Performance verification tests, Required equipment, How to verify pressure – Fluke 700G User Manual

Page 17

Pressure Gauge

Performance Verification Tests

7

Performance Verification Tests

Fluke recommends certification each year. To re-certify, do the verification procedure. If

test points are out of tolerance, calibrate the Product and then re-verify. Use the

subsequent tests to make sure that the Product is in its specification limits.

Required Equipment

The equipment necessary for verification of the Product is shown in Table 2. If these

instruments are not available, you can replace them with other instruments that have the

same minimal specification requirements.

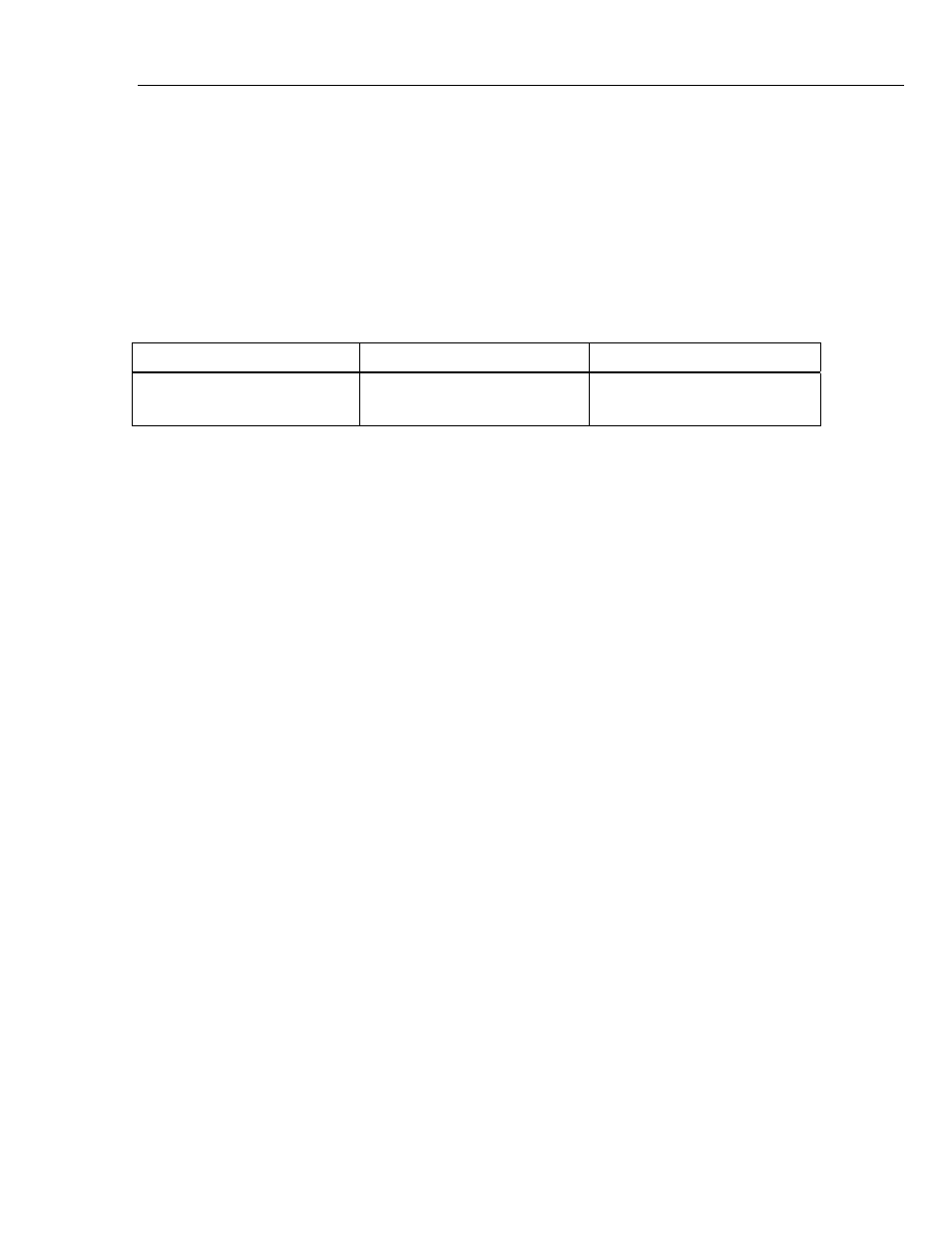

Table 2. Equipment Required for Verification

Equipment

Minimum Specification

Recommended Model

Dead Weight Tester

-14 to 10,000 psig

Accuracy: 0.012 % of Range

Pressurement P3000, P3100

How to Verify Pressure

For each procedure there is a table of test points and permitted Product indications. If the

result of the test is not in the range shown, the Unit Under Test (UUT) is out of tolerance

and must be calibrated or repaired. For Product support, see the “How to Contact Fluke”

section.

Follow these general instructions for all the tests:

•

Make sure the battery is fully charged.

•

Let the verification equipment warm-up for its specified time.

•

For each test, make sure the verification equipment is stable and that the “unsettled”

annunciator on the UUT is not shown.

1. Carefully attach the pressure fitting of the deadweight tester to the pressure port of

the UUT.

Note

Use plenty of TEFLON tape when you attach the pressure fitting.

The display reads 0.00 PSI with the deadweight tester opened to ambient air. If it

does not, push until the display shows 0.00 PSI.

2. Set up the deadweight tester for the sequence of psi inputs from Table 3. These inputs

will be put into the pressure port of the UUT.

3. Make sure the pressure has become stable at each input before you verify the display

indication.

4. Apply the inputs from Table 3.

5. Carefully vent all pressure and disconnect the UUT from the deadweight tester.