Blade selection – Grizzly G9742 User Manual

Page 22

-20-

G9742 Metal Cutting Bandsaw (Mfg. Since 11/06

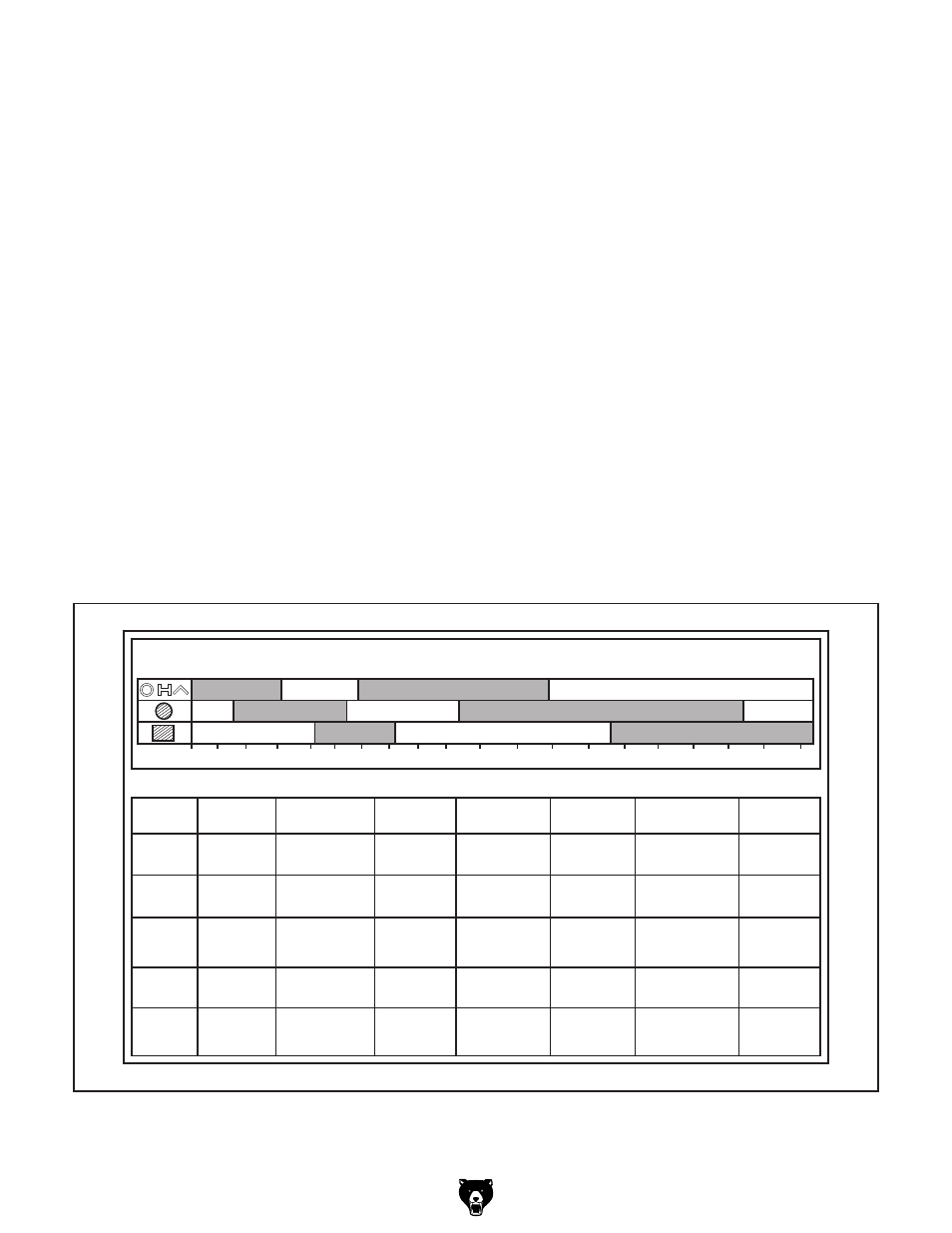

Blade Selection

The.chart.below.is.a.basic.starting.point.for.choos-

ing.blade.type.based.on.teeth.per.inch.(TPI).for.

variable.tooth.pitch.blades.and.for.standard.raker.

type. bimetal. blades/HSS. blades.. However,. for.

exact. specifications. of. bandsaw. blades,. contact.

the.blade.manufacturer.

Here. are. some. general. rules. of. thumb. with.

respect.to.bandsaw.blade.use..

•.

At. least. three. teeth. must. contact. the. metal.

at.any.phase.of.the.cut..Otherwise,.the.teeth.

can. load. up. with. metal,. fracture,. and. break.

off..If.the.TPI.is.too.high,.the.teeth.can.load.

up.with.material.and.overheat,.damaging.the.

blade.

•.

For.a.faster.but.rougher.cut,.use.a.blade.with.

a.lower.TPI.and.a.higher.feed.rate.

•.

For.a.slower.but.smoother.cut,.use.a.blade.

with.more.TPI.and.a.lower.feed.rate.

Copper

Alloy

229~482

(70) (147)

203~213

(62) (65)

85-203

(26) (62)

220

(67)

220~534

(67) (163)

203

(62)

85

(26)

321

(98)

180~220

(54) (67)

95~213

(29) (65)

242

(75)

65~85

(20) (26)

180~220

(54) (67)

75~118

(25) (36)

246

(75)

108~225

(33) (75)

196~354

(60) (108)

203

(62)

111~321

(34) (98)

150~203

(46) (62)

Aluminum

Alloy

Thin

Tube

Angle

Steel

Carbon

Steel

Speed FPM

(M/Min)

Speed FPM

(M/Min)

Speed FPM

(M/Min)

Speed FPM

(M/Min)

Material

TOOTH SELECTION

CUTTING SPEED RATE RECOMMENDATION

Material

Material

Material

Tool Steel

Mold Steel

High-Speed

Tool Steel

Alloy

Steel

Water

Hardened

Tool Steel

Stainless

Steel

CR Stainless

Steel

Free Machining

Stainless Steel

Gray

Cast Iron

Ductile

Austenitic

Cast Iron

Malleable

Cast Iron

Plastics

Cold-Work

Tool Steel

Hot-Work

Tool Steel

Oil-Hardened

Tool Steel

50

2

3

4 5

6

7

8

9

10

11

12

13

14 15

16

17

18

19

2½

3½

75

100

150

200

250

300

350

400

2/3

2/3

2/3

1.4/2.5

1.4/2.5

1.5/.8

1.5/.8

3/4

3/4

3/4

4/6

4/6

5/8

450

mm

inch

figure 21. Blade.selection.chart.

To select the correct blade TpI:

1.. Measure. the. material. thickness.. This. mea-

surement. is. the. length. of. cut. taken. from.

where.the.tooth.enters.the.workpiece,.sweeps.

through,.and.exits.the.workpiece..

2.. Refer.to.the."Material.Thickness".row.of.the.

blade.selection.chart.in

figure 21,.and.read.

across. to. find. the. workpiece. thickness. you.

need.to.cut.

3.. Refer.to.the."Shape".of.metal.and."Material.

Type". columns,. and. find. the. shape. and.

material.to.be.cut..

4.. In.the.applicable.row,.read.across.to.the.right.

and.find.the.box.where.the.row.and.column.

intersect.. Listed. in. the. box. is. the. minimum.

TPI.recommended.for.the.variable.tooth.pitch.

blades,.and.the.TPI.for.bimetal.raker.blades.

in.parentheses..