Set the maximum firing rate, Maxitrol series 14, Regulators and modulating valves – Greenheck Fan Make-Up Air Unit VSU User Manual

Page 11: Set the minimum firing rate

11

Model VSU Make-Up Air

®

®

®

®

®

4. Set the Maximum Firing Rate

Monitor the unit’s actual temperature rise by placing

a thermocouple in the unit’s inlet and a second in the

discharge, three duct diameters downstream of the

burner.

Send the unit to maximum fire by disconnecting and

isolating the wire connected to Terminal 4 on the

Maxitrol 14.

While monitoring the units temperature rise, set the

maximum firing rate by adjusting the regulator until the

designed temperature rise is achieved. After setting the

maximum firing rate, reconnect the wire to the amplifier.

NOTE

The minimum setting for the maximum firing rate

may be higher than required. This is acceptable. The

burner will modulate as needed.

NOTE

Do not set the burner maximum firing rate based on gas

pressure. It should be set based on the unit’s designed

temperature rise shown on the direct gas label.

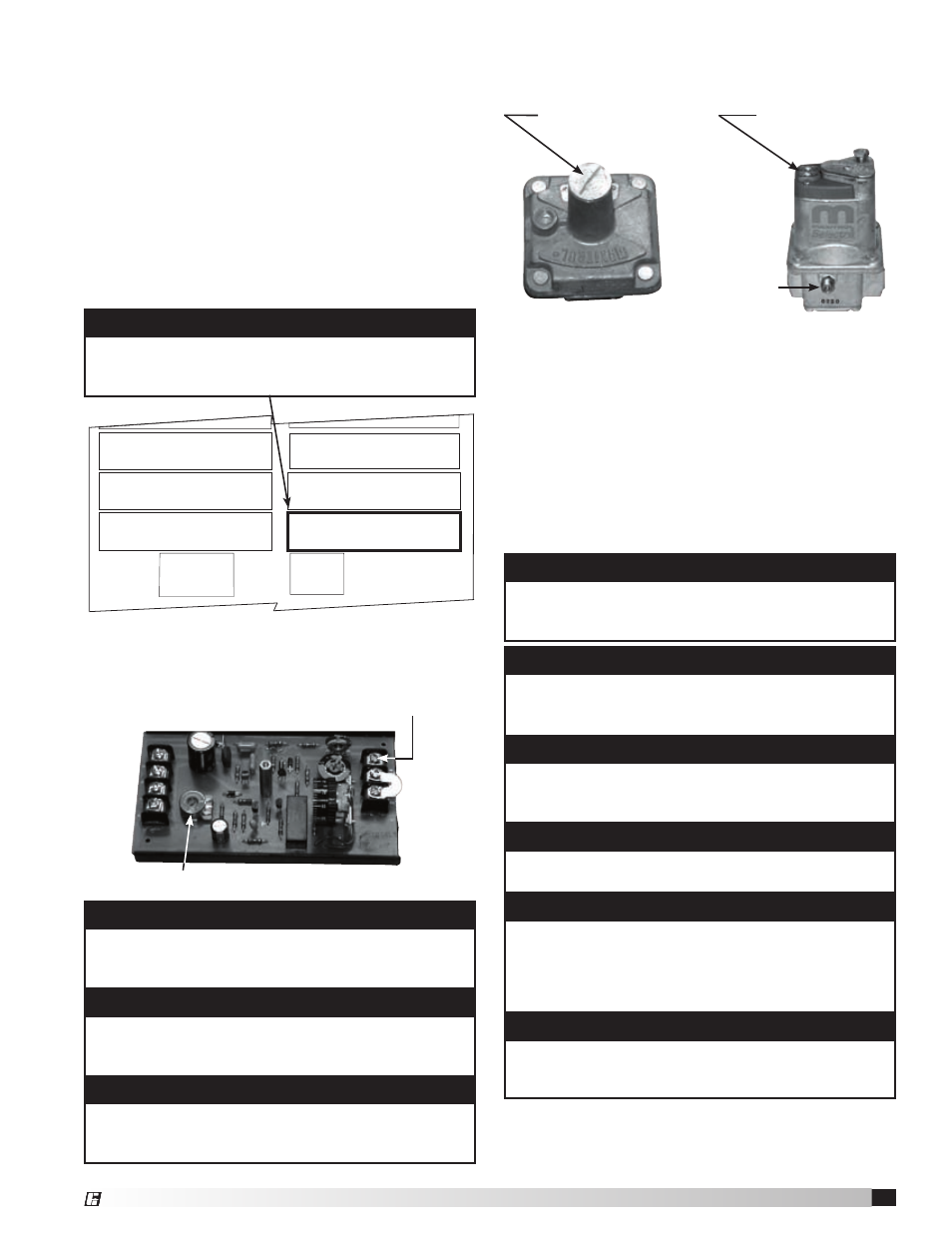

Maxitrol Series 14 —

7 terminals

Remove the wire from terminal #4 to

send the unit to maximum fire

Low fire time delay setting (75% of maximum)

Remove cap to access

maximum firing rate

adjustment

Remove one wire to

send the unit to the

minimum firing rate

Separate Regulator and Modulating Valves

Regulators and Modulating Valves

Minimum

firing rate

adjustment

IMPORTANT

Setting the maximum firing rate during mild weather

conditions may cause the high limit to trip out during

extreme conditions requiring manual resetting.

NOTE

Gas trains are equipped with either separate

regulators and modulating valves or with a

combined modulating valve.

NOTE

Clockwise rotation increases the temperature

rise, counterclockwise rotation decreases the

temperature rise.

5. Set the Minimum Firing Rate

Disconnect and isolate one of the wires running to

the modulating valve to send the unit to its minimum

firing rate. Set the minimum firing rate by adjusting the

needle valve shown above.

After setting the minimum firing rate, shut off the

pilot to ensure that the flame safeguard can still read

the main flame signal. Reconnect the wire to the

modulation valve and open the pilot shut-off valve.

IMPORTANT

The proper minimum firing rate setting results in a

small ribbon of continuous flame which covers the

flame road and runs across the entire burner.

IMPORTANT

Do not allow the disconnected wire to come in

contact with a potential ground. Damage to the

amplifier or transformer could result.

NOTE

Gas trains are equipped with separate regulators

and modulating valves.

NOTE

Adjusting the maximum and minimum firing rate

requires the inlet air sensor to be set higher than the

outdoor air temperature in order to start the burner(s).

Once high and low fire have been set, the inlet air

sensor should be set to the desired temperature.

NOTE

Counterclockwise rotation increases the minimum

fire rate setting, clockwise rotation decreases the

setting.

Direct Gas Nameplate

“ W.C.

“ W.C.

F

PSI

“ W.C.

MIN GAS

PRESSURE

PRESSION DE GAZ

MIN BURNER

PRESSURE DROP

PERTE MIN DE PRESSION

DANS LE BRULEUR

TYPE OF GAS

NATURE DU GAZ

MAX BURNER

PRESSURE DROP

PERTE MAX DE PRESSION

DANS LE BRULEUR

MAX GAS

PRESSURE

PRESSION DE GAZ

MAX

DESIGN ∆T

∆T NORMALE

EQUIPPED FOR

CONCU POUR

SCFM

“ W.C.

EXTERNAL STATIC PRESSURE

PRESSION STATIQUE EXTERIEURE

AGAINST

CONTE