Goodman Mfg A/GPG13 M User Manual

Page 34

34

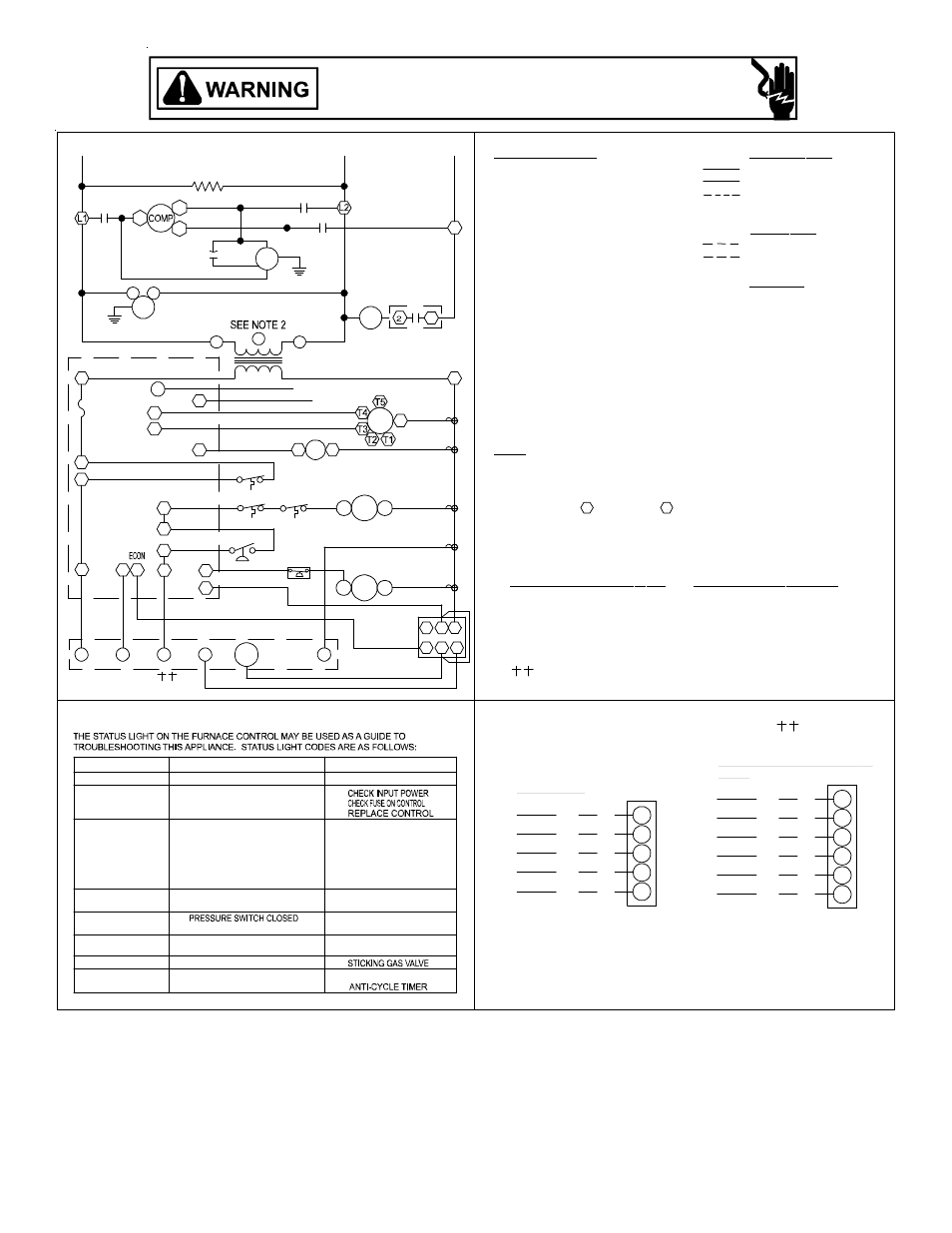

GPG13(48,60)3** WIRING DIAGRAM

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING THIS

UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

YL

0140G01002 REV. A

HIGH PRESSURE SWITCH

HPS

BL/PK BLUE/PINK

LOW VOLTAGE

FACTORY W IRING

LINE VOLTAGE

BL BLUE

BR BROWN

WIRE CODE

BK BLACK

LOW VOLTAGE

WH W HITE

RD RED

PK PINK

GR GREEN

PU PURPLE

YL YELLOW

OR ORANGE

FIELD WIRING

HIGH VOLTAGE

OPTIONAL HIGH VOLTAGE

T1 - LOW SPEED

T2 - MED. SPEED

T3 - HIGH SPEED

HEATING SPEED (WHITE W IRE)

