Installation of direct gas piping, Determine the supply gas requirements, Install additional regulator if required – Greenheck Fan Make-Up Air Unit VSU User Manual

Page 6: Connect the supply gas line

6

Model VSU Make-Up Air

®

®

®

®

®

Installation of Direct Gas Piping

IMPORTANT

All gas piping must be installed in accordance

with the latest edition of the National Fuel Gas

Code ANSI/Z223.1 and any local codes that may

apply. In Canada, the equipment shall be installed

in accordance with the Installation Code for Gas

Burning Appliances and Equipment (CGA B149)

and Provincial Regulations for the class. Authorities

having jurisdiction should be consulted before

installations are made.

WARNING

All components of this or any other gas-fired heating

unit must be leak tested prior to placing the unit

into operation. A soap and water solution should be

used to perform this test. NEVER test for gas leaks

with an open flame.

WARNING

If pressure testing in excess of 1/2 psig (3.5 kPa),

the heater and manual shutoff valve must be

disconnected from the supply gas line.

WARNING

If pressure testing at or below 1/2 psig (3.5 kPa), the

heater must be isolated from the supply gas line by

closing its manual shutoff valve.

IMPORTANT

All piping should be clean and free of any foreign

matter. Foreign material entering the gas train can

damage the valves, regulators and burner.

IMPORTANT

Do NOT connect the unit to gas types other than

what is specified and do NOT connect the unit to

gas pressures that are outside of the pressure range

shown on the label.

NOTE

When connecting the gas supply, the length of the

run must be considered in determining the pipe size

to avoid excessive pressure drop. Refer to a Gas

Engineer’s Handbook for gas pipe capacities.

