Blade changes, Blade break-in – Grizzly 12" Cold Cut Saw G0682 User Manual

Page 29

g0682 12" Cold Cut saw (mfg. since 12/10)

-27-

blade Changes

The teeth of saw blades

are sharp and can easily

cut fingers and hands.

Always wear heavy leath-

er gloves when handling

saw blades.

Tools Needed:

Qty

hex Wrenches 5, 10mm ..............................1 ea.

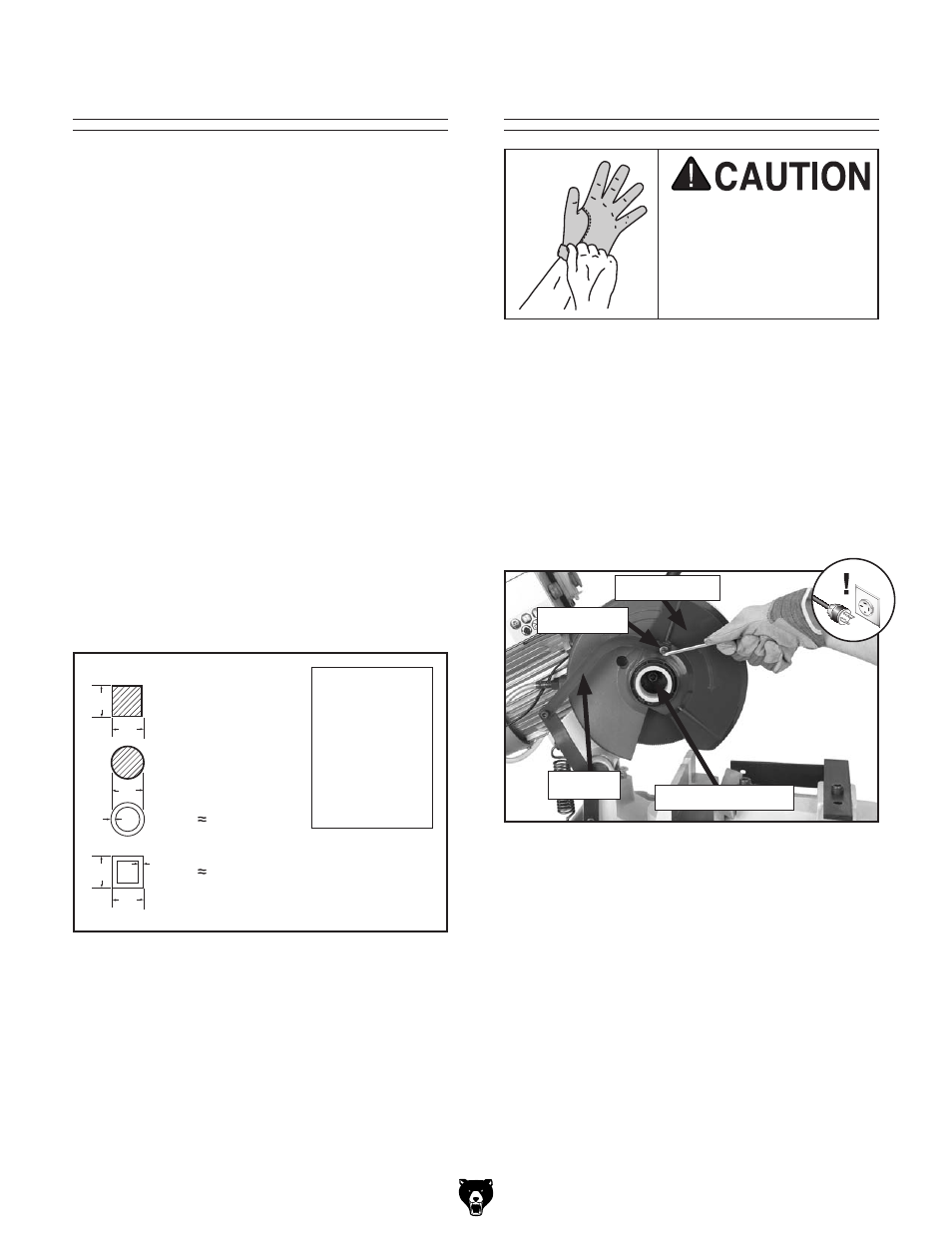

To replace the blade:

1. disCoNNeCt saW From poWer!

2. disconnect the blade guard linkage by remov-

ing the cap screw that connects it to the saw

guard (

figure 42).

figure 42. removing guard linkage.

Cap screw

blade guard

linkage

arbor Cap screw

blade break-in

proper break-in is important for the cutting per-

formance and longevity of the blade. during the

break-in period, only mild pressure should be

exerted on the blade (about half of the normal

feed pressure for a properly broken-in blade).

the duration of the break-in period is determined

by the hardness of the material cut. the break-

in period is defined in terms of square inches of

material cut.

—For hard materials, such as steel, the

break-in period is the first 50 square inches

of material cut.

—For soft materials, such as aluminum,

the break-in period is the first 150 square

inches of material cut.

to determine the square inches of a cut, calculate

the area of the cross-section of the workpiece.

Keep in mind when cutting hollow-section pieces

that the area only includes the solid walls of

the workpiece. refer to

figure 41 to calculate

approximate square inches for many typical cuts.

D

L

H

L

Th

Th

H

A = L x H

A = (

D

⁄

2

)² x

π

A =Area

H =Height

L =Length

D =Diameter

Th =Material

Thickness

π =3.14

A D x

π x Th

A 2H + 2L x Th

figure 41.

Calculating cut area for break-in.