Designed for superior finish quality, The best spray pattern in the industry! delta xt, Spray atomization comparison – Graco Inc. XT Series User Manual

Page 5

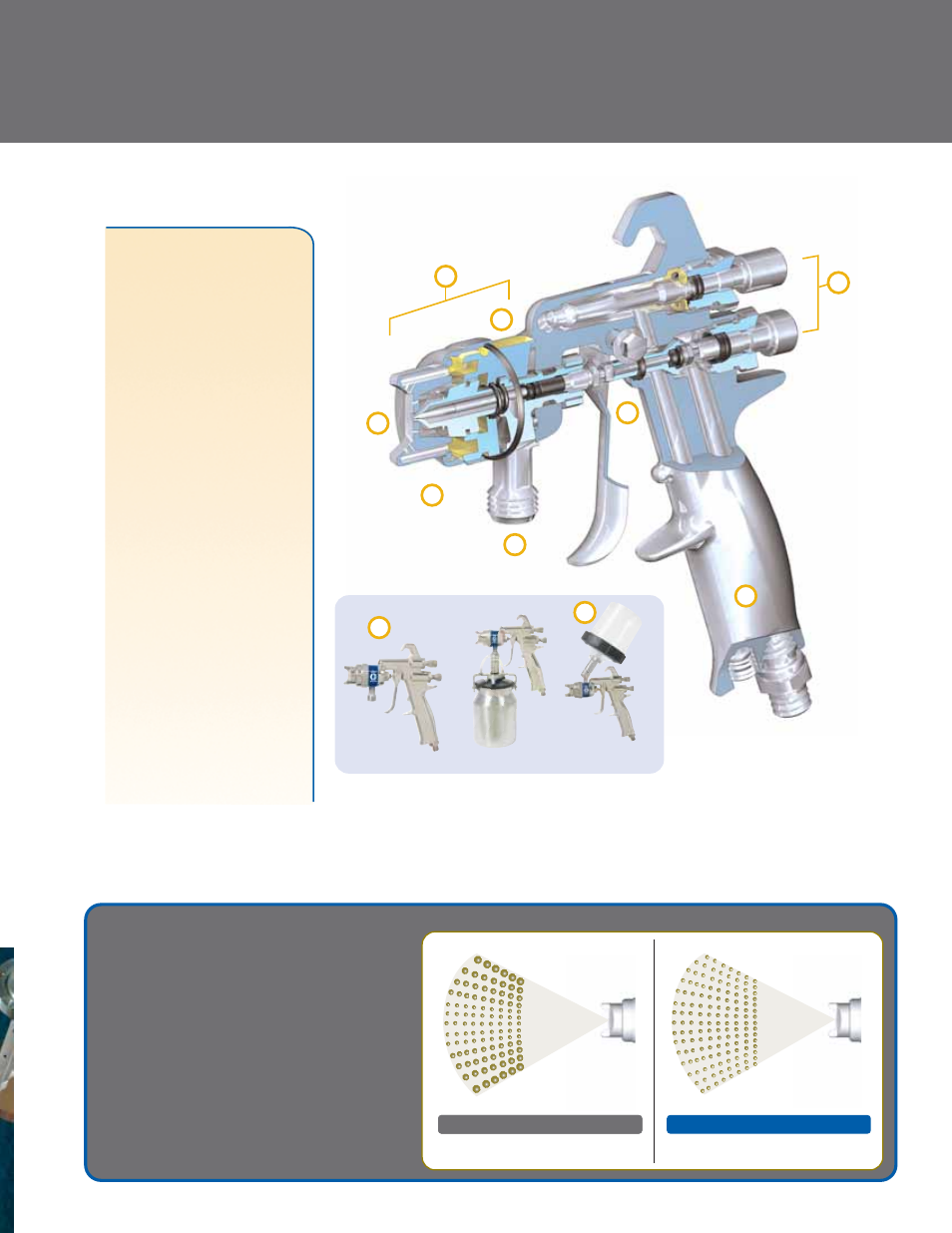

Designed for Superior Finish Quality!

1. State-of-the-art Fluid Section

Provides the best finish quality

in the industry

2. New Ring Design

Prevents air cap from moving

while tightening

3. Removable Needle Tip

Reduces repair costs

4. Improved Air Cap and Nozzle Seating

Maintains pattern consistency,

increases product longevity with

stainless steel construction, and

reduces inventory with common

nozzle sizes

5. More Robust Fluid Intake

Fluid intake allows up to 300 PSI

6. Dual Valve Design

Decreases the number of parts

for less maintenance, and reduces

the overall weight of the gun

7. Smooth, Curved Handle

Improves operator comfort, reduces

fatigue and makes clean up easy

8. Easy Adjustments

Quickly and easily adjust the

fan pattern and fluid flow

9. Feed Options

Choose from pressure, siphon

or gravity feed

10. Gravity Feed Cup

Reduces cleaning and labor costs

The Best Spray Pattern in the Industry!

DELTA XT

5

3

1

6

7

4

2

SPRAY ATOMIZATION COMPARISON

9

8

PRESSURE FEED SIPHON FEED GRAVITY FEED

10

The Delta Spray XT Series not only has the best

pattern balance in the industry, but it is also the

most consistent.

Unlike the competition, the fluid atomized

particles remain the same size from one side

of the spray pattern to the other – reducing the

need for spray overlap and delivering an

outstanding finish every time!

COMMON COMPETITOR

GRACO XT SERIES

Inconsistent particle size

Consistent particle size deliver

produce an uneven finish

an even finish every time!