0 critical clearances – FMC Corporation - Talstar FMC L06 User Manual

Page 55

Doc No: OMM50000903

Rev: B Page 55 of 65

Subject to contractual terms and conditions to the contrary, this document and all the information contained herein are the confidential and exclusive

property of FMC Technologies, and may not be reproduced, disclosed, or made public in any manner prior to express written authorization by FMC.

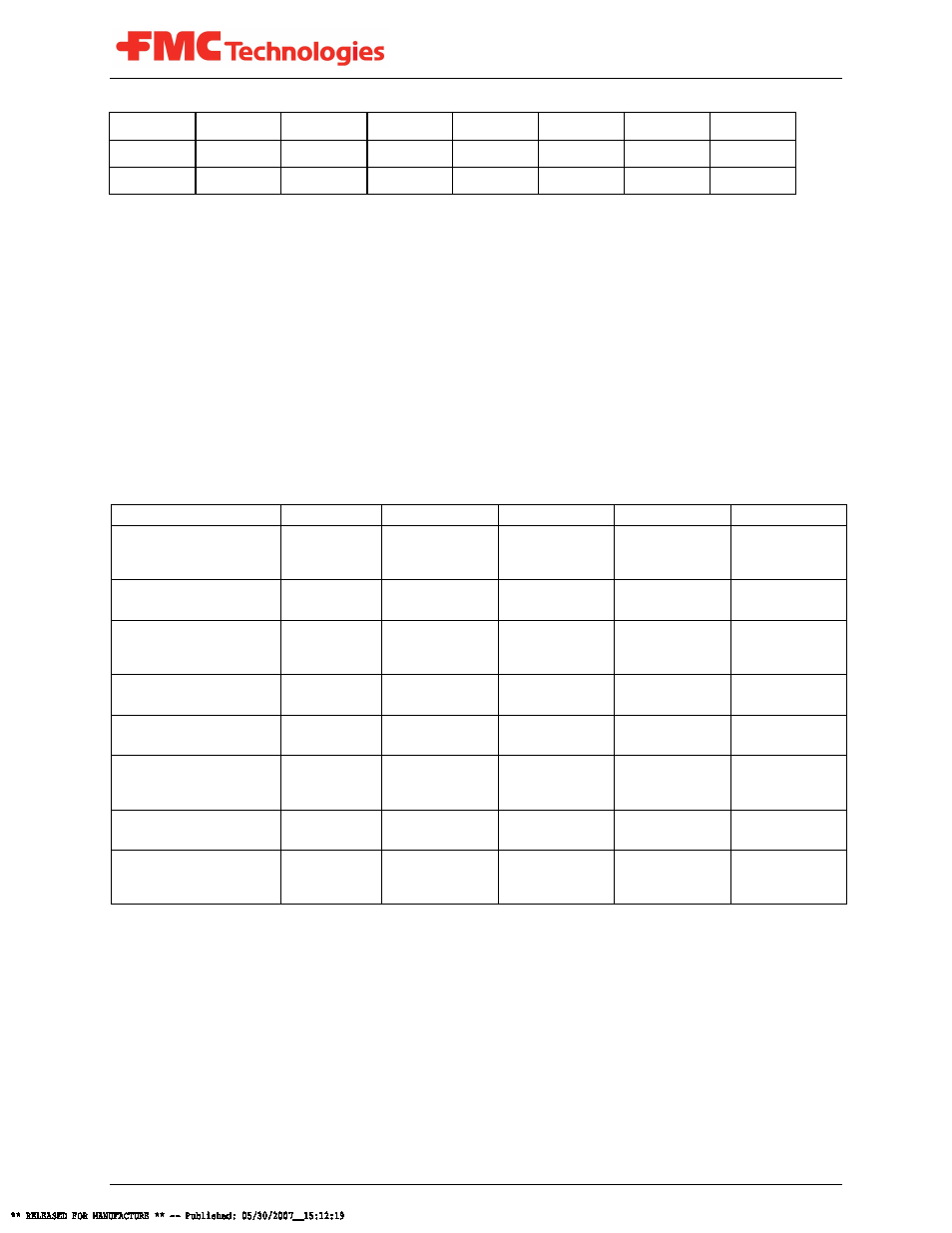

SIZE

0.500

0.625

0.750

0.875

1.000

1.125

1.250

Ft-lb

40

80

135

215

320

460

630

(N-m)

54

108

183

292

434

624

854

Table 5: Torque Values for Xylan-Coated Fasteners

12.0

Critical Clearances

When maintenance requiring disassembly of the power end is performed, the following

clearances should be checked to see if they are within factory specification or within

maximum allowable limits. Additional clearance is allowed for component wear. This

additional clearance is a maximum of .002 inches of total diametral wear that can be

added to the clearance values in Table 6. For radial clearance, use ½ of the total

diametral value.

All dimensions are shown in Inches.

DESCRIPTION

L06

L09

L11

L12

L16

Crankshaft

Throw Diameter

(Stroke)

1.50

2.25

2.75

3.00

4.00

Crankshaft Pin or

Journal (OD)

2.311/2.312 2.8743/2.8748 3.4990/3.4995 3.4990/3.4995 3.4990/3.4995

Connecting Rod /

Crank Clearance

(Max. Total)

0.003

0.003

0.003

0.003

0.003

Crosshead Diameter

(OD)

2.123/2.125

2.749/2.750

3.121/3.123

3.121/3.123

3.122/3.123

Crosshead

Cylinder Bore (ID)

2.126/2.128 2.7515/2.7535 3.1245/3.1260 3.1245/3.1260 3.1245/3.1260

Crosshead to Bore

Clearance (Max.

Total)

0.005

0.0045

0.005

0.005

0.005

Wrist Pin

Bushing Bore (ID)

.8755/.8765 1.0005/1.0015 1.2505/1.2515 1.2505/1.2515 1.2505/1.2515

Wrist Pin to Bore

Clearance (Max.

Total)

0.002

0.002

0.002

0.002

0.002

NOTE: Clearances shown are total diametral values: For radial clearance use ½ the

value shown.

Table 6: Clearance Chart

Metric Conversion:

1 inch = 25.4 mm

1 mm = 0.03937 inches