Lubrication, Cleaning, Schedule – Grizzly G9742 User Manual

Page 28

-26-

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

Always disconnect power

to the machine before

performing maintenance.

failure to do this may

result in serious person-

al injury.

Lubrication

Cleaning the Model G9742 is relatively easy.

Keeping.metal.chips.away.from.bandsaw.mecha-

nisms. is. important. to. making. sure. that. your.

bandsaw.lasts.a.long.time..Use.a.shop.vacuum.

or.brush.off.metal.chips.frequently..

Cleaning

SECTION 6: MAINTENANCE

Schedule

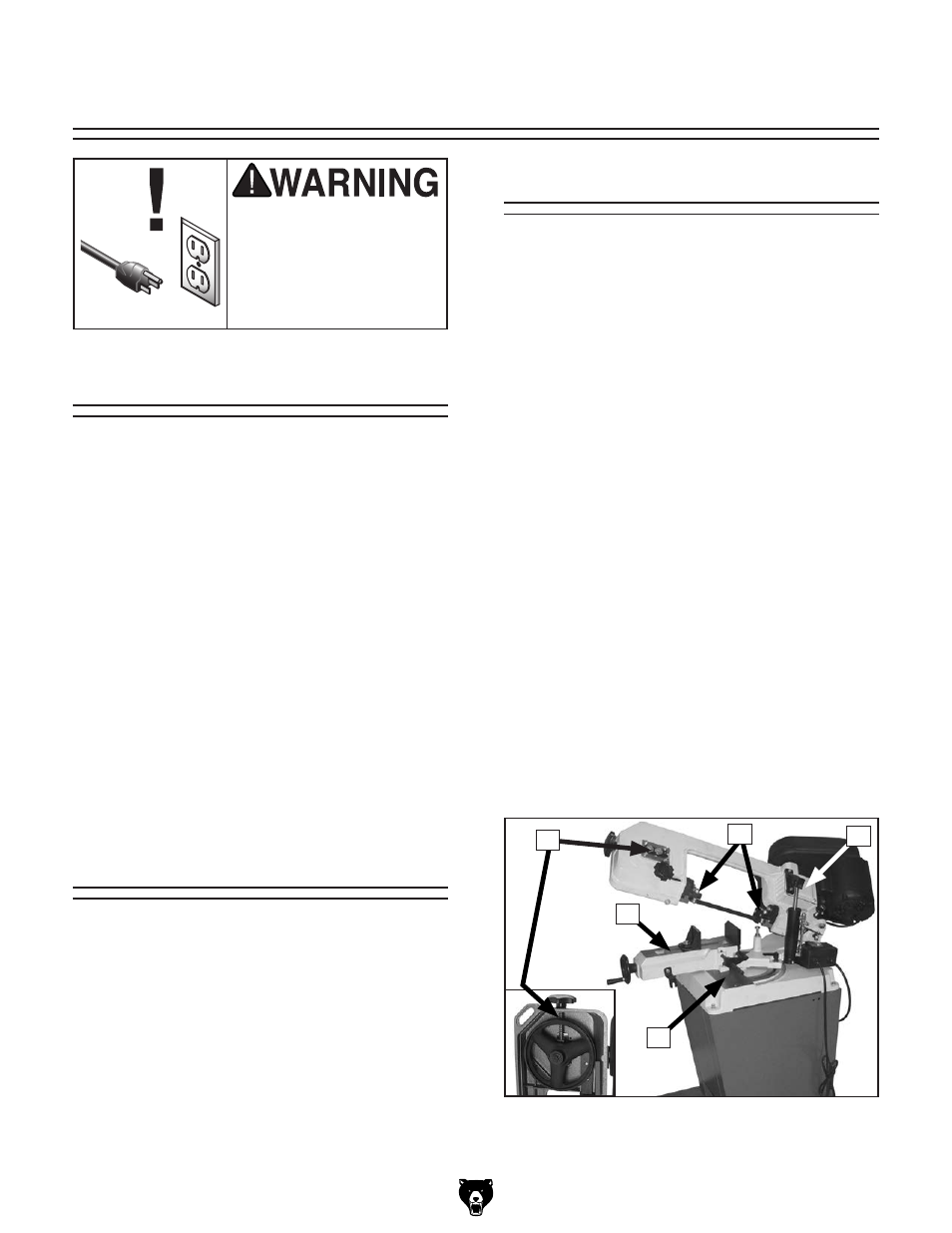

D

C

E

For optimum performance from your machine,

follow this maintenance schedule and refer to any

specific instructions given in this section.

Daily Check

• loose mounting bolts.

• damaged saw blade.

• Worn or damaged wires.

• any other unsafe condition.

• Clean after each use.

• proper blade tension.

Monthly Check

• lubricate vise screw.

• Check V-Belt for wear.

Annual Check

• inspect gear lubrication.

The.gearbox.and.all.bearings.are.sealed.and.per-

manently.lubricated.so.no.scheduled.lubrication.is.

needed..However,.you.must.periodically.lubricate.

adjustment. locations. and. bare. metal. surfaces..

Refer.to.

figure 36.for.lubrication.points.

Lubricate the following areas listed below:

A. Blade Tension Mechanism: Open.the.main.

blade.guard,.and.drop.a.few.drops.of.oil.on.

the.tension.knob.lead.screw.

B. Blade and Guides:

Drop. a. few. drops. of.

light.machine.oil.on.the.blade.and.the.blade.

guides.daily.

C. Gear Box

: Is.packed.with.grease.and.should.

only. be. changed. if. you. suspect. contamina-

tion.has.entered.

D. Table and Machined Surfaces:

Keep. bare.

metal.surfaces.rust-free.with.regular.applica-

tions.of.products.like.SLIPIT®..For.long.term.

storage. you. may. want. to. consider. products.

like.Boeshield.T-9™.

E. Vise Lead Screw:

Drop.a.few.drops.of.light.

machine.oil.on.the.vise.lead.screw.weekly.

figure 36. Lubrication.points.

B

A