Troubleshooting – Grizzly G0689 User Manual

Page 26

-24-

g0689 13" planer

review the troubleshooting and procedures in this section to fix or adjust your machine if a problem devel-

ops. if you need replacement parts or you are unsure of your repair skills, then feel free to call our technical

Support at (570) 546-9663.

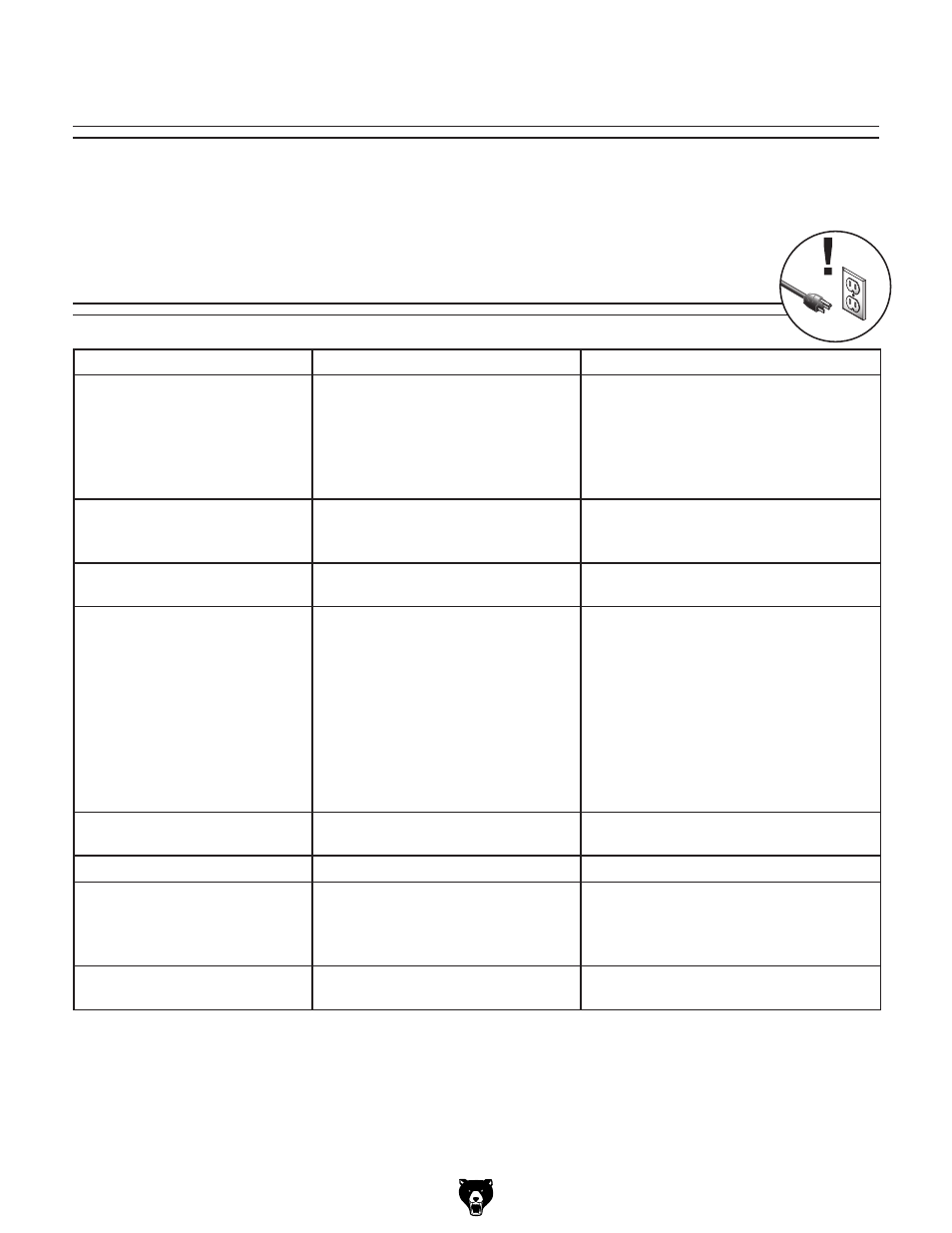

SECTION 7: SERvICE

Troubleshooting

Symptom

possible Cause

possible Solution

Motor will not run.

1. no power to planer.

2. Motor overload protection tripped.

3. defective switch or loose wiring.

4. Brushes are at fault.

1. Check power supply.

2. turn planer

OFF. reset overload protection

(

Page 15).

3. inspect all lead connections on switch/

motor for loose or open connections.

4. inspect/replace.

Fuses or circuit breakers blow.

1. Short circuit in line cord or plug.

2. Brushes are at fault.

1. repair or replace cord or plug for damaged

insulation and shorted wires.

2. inspect/replace.

Motor overheats or operates at

limited rpM.

1. Motor overloaded during operation.

2. Brushes are at fault.

1. reduce cutting load; take lighter cuts.

2. inspect/replace.

Motor stalls or shuts off during a

cut.

1. Cut is too deep.

2. Motor overload protection tripped.

3. Short circuit in motor or loose

connections.

4. Circuit breaker tripped.

5. Brushes are at fault.

1. reduce depth-of-cut.

2. turn planer

OFF. reset overload protection

(

Page 15).

3. repair or replace connections on motor

for loose or shorted terminals or worn

insulation.

4. install correct or repair circuit breaker;

reduce number of machines running on

that circuit.

5. inspect/replace.

Cutterhead slows or squeals when

cutting, especially on start-up.

1. Belt worn out.

2. Brushes are at fault.

1. replace belt (

Page 28).

2. inspect/replace.

infeed/outfeed rollers not rotating.

1. Chain and sprockets are worn.

1. replace chain and sprockets.

Vibration when running or cutting.

1. Knives are dull.

2. loose or damaged cutterhead.

3. damaged belt.

4. Worn cutterhead bearings.

1. replace knives.

2. tighten or replace cutterhead.

3. replace (

Page 28).

4. Check/replace cutterhead bearings.

Boards don't feed properly into

machine.

1. Knives are dull.

2. Sawdust in feed rollers.

1. replace knives.

2. Clean feed roller (

Page 29)