Depth-of-cut, Elevation crank, Depth-of-cut gauge – Grizzly G0689 User Manual

Page 18

-16-

g0689 13" planer

Depth-of-Cut

the planing depth is controlled by the cutterhead

elevation crank on top of the planer. turning the

crank clockwise raises the cutterhead and turning

it counterclockwise lowers the cutterhead.

the Model g0689 has multiple methods for

determining the depth-of-cut depending on your

planing needs. the elevation crank, cutterhead

elevation scale, thickness stop, and depth-of-cut

gauge all provide a means for accurately measur-

ing the material that will be removed from wood

workpieces.

Elevation Crank

the elevation crank provides a simple and accu-

rate method for producing consistent-depth cuts

on multiple passes. the pitch of the elevation

leadscrew is 16 threads per inch, meaning that

every turn of the crank will lower the cutterhead

1

⁄

16

". using this as a base, you can make passes

with a depth-of-cut of

1

⁄

64

",

1

⁄

32

",

3

⁄

64

" and

1

⁄

16

" by

turning the crank

1

⁄

4

turn,

1

⁄

2

turn,

3

⁄

4

turn, and one

full turn, respectively (

figure 14).

Note: Any time you switch directions with the

cutterhead elevation crank, there will be a small

amount of backlash—so the first turn of the crank

after switching directions will be slightly less than

1

⁄

16

". However, as long as you move the crank in

the same direction during operation, backlash will

not be a factor.

&

¿

)

Ijgc

2

&

¿

+)

&

¿

'

Ijgc

2

&

¿

('

(

¿

)

Ijgc

2

(

¿

+)

&Ijgc

2

&

¿

&+

9dlc

Je

figure 14.

Crank elevation increments.

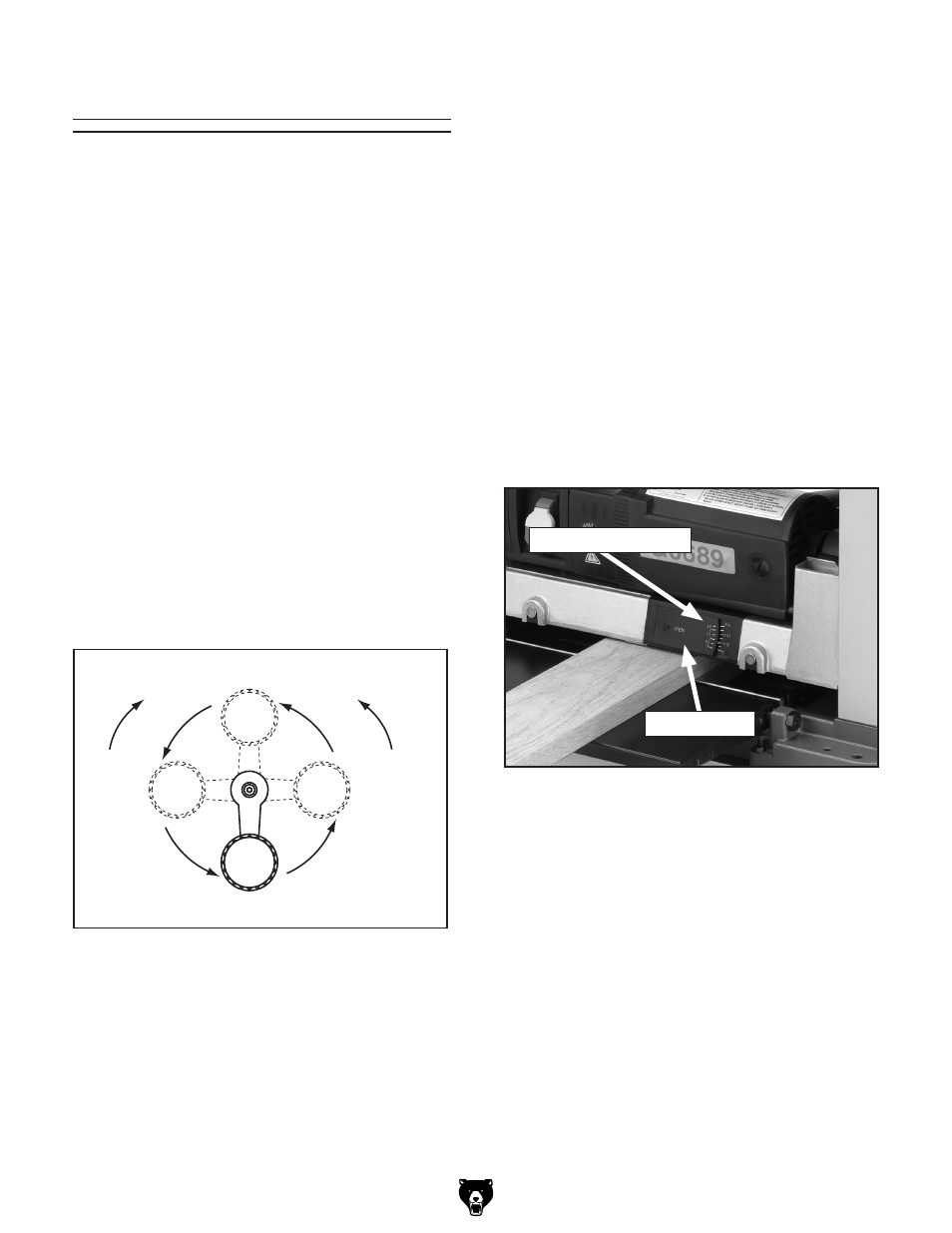

Depth-of-Cut Gauge

the depth-of-cut gauge can be used to accurately

and directly measure the depth-of-cut, indepen-

dent of workpiece thickness. By measuring the

difference in elevation of the top surface of the

workpiece and the cutterhead knives (at their low-

est points), the value displayed on the depth-of-

cut gauge accurately represents the thickness of

material that will be removed in that pass.

To use the depth-of-cut gauge:

1. lower the cutterhead assembly to just above

your workpiece, then place your workpiece

under the center of the cutterhead assem-

bly, as shown in

figure 15. (Make sure the

workpiece only extends 1"–2" under the front

of the gauge and does not extend into the

path of the cutterhead knives.)

2. Continue lowering the cutterhead assembly

until you see the depth-of-cut gauge indicator

begin to move. turn the cutterhead elevation

crank until the desired depth-of-cut is indi-

cated by the gauge.

3. remove the workpiece, then make your plan-

ing pass.

Note: The depth-of-cut gauge should only be

used for approximate measurements. If pre-

cise workpiece thicknesses are needed, use

calipers to ensure your workpieces meet your

standards.

Note: Sliding the gauge cover to the "Open"

position disables the gauge.

figure 15. depth-of-cut gauge

.

depth-of-Cut gauge

gauge Cover