Shipping bracket workstop – Grizzly G9744Z User Manual

Page 19

G9744Z Metal Cutting Bandsaw

-17-

Shipping Bracket

Workstop

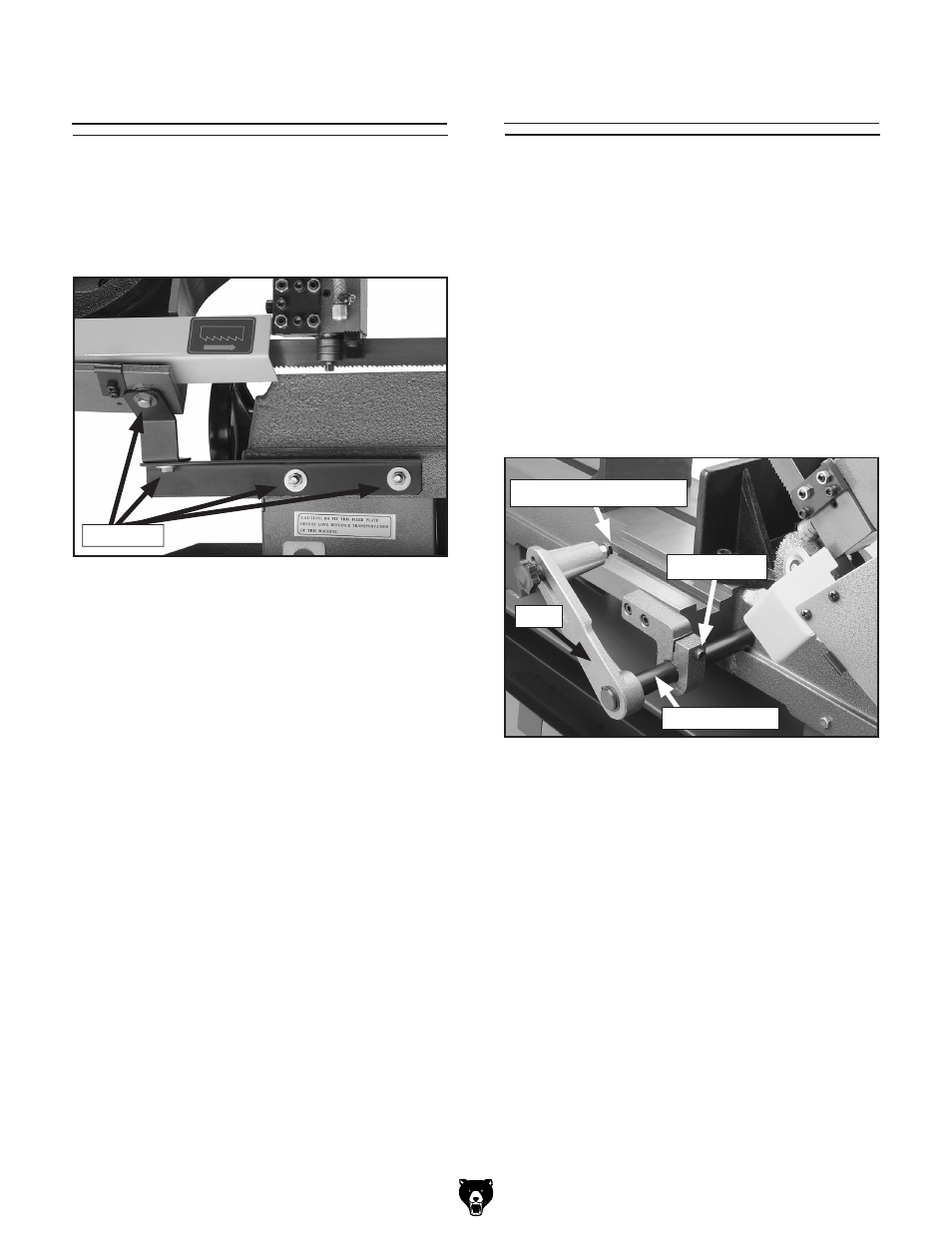

Figure 8. Shipping bracket.

A bracket has been installed to keep the saw in

alignment during shipping. Before using your saw

you will need to remove it. Store it for safe keep-

ing in the event you move your saw to a different

location.

To remove the shipping bracket:

1. Remove all four hex bolts shown in Figure 8

with a 12mm wrench.

The workstop is used when many cuts of the

same length are needed (see

Figure 9).

To setup the workstop:

1. Position the workstop rod the desired dis-

tance from the blade and tighten the cap

screw to hold it in place.

2. Fine tune the measurement by adjusting the

hex bolt and stop nut.

3. Swing the workstop arm down and out of the

way when not in use.

Figure 9. Workstop assembly.

Workstop Rod

Hex Bolt & Stop Nut

Arm

Cap Screw

Hex Bolts

- G0506 (56 pages)

- 12" Cold Cut Saw G0682 (52 pages)

- G1127 (3 pages)

- 24" & 27" Resaw Bandsaws G3619 (56 pages)

- H7197 (1 page)

- INDUSTRIAL BANDSAW W/FOOT BRAKE G0513X2F (108 pages)

- Heavy-Duty Table G1023Z (63 pages)

- G0641 (56 pages)

- Air Cut-Off G8122 (2 pages)

- Ultimate 14" Bandsaw G0555 (68 pages)

- G4186Z (48 pages)

- H8145 (36 pages)

- G0691 (11 pages)

- G0691 (92 pages)

- G0592 (60 pages)

- Model G1022proz (84 pages)

- G0605X1-6X1 (12 pages)

- Model G1023zx3 (63 pages)

- G1016 (30 pages)

- H0604 (10 pages)

- ZX (63 pages)

- g0531b (8 pages)

- G3620 (56 pages)

- G1023SL (50 pages)

- G1023SLWX (3 pages)

- 50/65 Ton Ironworker G0647 (76 pages)

- Zero Clearance Table Insert H7396 (1 page)

- H7583 (28 pages)

- G0621 (60 pages)

- G0457 (64 pages)

- G0605X1 (101 pages)

- H0629 (3 pages)

- Slow Speed Cold Cut G0665 (40 pages)

- G0717 (60 pages)

- G0659 (60 pages)

- G0606X1 (12 pages)

- G0605X/G0606X (76 pages)

- G5787 (37 pages)

- G8599 (13 pages)

- T10131 (4 pages)

- G0513P (108 pages)

- G9906 (14 pages)

- G0513X2 (108 pages)

- G7211 (34 pages)

- G1052 (34 pages)