Generac Power Systems 009600-5 User Manual

Page 31

Generac

®

Power Systems, Inc. 29

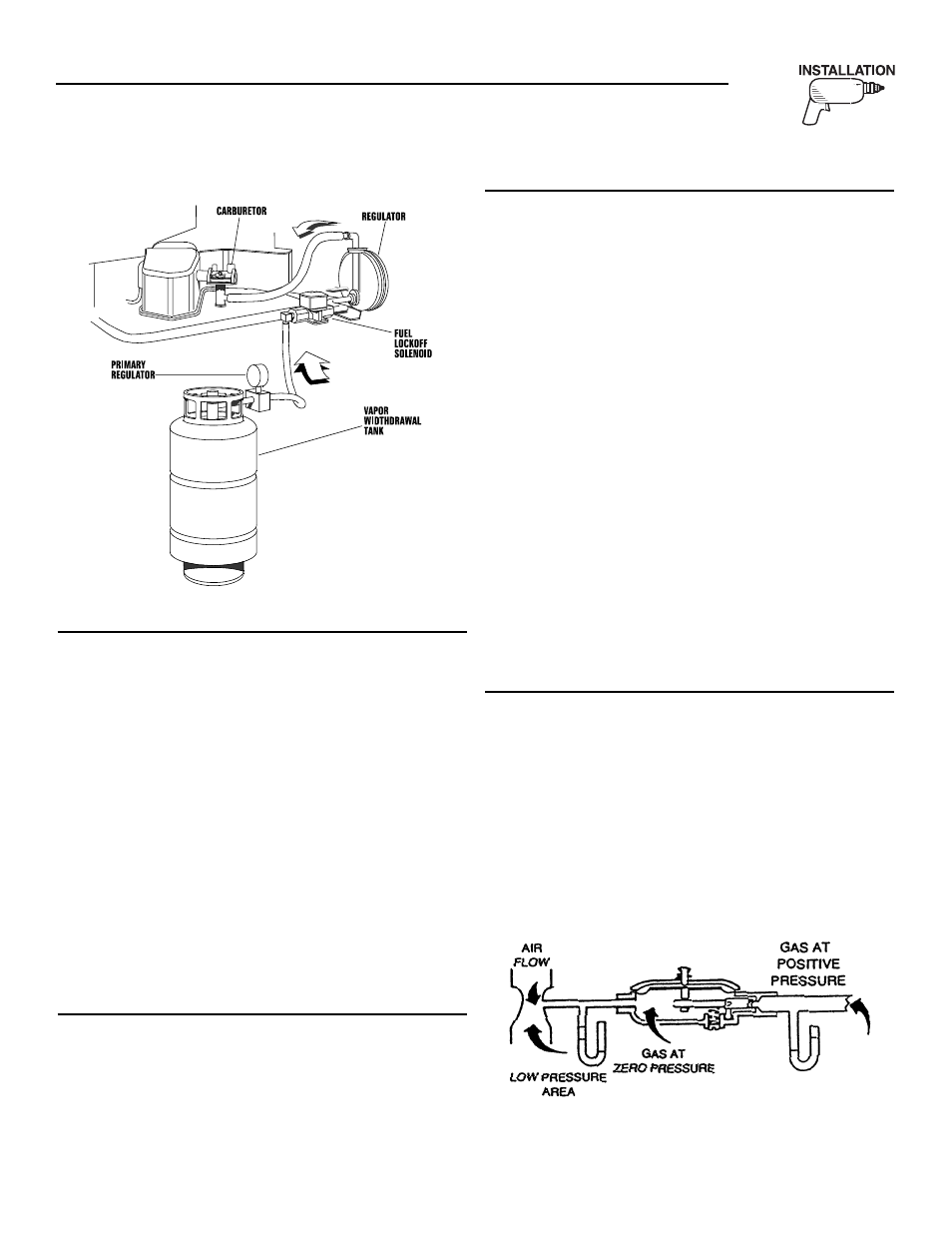

Figure 6.15 – Typical Propane Gas Fuel System

6.5.2 SOME IMPORTANT CONSIDERATIONS

When installing an LP gas system, consider seriously

the following items:

• All fittings, lines, hoses and clamps must be tight and

free of leaks. Apply a pipe sealant to threads when

assembling threaded connections. This reduces the

possibility of leakage.

• Test the entire fuel system for leaks using approved

test methods.

• Optimum gas pressure at the inlet to the gaseous fuel

solenoid valve and secondary regulator is 11 inches

water column.

• The installer’s fuel supply connection point is at the

gaseous fuel solenoid valve. This is a 3/4-inch

(female) connection. Provide a suitable 3/4-inch NPT

(male) connector to attach to the fuel supply line.

• Use a length of approved flexible fuel hose between

the gaseous fuel solenoid valve and rigid gas piping.

The flexible line should be at least 6 inches longer

than necessary.

6.5.3 VAPOR WITHDRAWAL

LP gas is stored in pressure tanks as a liquid. The gas

systems used with these generators were designed only

for vapor withdrawal type systems. Vapor withdrawal

systems use the gas vapors that form above the liquid

fuel in the tank. Do NOT attempt to use the generator

with any liquid withdrawal type system.

6.5.4 PRIMARY REGULATOR

Gas pressure delivered to the solenoid valve must be

properly regulated by means of a primary gas regulator.

Mount the primary regulator at the gas tank outlet or in

the supply line from the gas tank. The following rules

apply:

• For best results, the primary regulator supplies

gaseous fuel to the secondary regulator at 11 inches

water column. Do NOT exceed 14 inches water col-

umn.

• The installer must be sure the primary regulator is

rated at sufficient gas flow to operate the generator

plus all other gas appliances in the circuit.

NOTE:

Recommended MINIMUM gas flow rate for all air-

cooled PRIMEPACT series generators is 67 cubic feet

per hour.

If an existing primary gas regulator does not have a

sufficient flow capacity for the generator and other

gas appliances in the circuit, (a) install a primary

regulator with adequate flow rate, or (b) install a sep-

arate regulator only and rated at least 67 cubic feet

per hour. The inlet side of any primary regulator that

supplies the generator must connect directly to a gas

pressure tank. Do NOT tee the generator line into a

gas circuit feeding other areas.

6.5.5 GASEOUS CARBURETION

LP gas vapors should be supplied to the secondary reg-

ulator inlet at about 11 inches water column (positive

pressure). The engine pistons draw air in during the

intake stroke (Figure 6.16). This air passes through a

carburetor venturi, which creates a low pressure that is

proportional to the quantity of air being pumped. The

low pressure from the carburetor venturi acts on the

regulator diaphragm to pull the diaphragm toward the

source of low pressure. A lever attached to the

diaphragm opens a valve to permit gas glow through the

carburetor.

Figure 6.16 – LP Gas Carburetion Diagram

◆

◆

◆

◆

Section 6 – Installation

PRIMEPACT 66G and 66LP Recreational Vehicle Generators