GE QS1800V User Manual

Page 25

19

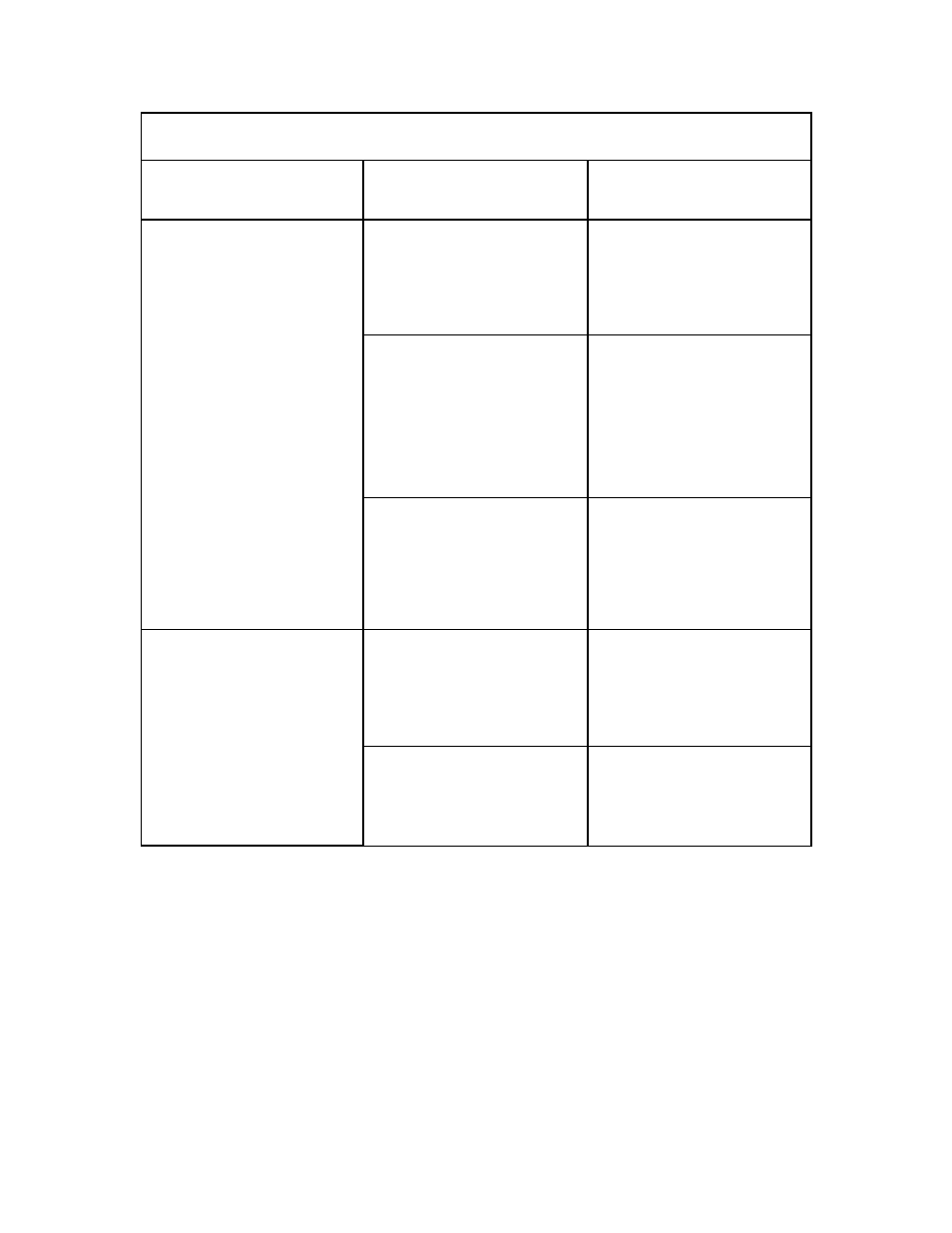

REMEDIES

Confirm both the pump liquid

end and motor module are

firmly secured to a rigid

structure.

QSV pumps must be fed with

positive pressure [at least

20 psi (1.4 bar). Check to

make sure there are no

obstructions, constrictions,

high points, or clogged filters

ahead of the pump.

QSV pumps must operate in

the flow range specified by

the performance summary

table or the pump perform-

ance curve.

Seal threaded fittings with

Teflon tape. Make sure gas-

kets are properly seated in

Victaulic or flanged fittings.

Replace the O-ring if possible,

or return the pump to the

factory for repair.

POSSIBLE CAUSES

Improper mounting

Starved suction line

Operating off the

performance curve

Piping not properly sealed

O-rings in pump casing or

motor module damaged

PROBLEM

Pump/motor vibrates

Pump leaks

T R O U B L E S H O O T I N G G U I D E