Service transmission – Great Dane GSRKA1934S User Manual

Page 25

SERVICE TRANSMISSION

SERVICE TRANSMISSION- 23

Service Transmission

Hydraulic Oil

Use only 5W-50 or 15W-50 all synthetic oil.

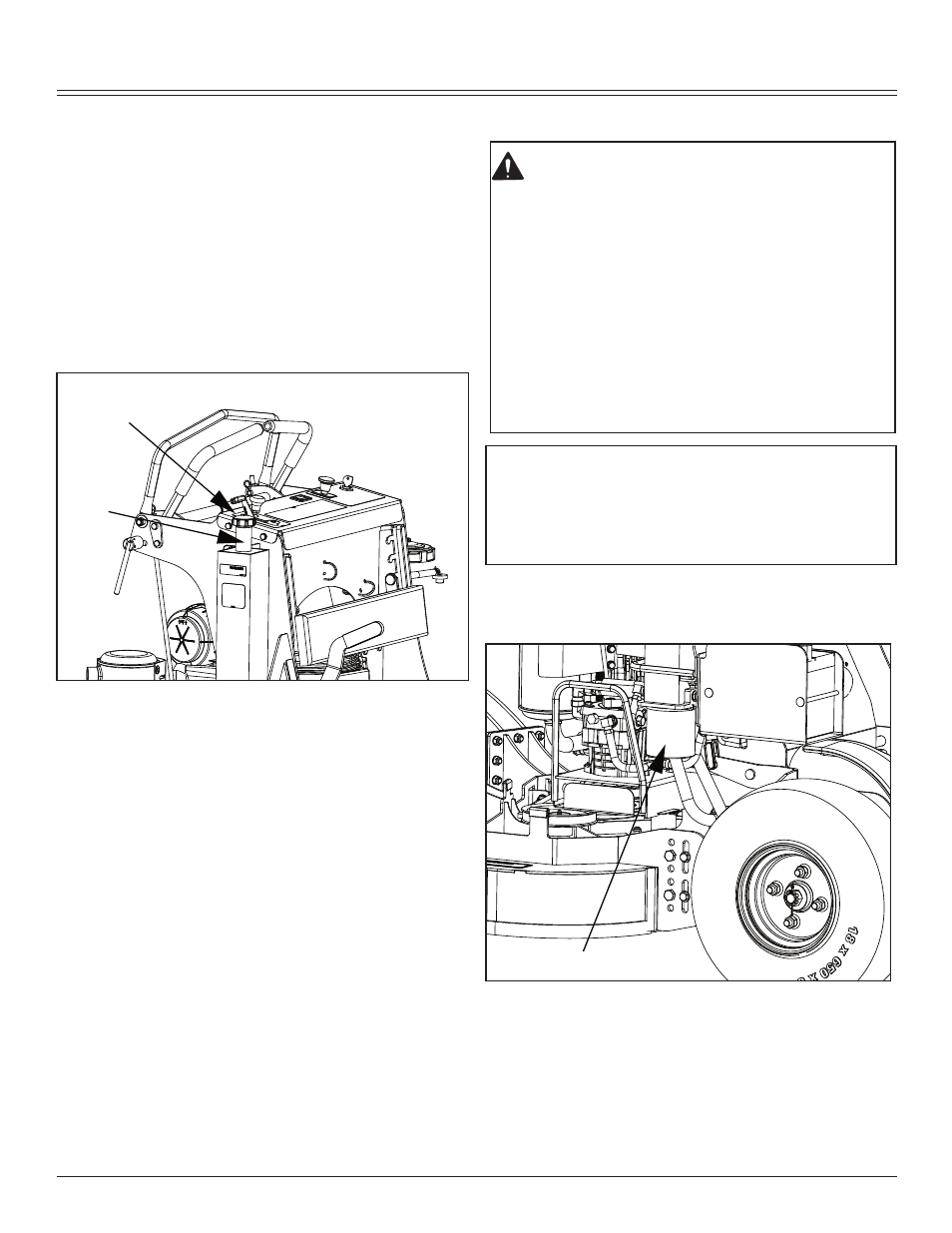

Checking Hydraulic Oil Level

IMPORTANT: Avoid Damage! Check oil level in reser-

voir tank when oil is cold.

Do not overfill oil reservoir tank. Oil will expand during oper-

ation and could overflow.

Park machine safely. (Refer to Parking Safely in

SAFETY section.)

B

A

Clean area around reservoir dipstick cap (B).

Remove dipstick cap (A). Wipe dipstick clean.

NOTE: Do not tighten dipstick cap when checking oil

level.

Insert dipstick into reservoir filler neck (B). Do not

tighten cap.

Remove dipstick. Check oil level on dipstick. Oil level

should be in crosshatch area between ADD and FULL

marks.

If oil is low, add oil to bring oil level no higher than

FULL mark on dipstick.

If oil is above FULL mark, drain oil to proper level.

Insert dipstick. Tighten cap.

1.

2.

3.

4.

5.

•

•

6.

Changing Hydraulic Oil and Filter

CAUTION: Avoid injury! Escaping fluid under

pressure can penetrate the skin causing

serious injury. Avoid the hazard by relieving

pressure before disconnecting hydraulic or

other lines. Tighten all connections before

applying pressure. Search for leaks with a

piece of cardboard. Protect hands and body

from high pressure fluids.

Use caution when filling and draining

hydraulic oil. During periods of machine

operation the hydraulic oil reservoir can get

hot. Allow engine and oil reservoir to cool

before servicing.

IMPORTANT: Avoid Damage! Contamination of hydrau-

lic fluid could cause transmission damage or failure.

Do not open oil reservoir cap unless absolutely neces-

sary.

Severe or unusual conditions may require a more fre-

quent service interval.

Park machine safely. (Refer to Parking Safely in the

SAFETY section.)

Allow engine and hydraulic oil reservoir to cool.

A

Clean area around reservoir dipstick cap and oil filter.

Turn oil filter (A) counterclockwise to remove.

Allow hydraulic oil to drain into a drain pan with a ca-

pacity of at least 3.8L (1.0 gal).

Apply a film of clean hydraulic oil to gasket of new filter.

Install new filter. Turn filter clockwise until gasket

makes contact with mounting surface. Tighten 1/2 to

3/4 turn after gasket contact.

Remove dipstick cap from hydraulic reservoir filler

neck.

1.

2.

3.

4.

5.

6.

7.