Adjusting gibs, Replacing motor brushes & fuse – Grizzly G0463 User Manual

Page 28

-26-

G0463 Small Mill/Drill

Adjusting Gibs

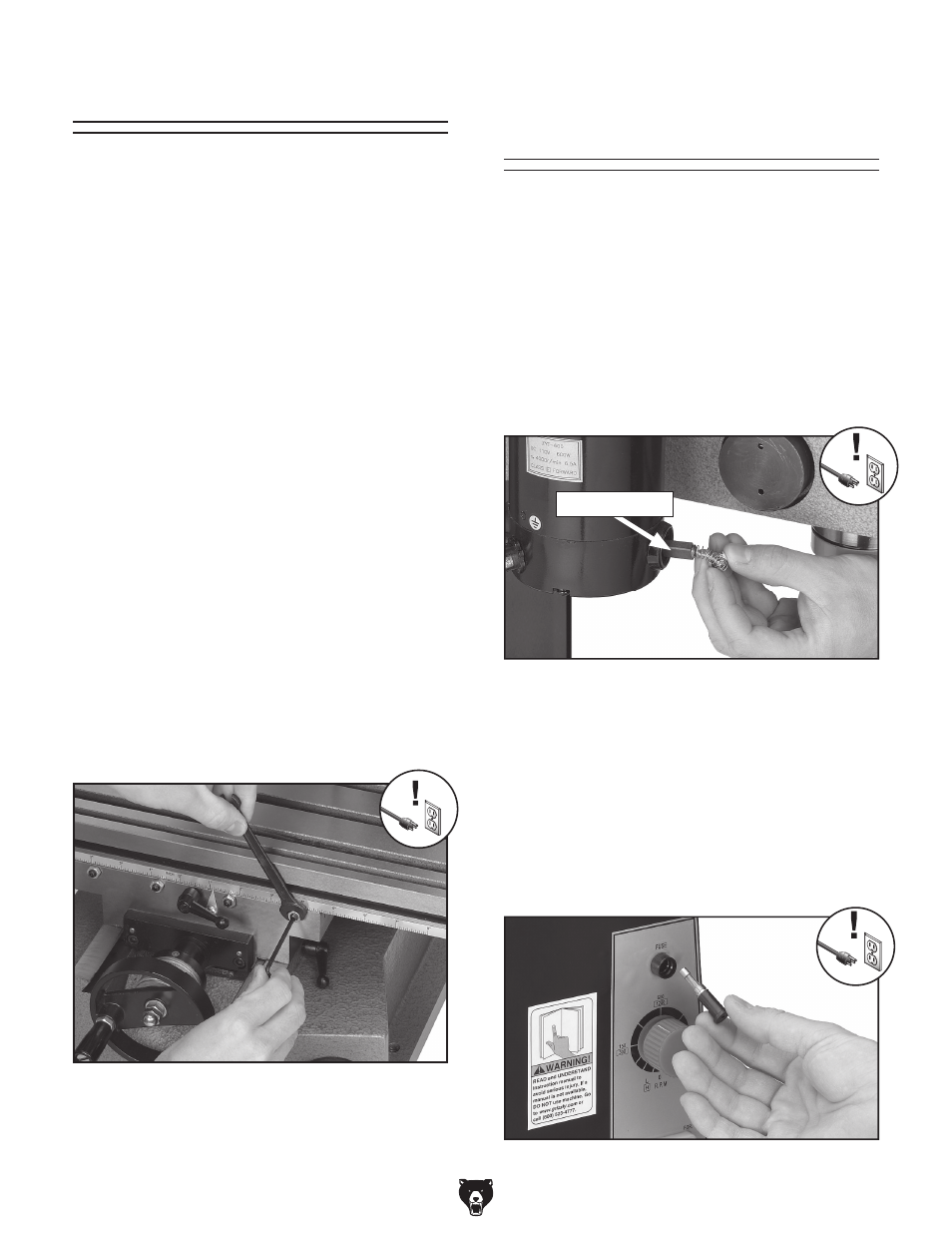

Figure 27. Gib adjustment.

The function of the gibs is to take out play in the

table, and cross slide, and column without causing

the slides to bind. The gibs are pre-adjusted at the

factory and should not need further adjustment

until many hours of machine use. If the movement

seems too tight at first, make sure the locks are

fully released. Next, make sure the bedways are

thoroughly cleaned of rust preventative and lubri-

cated with oil.

Tools Needed:

Qty

Wrench 10mm ................................................... 1

Hex Wrench 3mm .............................................. 1

Each gib has multiple lock nuts and set screws

that need to be adjusted. Make your adjustments

equally and in small increments.

To adjust the gibs: (see Figure 27)

1. UNPLUG THE MILL/DRILL!

2. Loosen the lock nuts.

3. Move the table and slightly tighten each

set screw. When properly adjusted, the gib

should offer slight resistance without bind-

ing.

4. Tighten the lock nuts.

After some period of time, the carbon brushes

on the DC motor will need to be replaced.

Always replace the brushes in pairs. Use part #

P0463242.

To replace the motor brushes:

1. UNPLUG THE MILL/DRILL!

2. Remove and replace the spring and carbon

brush.

Replacing Motor

Brushes & Fuse

Figure 28. Carbon brush removal.

Carbon Brush

A 10 Amp fuse is housed in the body near the

main controls.

To replace the fuse:

1. UNPLUG THE MILL/DRILL!

2. Remove and replace the fuse from the fuse

cradle (see

Figure 29).

Figure 29. Fuse replacement.