208-230/3/60

W

Y1

Y2

C

G

R

WH

PU

BL

YL

GR

RD

2 STAGE COOLING WITH ECONOMIZER

OPTION

ALS

COMP

COMPONENT LEGEND

COMPRESSOR

L3

L2

EM

IIC

IGN

GND

FS

GV

C

CH

F

FUSE

FC

EVAPORATOR MOTOR

FLAME SENSOR

EQUIPMENT GROUND

IGNITOR

GAS VALVE

CONTACTOR

CRANKCASE HEATER

FAN CAPACITOR

NOTES

RS

TR

PLF

PS

VM

VMR

ROLLOUT SW ITCH

TRANSFORMER

PRESSURE SW ITCH

VENT MOTOR

VENT MOTOR RELAY

LIMIT SW ITCH

LS

L3

VMR

4

VM

C

IIC

FS

3

EM

C

NOTE 7

CONDENSER MOTOR

CM

NOTE 3

CH

SUPPLY VOLTAGE

208-230/3/60

L1

CM

T3

T3

T2

FC

N

TR

1

2

1

FS

D1

C

H

3

C

T1

L

F

NOTE 7

EM

T1

C

T2

IGN

T5 - HIGH SPEED

T4 - LOW SPEED

C

GV

6

5

1

2

3

4

NOTE

C

5

PLF

Y

C

W

R

G

WH

GR

RD

BL

NO ECONOMIZER

-

CHECK

GAS FLOW

GAS VALVE

FLAME SENSOR

FLAME ROLLOUT

GAS PRESSURE

CHECK

CHECK

PRESSURE SWITCH

PRESSURE SWITCH

3 MIN. COMP.

BAD SWITCH

MAIN LIMIT OPEN

AUX. LIMIT OPEN

BAD SWITCH

PS

ALS

RS

11

8

10

12

6

3

Y/Y2

W

Y1

IIC

9

7

5

R

G

TO THERMOSTAT

FAULT

OR

OR

EQUIP. STATUS

INTERNAL CONTROL

NO POWER OR

NORMAL OPERATION

IGNITION FAILURE

SWITCH

OPEN ROLLOUT

OPEN

SWITCH

PRESSURE SWITCH

WITHOUT INDUCER ON

COMPRESSOR

OPEN LIMIT SWITCH

OUTPUT DELAY

FALSE FLAME SENSED

OPEN AUX. LIMIT

1 BLINK

ON

OFF

5 BLINKS

4 BLINKS

2 BLINKS

6 BLINKS

3 BLINKS

STATUS LIGHT

INSTALLER/SERVICEMAN

4

LS

VMR

INTEGRATED IGNITION CONTROL

FEMALE PLUG/CONNECTOR

AUXILIARY LIMIT SWITCH

1. REPLACEMENT WIRE MUST BE THE SAME SIZE AND TYPE OF

INSULATION AS ORIGINAL .(USE COPPER CONDUCTOR ONLY).

2. FOR 208 VOLT TRANSFORMER OPERATION MOVE BLACK WIRE

FROM TERMINAL 3 TO TERMINAL 2 ON TRANSFORMER.

5. ACCESSORY ECONOMIZER PLUG (ON SELECT MODELS) ADJACENT

TO BLOWER HOUSING IN RETURN AIR COMPARTMENT.

3. CRANKCASE HEATER NOT SUPPLIED ON ALL UNITS.

4. FOR DIFFERENT THAN FACTORY SPEED TAP. CHANGE COOLING

SPEED AT MOTOR T4 AND T5 TERMINALS. CHANGE HEATING

SPEED AT MOTOR T1, T2 AND T3 TERMINALS.

7. L1 AND L2 ON ICC CONTROL IS 24V INPUT.

6. USE COOPER CONDUCTORS ONLY.

USE NEC CLASS 2 W IRE.

COOLING SPEED (YELLOW

W IRE)

THERMOSTAT FIELD WIRING

HPS

1

2