Thickness stop calibration – Grizzly G0689 User Manual

Page 33

g0689 13" planer

-31-

Thickness Stop

Calibration

the thickness stop is set at the factory and should

not require adjustment. however, with extended

use, it is possible that the thickness stop may

come out of adjustment. if you notice that use of

the thickness stop is not producing results to your

standards, you may need to adjust it.

Tools Needed

Qty

hex Wrench 4mm .............................................. 1

hex Wrench 5mm .............................................. 1

Wrench 8mm ..................................................... 1

To adjust the thickness stop:

1. using a caliper to accurately measure the

thickness, plane a board to exactly 1

1

⁄

4

".

2. diSConnECt planEr FroM poWEr!

3. remove the side and top covers by perform-

ing

Steps 2–3 from Drive Belt, starting on

Page 28. replace the elevation crank and

raise the cutterhead approximately 1".

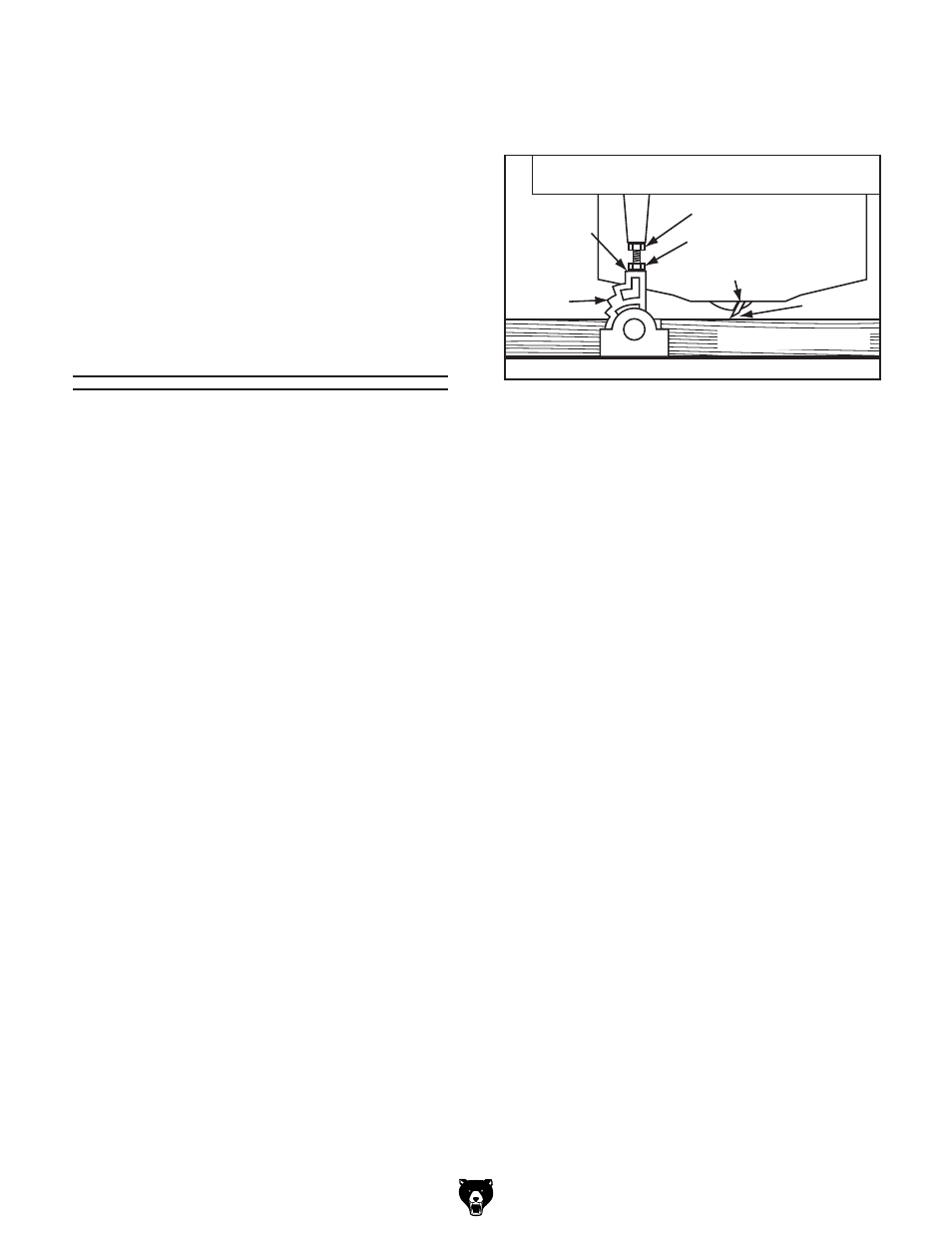

figure 42.

Thickness stop adjustment.

8jiiZg]ZVY@c^[Z

Hide7dai

IdjX]^c\

IdjX]^c\

& I]^X`Ldg`e^ZXZ

I]^X`cZhh

Hide

AdX`Cji

5. place the 1

1

⁄

4

" thick board on the table and

lower the cutterhead until the knife just

touches the board when the knife is at its low-

est position (turn the belt pulley to rotate the

cutterhead as needed).

6. loosen the lock nut and adjust the stop bolt

as needed until it just touches the thickness

stop, then re-tighten the lock nut.

7. reassemble the machine, then check to see

if the thickness stop is producing the desired

results. repeat as necessary.

4. loosen the lock nuts, then turn each adjust-

ment bolt so that it just touches the cam

when the lock lever is approximately halfway

through its travel, then tighten the lock nuts.

Note: It is important that all four adjustment

bolts are set equally. Failure to do this could

cause the cutterhead to move during use,

resulting in inconsistent planing.

4. locate the thickness stop bolt and lock nut.

Manually rotate the thickness stop to the

position shown in

figure 42.