Aligning table – Grizzly 17" Heavy Duty-Bandsaw G0513X2BF User Manual

Page 38

-36-

G0513 Series Bandsaws

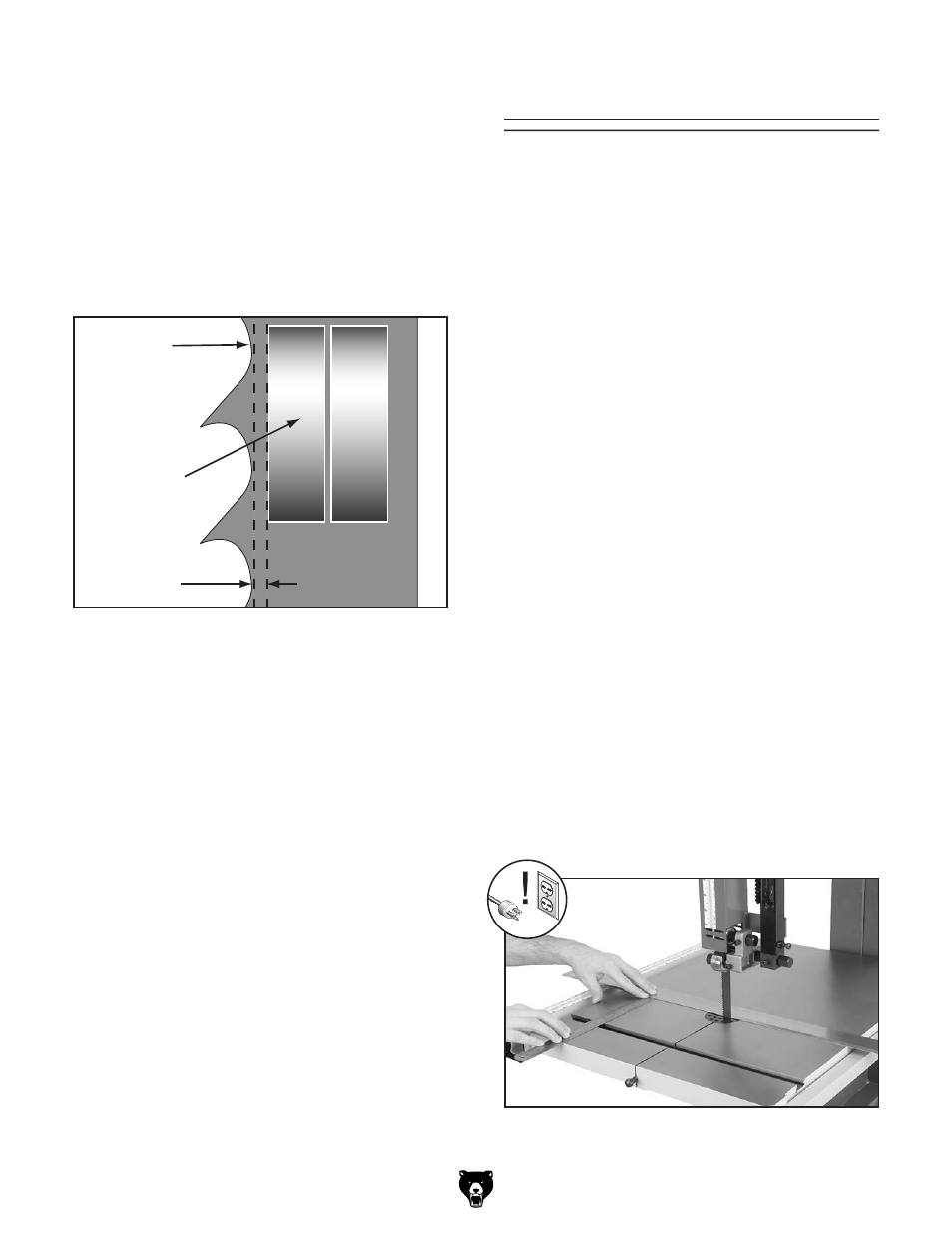

3. loosen the lateral rod cap screw and slide

the guide block to position the blade guides

approximately 0.016" behind the blade gul-

lets, as illustrated in

Figure 50.

Note: The 0.016" spacing is ideal, although

with larger blades it may not be possible.

In such cases, adjust the guide bearings as

far forward as possible to the blade gullets,

and still maintain the proper support bearing

spacing adjustment.

Blade

Gullet

Guide

Bearings

0.016"

Gap

Figure 50. lateral adjustment of blade guides.

4. tighten the lateral rod cap screw to secure

the setting.

5. loosen both bearing rotation cap screws.

6. rotate the knurled knob to position the bear-

ings approximately 0.004" away from the

blade.

7. re-tighten the cap screws to lock the blade

guide bearings in position.

Aligning Table

to ensure cutting accuracy when the table is first

installed, the table should be aligned so that the

miter slot is parallel to the bandsaw blade. this

procedure works best with a wide (

3

⁄

4

") blade

installed.

Tools Needed

Qty

straightedge ...................................................... 1

Fine ruler .......................................................... 1

square ............................................................... 1

Wrench or socket 13mm ................................... 1

To align the table so the miter slot is parallel

to the bandsaw blade:

1. Make sure that the blade is tracking properly

and that it is correctly tensioned.

2. disCoNNECt BaNdsaW FroM poWEr!

3. loosen the trunnion bolts that secure the

table.

4. place an accurate straightedge along the

blade. the straightedge should lightly touch

both the front and back of the blade.

Note: Make sure the straightedge does not

go across a tooth.

5. use a fine ruler to gauge the distance

between the straightedge and the miter slot.

the distance you measure should be the

same at the front and the back of the table

(see

Figure 51).

Figure 51. Measuring for miter slot to be parallel

with blade.