1. Determine the Supply Gas

Requirements

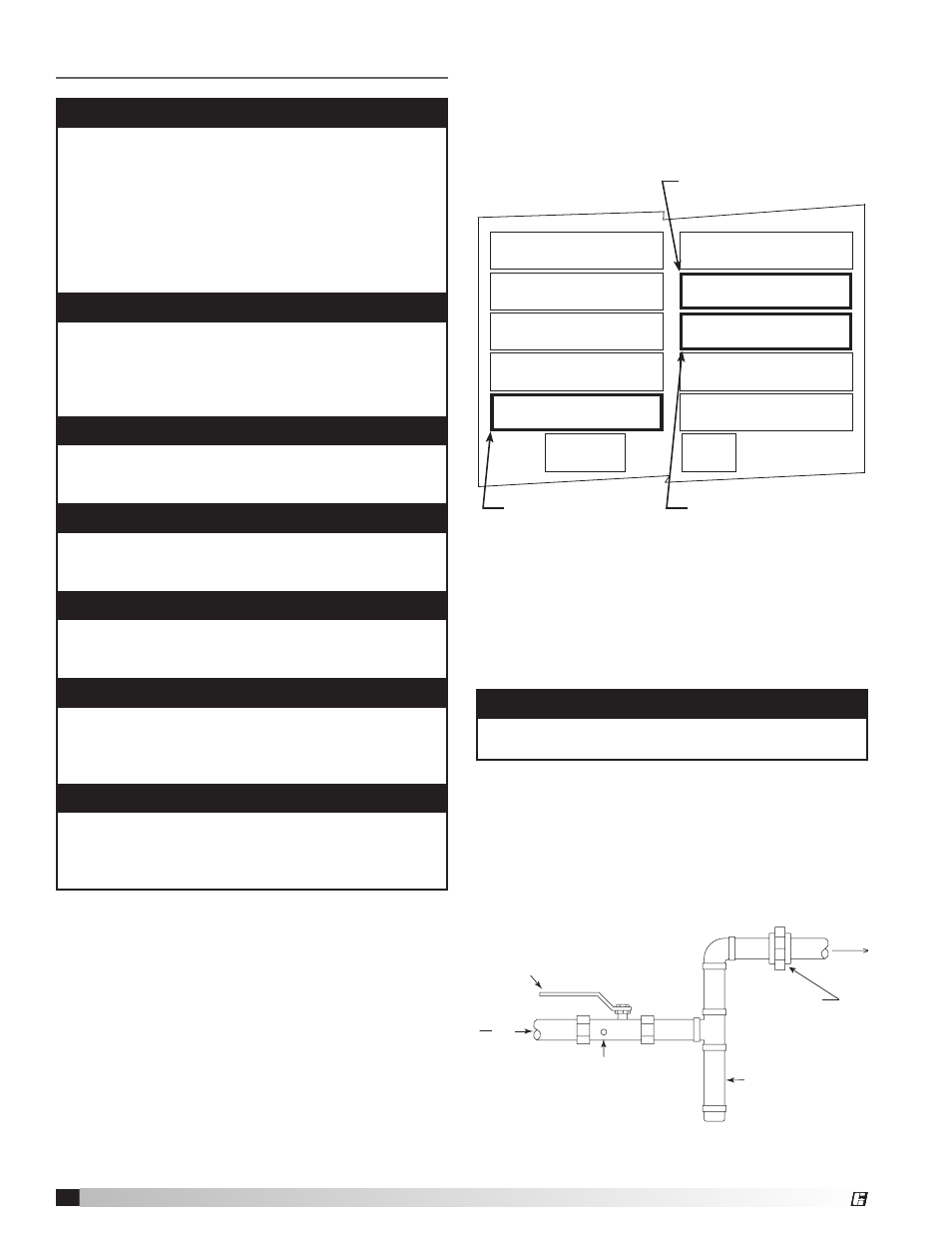

The unit’s direct gas nameplate states the requirements

for the gas being supplied to the unit. The direct gas

nameplate is located on the outside of the unit on the

control center side.

Type of gas

“ W.C.

“ W.C.

“ W.C.

F

PSI

“ W.C.

“ W.C.

MAX BTU/HR

BTU/H MAX

NORMAL MANIFOLD

PRESSURE

PRESSION DÕADMISSION

NORMALE

MIN GAS

PRESSURE

PRESSION DE GAZ

MIN BURNER

PRESSURE DROP

PERTE MIN DE PRESSION

DANS LE BRULEUR

TYPE OF GAS

NATURE DU GAZ

MIN BTU/HR

BTU/H MIN

MIN GAS PRESSURE

FOR MAX OUTPUT

PRESSION DE GAZ MIN

POUR PUISSANCE MAX

MAX BURNER

PRESSURE DROP

PERTE MAX DE PRESSION

DANS LE BRULEUR

MAX GAS

PRESSURE

PRESSION DE GAZ

MAX

DESIGN ∆T

∆T NORMALE

EQUIPPED FOR

CONCU POUR

SCFM

“ W.C.

EXTERNAL STATIC PRESSURE

PRESSION STATIQUE EXTERIEURE

AGAINST

CONTE

Maximum gas pressure

Minimum gas pressure for

maximum output

2. Install Additional Regulator if Required

When the supply gas pressure exceeds the maximum

gas pressure shown on the direct gas nameplate, an

additional regulator (by others) is required to reduce

the pressure. The regulator must have a listed leak

limiting device or it must be vented to the outdoors.

3. Connect the Supply Gas Line

A manual shut off valve (gas cock), 1/8 in. plugged

test port and 6 in. drip leg must be installed prior to

the gas train. The valve and the test port must be

accessible for the connection of a test gauge. Supply

gas connections must be made by a qualified installer

and are not furnished by Greenheck.

To

Controls

Gas Cock

From

Gas

Supply

6 in. Trap

1/8 in. Plugged Tap

Ground Joint Union

Supply Gas Line

NOTE

The regulator located inside the unit is used to

adjust the unit’s maximum output temperature.

Direct Gas Nameplate