Tension adjustment assembly, Trunnions – Grizzly G0513P User Manual

Page 58

-56-

G0513 Series Bandsaws

3. using a rag and mineral spirits, wipe off any

existing grease and sawdust build-up on the

rack (see

Figure 83).

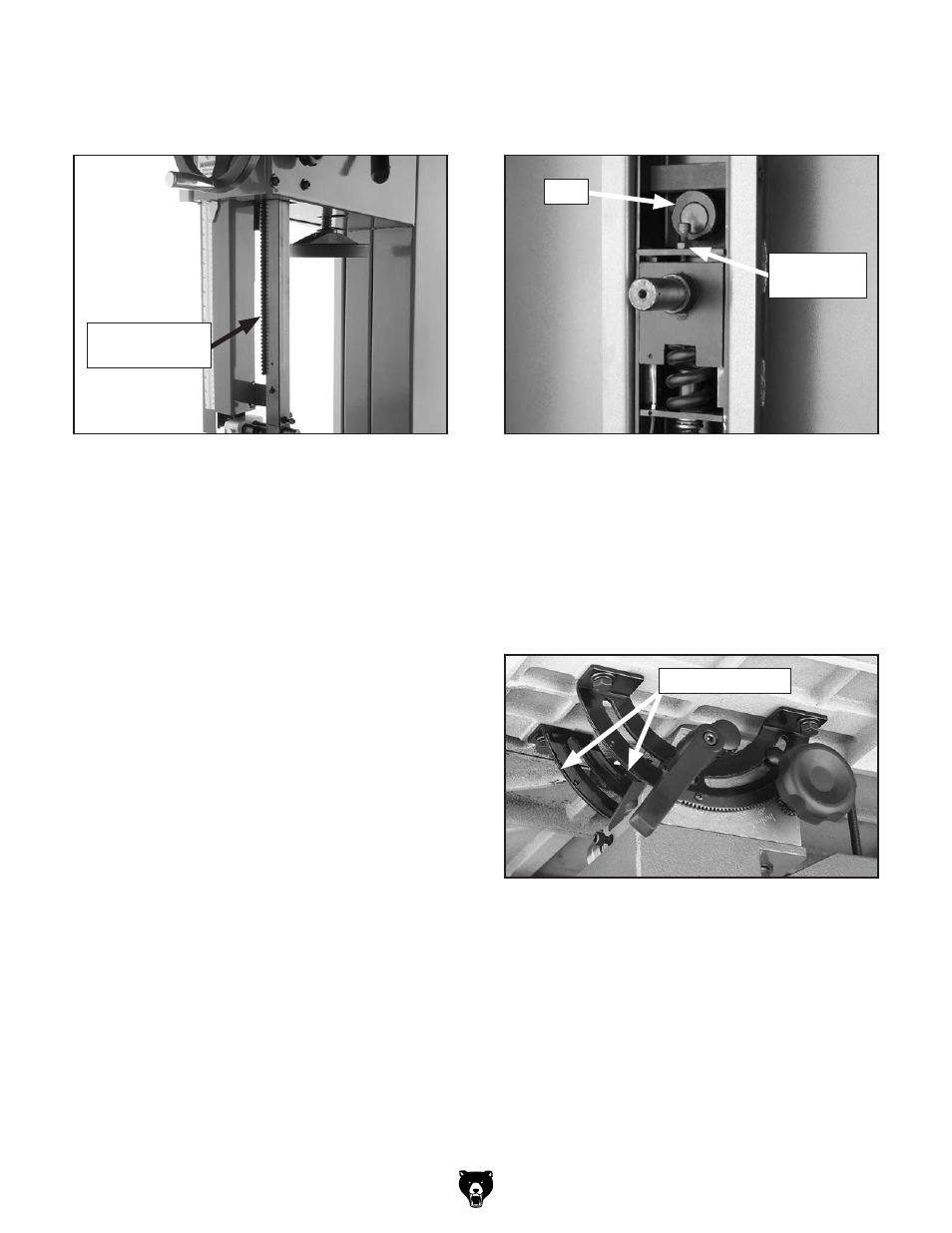

Figure 83. Example of rack lubrication location.

rack Exposed

for lubrication

4. apply a thin coat of lubricant to the rack.

5. Move the blade post up and down several

times to distribute the lubricant, then remove

any excess grease to help reduce potential

sawdust build-up.

Tension Adjustment Assembly

lubrication type ........ gl2 grease or Equivalent

amount .................................................thin Coat

Frequency .......................................... as Needed

To lubricate the tension adjustment assem-

bly:

1. disCoNNECt BaNdsaW FroM poWEr!

2. open the top wheel cover and look through

the top of the wheel.

3. using a rag and mineral spirits, wipe off any

existing grease and sawdust build-up on the

blade tension adjustment assembly and ten-

sion lever cam.

Figure 84. Example of tension adjustment

assembly locations (top wheel removed for

clarity).

Cam

adjustment

assembly

Trunnions

Models g0513 and g0513p have steel trunnions

that can be cleaned and lubricated with gl2

grease or equivalent along the sliding surfaces

(see

Figure 85) when necessary.

Figure 85. trunnion lubrication location

(g0513 & g0513p only).

sliding surfaces

Models g0513X2, g0513X2B, g0513X2BF, and

g0513X2F have cast iron trunnions that produce

a fine graphite powder over time that acts as a

lubricant. We recommend not adding lubricant

to the trunnions which could make a sticky sub-

stance that would prevent smooth movement.

4. apply a thin coat of lubricant to the tension

adjustment assembly and tension lever cam

(see

Figure 84).