Nstallation, Igging – Goodman Mfg SS-CPG180-240 User Manual

Page 13

SS-CPG180-240

www.goodmanmfg.com

13

P

roduct

S

PecificationS

r

ooF

C

UrB

i

nsTallaTion

— r

igging

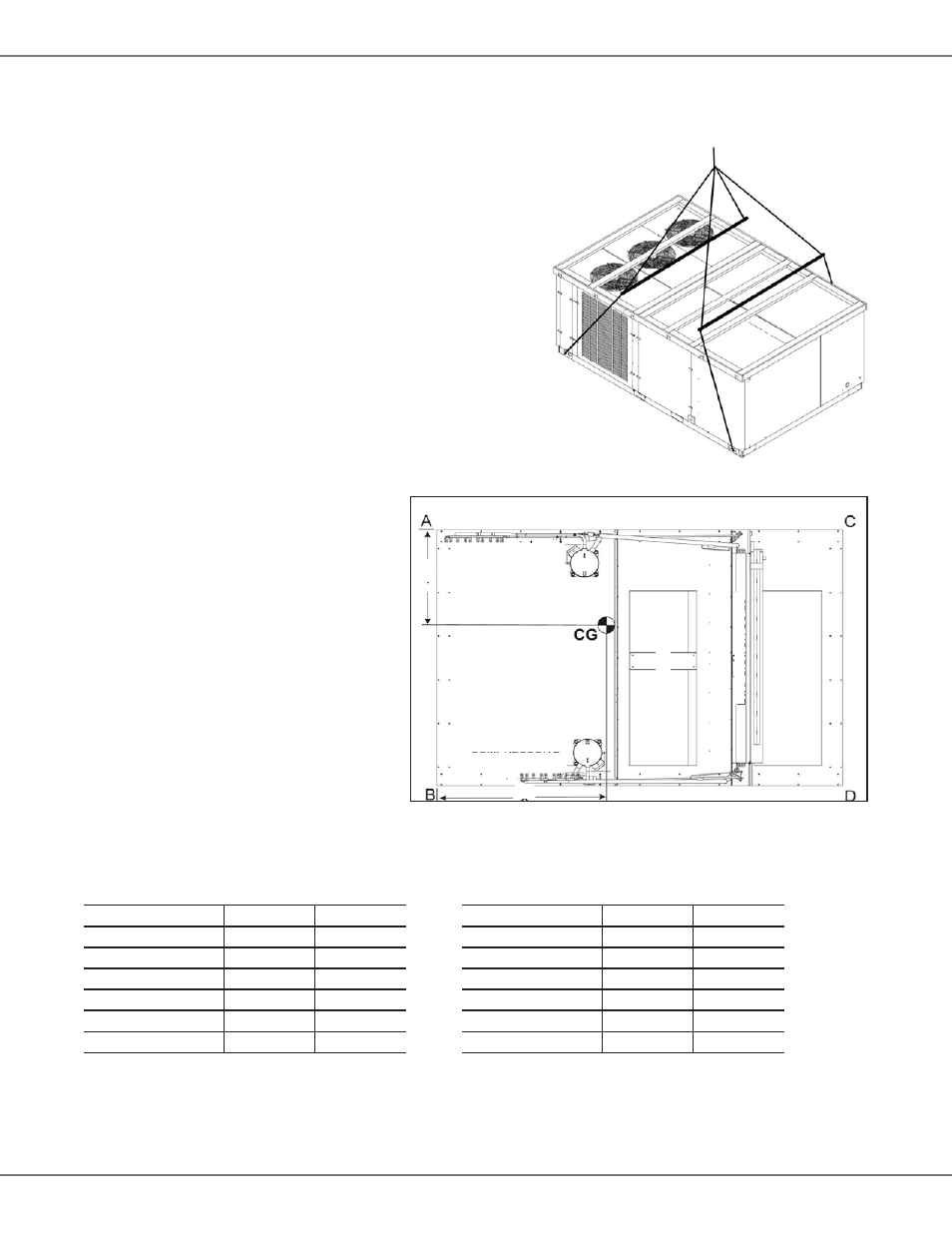

Provisions for forks have been included in the unit base frame. No other

fork locations are approved.

• Unit must be lifted by the four lifting holes lo-

cated at the base frame corners.

• Lifting cables should be attached to the unit with shackles.

• The distance between the crane hook and the top of the unit must not

be less than 60”.

• Two spreader bars must span over the unit to prevent damage

to the cabinet by the lift cables. Spreader bars must be of suf-

ficient length so that cables do not come in contact with the unit

during transport. Remove wood struts mounted beneath unit

base frame before setting unit on roof curb. These struts are in-

tended to protect unit base frame from fork lift damage. To remove

the struts, extract the sheet metal retainers and pull the struts

through the base of the unit. Refer to rigging label on the unit.

Important: If using bottom discharge with roof curb, duct-work should be

attached to the curb prior to installing the unit. Duct-work dimensions are

shown in Roof Curb Installation Instructions Manual.

Refer to the Roof Curb Installation Instructions for

proper curb installation. Curbing must be installed

in compliance with the National Roofing Contractors

Association Manual.

Lower unit carefully onto roof mounting curb. While

rigging the unit, the center of gravity will cause the

condenser end to be lower than the supply air end.

Bring condenser end of unit into alignment with the

curb. With condenser end of the unit resting on curb

member and using curb as a fulcrum, lower opposite

end of the unit until entire unit is seated on the curb.

When a rectangular cantilever curb is used, take care

to center the unit. Check for proper alignment and

orientation of supply and return openings with duct.

To assist in determining rigging requirements, unit weights are shown to the right.

Note: These weights are calculated without installed accessories.

Corner & Center-of-Gravity Locations

40”

Compressor 1

R

etu

Rn

e

vapo

Ra

to

R

C

oil

S

uppl

y

Compressor 2

58”

15-Ton Weights

20-Ton Weights

Gas

Cooler

Gas

Cooler

Weight A

582

590

Weight A

645

644

Weight B

475

582

Weight B

527

525

Weight C

565

492

Weight C

589

504

Weight D

461

401

Weight D

481

412

Shipping Weight

2198

2080

Shipping Weight

2357

2202

Operating Weight

2083

1965

Operating Weight

2242

2085