Troubleshooting – Grizzly G9003 User Manual

Page 16

G9003 Portable Planer

-16

-

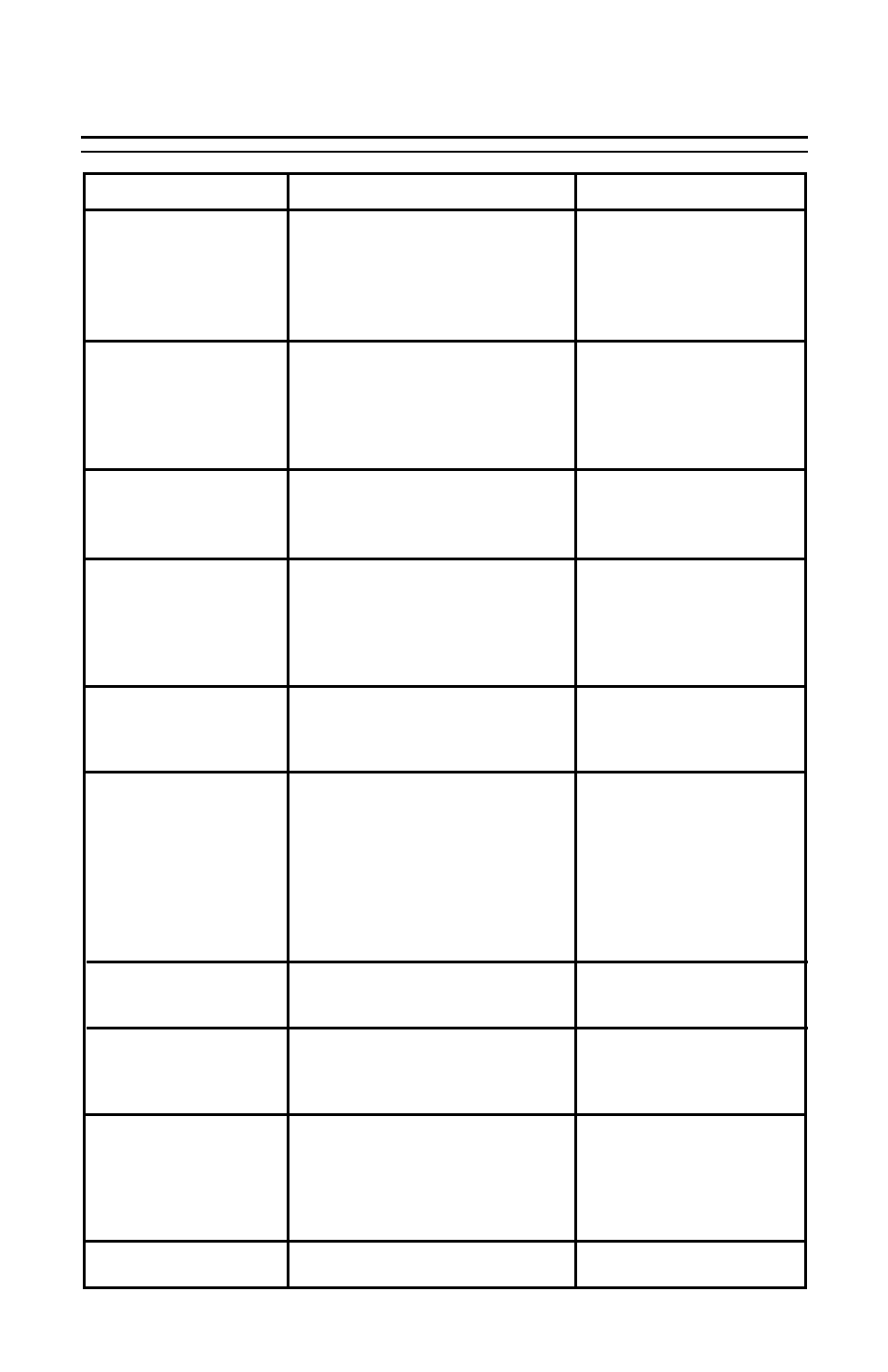

TROUBLESHOOTING

SYMPTOM

Motor will not start.

Motor will not start;

fuses or circuit breakers

blow.

Motor overheats.

Motor arcing visibly

through vents or runs

erratically.

Machine slows when

operating.

Machine is loud when

cutting. Overheats or

bogs down in the cut.

Planer starts, but cutter-

head does not move.

Planer starts, cutter-

head turns, no cut.

Rough or fuzzy cut.

Cut not smooth or straight.

POSSIBLE CAUSE

1. Low voltage.

2. Brushes worn or sticking.

3. Open circuit in motor or loose

connections.

1. Short circuit in line cord or

plug.

2. Short circuit in motor or loose

connections.

1. Motor overloaded.

2. Air circulation through the

motor restricted.

1. Brushes sticking.

2. Brushes worn.

1. Feed rate too high.

2. Depth of cut too great.

3. Brushes worn.

1. Excessive depth of cut.

2. Blades are dull

3. Blade holder or blade assem-

bly mounting is loose.

4. Belt is worn or loose.

5. Short circuit in motor.

Worn or broken belt

1. Blade not extending below

foot.

2. Belt worn or slipping.

1. Blades are dull.

2. Excessive depth of cut.

3. Cutting against natural wood

grain.

4. High wood moisture content.

Blade not flush with rear foot.

CORRECTIVE ACTION

1. Check power line for

proper voltage.

2. Replace both brushes.

3. Inspect by qualified

electrical technician.

1. Inspect cord or plug for

damaged insulation

and shorted wires.

2. Inspect by qualified

electrical technician.

1. Reduce load on motor.

2. Clean out motor vents

1. Check that brush hold-

er is free of dirt and

that brush moves

freely.

2. Replace both brushes.

1. Feed planer slower.

2. Reduce depth of cut.

3. Replace both brushes.

1. Decrease depth of cut.

2. Sharpen blades.

3. Recheck complete

blade installation and

tighten all screws.

4. Replace belt.

5. Inspect by qualified

electrical technician.

Replace belt

1. Increase depth of cut.

2. Replace belt.

1. Sharpen blades.

2. Decrease depth of cut.

3. Reverse cutting direc-

tion.

4. Dry wood.

Reset blades in jig.