Start-up direct gas, Check the supply gas pressure, Check the pilot gas pressure – Greenheck Fan Make-Up Air Unit VSU User Manual

Page 10: Set the burner air pressure differential, Measuring the pressure drop

10

Model VSU Make-Up Air

®

®

®

®

®

1. Check the Supply Gas Pressure

Check the supply gas pressure and compare it with

the unit’s nameplate pressure requirements. Adjust

the supply regulator as needed until the supply gas

pressure is within the specified range. The direct gas

nameplate is located on the outside of the unit on the

control center side.

2. Check the Pilot Gas Pressure

Check the pilot gas pressure. The recommended

gas pressure is 3 in. wc. Adjust the pilot regulator as

needed. See the Gas Train Layout in the Reference

section for the location of the pilot pressure test port

and pilot regulator.

Start-Up Direct Gas

IMPORTANT

For proper unit function and safety, follow the start-

up procedure in the exact order that it is presented.

IMPORTANT

This start-up should begin after all of the installation

procedures and the blower start-up have been

completed.

The proper static pressure should be between 0.625

and 0.675 inches wc (155.68 and 168.64 Pa). If

needed, evenly adjust the baffles on both sides of the

burner, keeping the burner centered in the opening

until the required pressure is obtained.

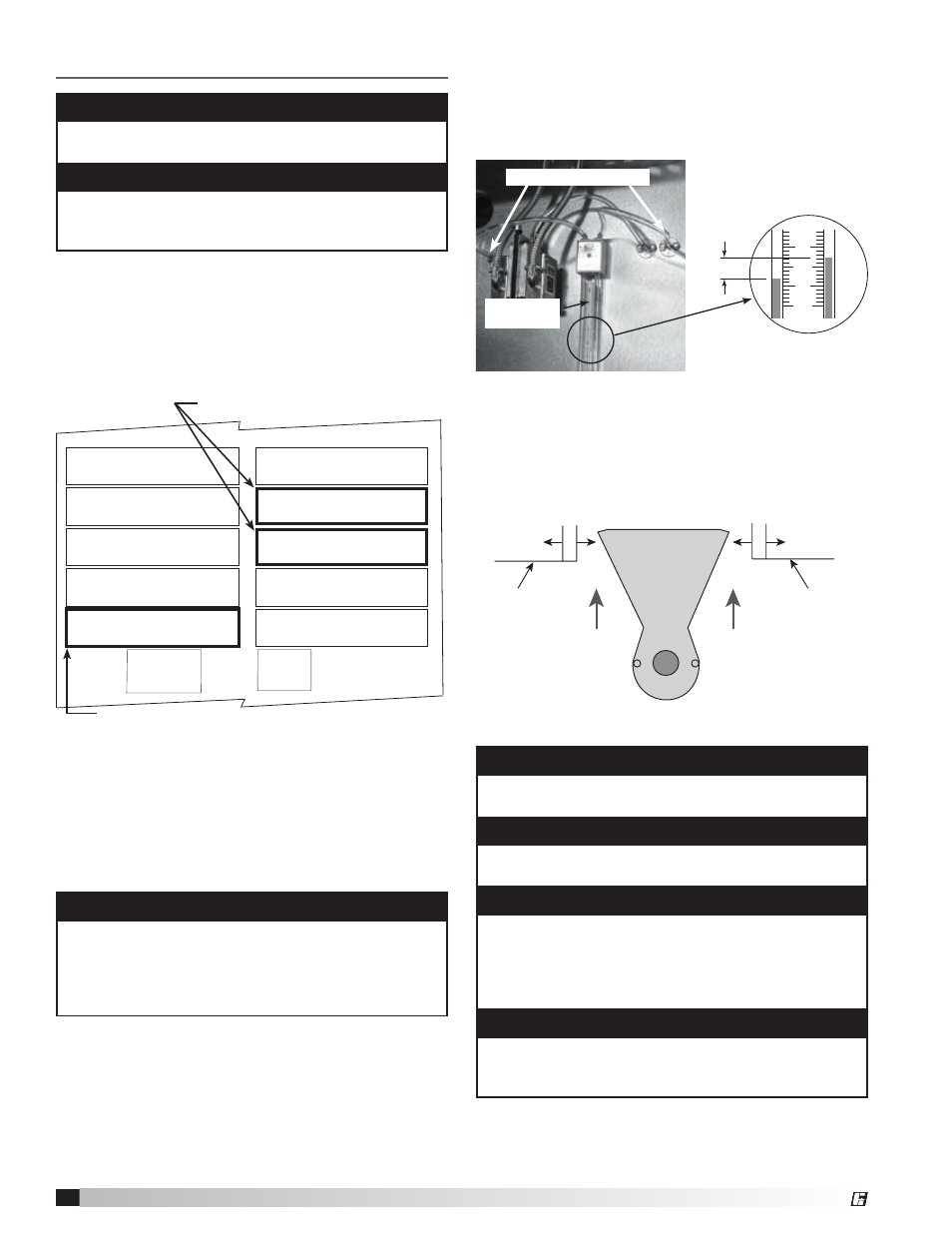

3. Set the Burner Air Pressure Differential

With the fan running and discharging 70ºF (21ºC) air,

connect a U-Tube manometer to the outer sensing

probes (see below) and measure the static pressure

across the burner.

IMPORTANT

Proper air velocity over the burner is critical on direct

fired gas units. If the air velocity is not within the unit

specifications, the unit will not operate efficiently,

may have sporadic shutdowns, and may produce

excessive carbon monoxide (CO) or other gases.

Adjustable

Baffle

Airflow

Burner

Adjustable

Baffle

Airflow

Burner and Baffles

9

8

7

6

0.625 - 0.675 in. wc

Outer Sensing Probes

Measuring the Pressure Drop

U-Tube

Manometer

NOTE

The pressure drop was set at the factory and may

not need adjustment.

NOTE

When required pressure is obtained, be sure to

reconnect the outer sensing probes.

IMPORTANT

This process may need to be repeated until the

proper pressure is achieved. This adjustment

will change the air quantity delivered by the unit

and therefore the air quantity delivered should be

rechecked. Refer to the Blower Start-Up section.

NOTE

To increase the static pressure decrease the

opening. To decrease the static pressure increase

the opening.

Direct Gas Nameplate

“ W.C.

“ W.C.

“ W.C.

F

PSI

“ W.C.

“ W.C.

MAX BTU/HR

BTU/H MAX

NORMAL MANIFOLD

PRESSURE

PRESSION DÕADMISSION

NORMALE

MIN GAS

PRESSURE

PRESSION DE GAZ

MIN BURNER

PRESSURE DROP

PERTE MIN DE PRESSION

DANS LE BRULEUR

TYPE OF GAS

NATURE DU GAZ

MIN BTU/HR

BTU/H MIN

MIN GAS PRESSURE

FOR MAX OUTPUT

PRESSION DE GAZ MIN

POUR PUISSANCE MAX

MAX BURNER

PRESSURE DROP

PERTE MAX DE PRESSION

DANS LE BRULEUR

MAX GAS

PRESSURE

PRESSION DE GAZ

MAX

DESIGN ∆T

∆T NORMALE

EQUIPPED FOR

CONCU POUR

SCFM

“ W.C.

EXTERNAL STATIC PRESSURE

PRESSION STATIQUE EXTERIEURE

AGAINST

CONTE

Minimum and maximum gas

pressures for maximum output

Type of gas