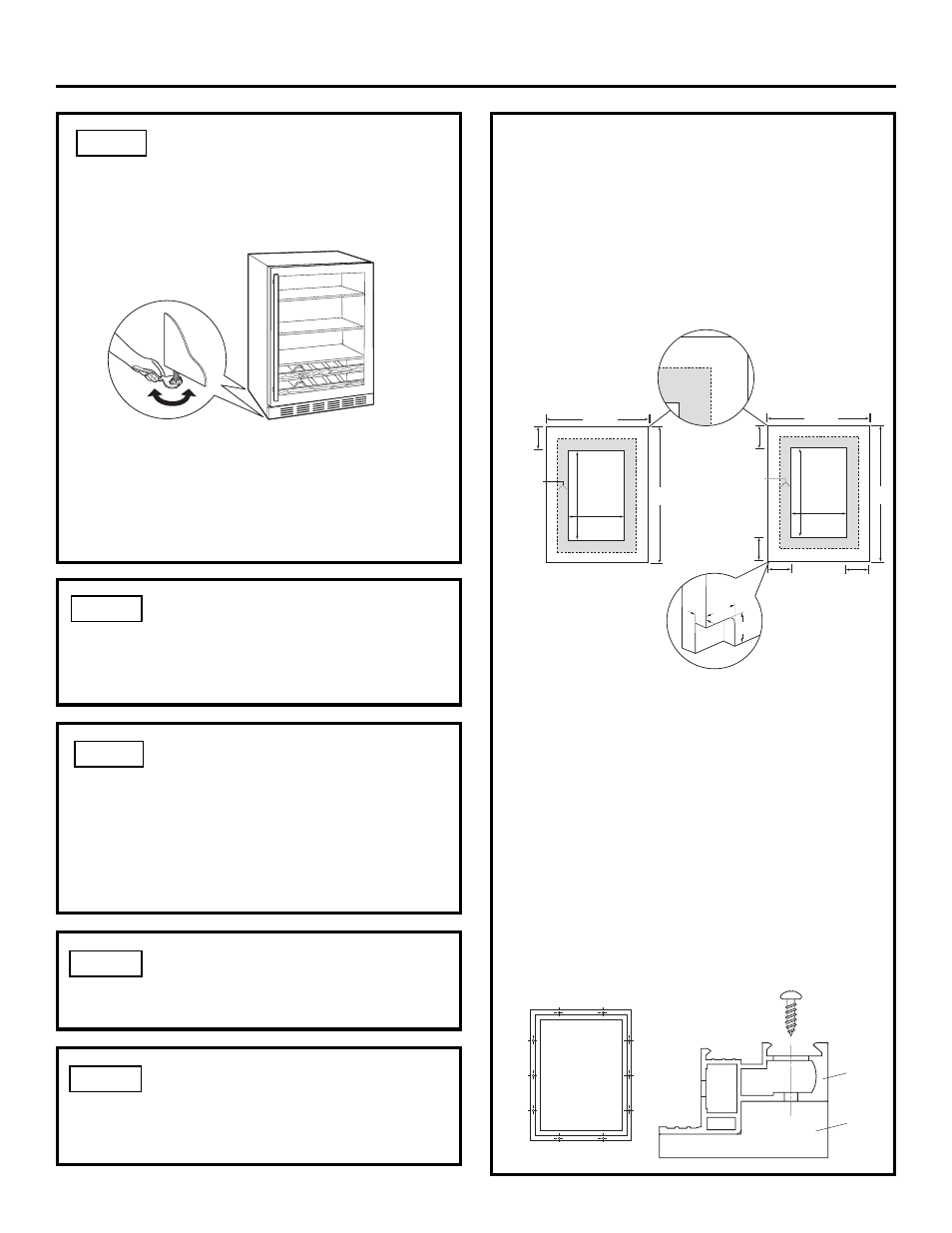

23-1/8”

30”

GLASS

25-1/4”

18-5/8”

2-1/4”

Rout the back

side of the

opening 7/16”

deep, 1-1/8” wide

Cut the notch

1/8” deep, 1/4”

wide and 1/4”

high

2-1/4”

1/8”

1/4”

1/4”

2-1/4”

2-1/2” at

bottom

23-1/8”

29-3/4”

GLASS

25-1/4”

3/4” Thick Custom Panel,

Back Side

18-5/8”

2-1/4”

wide,

all sides

Rout the

back side

of the

opening

7/16”deep,

1-1/8” wide

6

STEP 3 LEVEL

• Use an adjustable wrench to turn the leveling legs and

raise or lower the product.

• Adjust carefully; the product should be level and plumb

with cabinetry, and should align with adjacent toekick

height.

STEP 5 SLIDE PRODUCT INTO

THE CUTOUT

•

Carefully, slide the unit into the opening. Be careful

not to entangle the power cord.

•

Make certain that the door protrudes 1

″ beyond

the surrounding cabinets (1-7/8

″ for custom frame

models).

• Check again to be sure the unit is level.

STEP 4 CONNECT POWER

• Connect power cord plug to a properly grounded

receptacle.

• Check to make sure power is on by opening the door

to see if interior light turns on.

STEP 6 INSTALL NAMEPLATE

• Follow instructions on the back page for installation of

the Monogram nameplate.

STEP 7 SET TEMPERATURE CONTROLS

• The temperature controls are preset. Refer to the

Owner’s Manual for more information. Allow 24 hours

for temperature to stabilize.

Turn Right to Lower

Turn Left to Raise

If you skipped Step 2:

• Select the hinge cover marked “R” or “L”, depending

on door swing.

• Peel backing off the tape inside the decorative

hinge cover. Press and snap into position.

• Snap the screw hole cover into place on the

opposite side.

Installation Instructions

CUSTOM FRAME PANEL MODELS

Model ZDWI240WII and ZDBI240WII

These models require a custom panel frame surrounding

the glass. There are two options: the panel may be 29-3/4

″

or 30

″ high. A 30″ panel requires a notch cut into the bottom

of the panel to avoid interference with the hinges.

• Rout the back side of the panel to the dimensions shown.

• A custom handle of your choice or ZTBSS1 Tubular Handle

must be installed before the panel is mounted onto

the door.

NOTE: A solid panel that covers the door glass CANNOT be

installed on these models.

Install the custom panel:

• Open the door fully.

• Remove the gasket surrounding the inside of the door to

expose the existing screw holes for the custom panel.

• Hold the custom frame panel against the door and align

carefully, top to bottom and side to side. Mark screw hole

locations on the back side of the panel.

• Drill pilot holes in the back side of the custom panel. In

hardwood, drill 3/32

″ pilot holes. In softwood, drill 5/64″ holes.

• Secure the prepared panel to the door using ten (10)

#8 x 5/8

″ screws. Drive the screws through the door frame

and into the wood.

• Replace the gasket.

#8 x 5/8"

Screws

Option 1

Option 2

NOTE: Right-hand models

illustrated. Cut notches

for hinge clearance on the

opposite side for left-hand

door swing.

Choose Option 1 or Option 2 panel size depending on

cabinetry size or style.

GLASS

Back

Custom

Framed

Panel

Door

Frame

NOTE: The 4 corners

of the routed areas

must be squared

to fit the corners

of the metal

door frame.