Festool 1400 EQ User Manual

Page 10

10

Milling cutters

Do not exceed the maximum speed specified on

the tool and/or keep to the speed range. Cracked or distorted

cutters must not be used.

You can turn the machine upside down when changing the

tool.

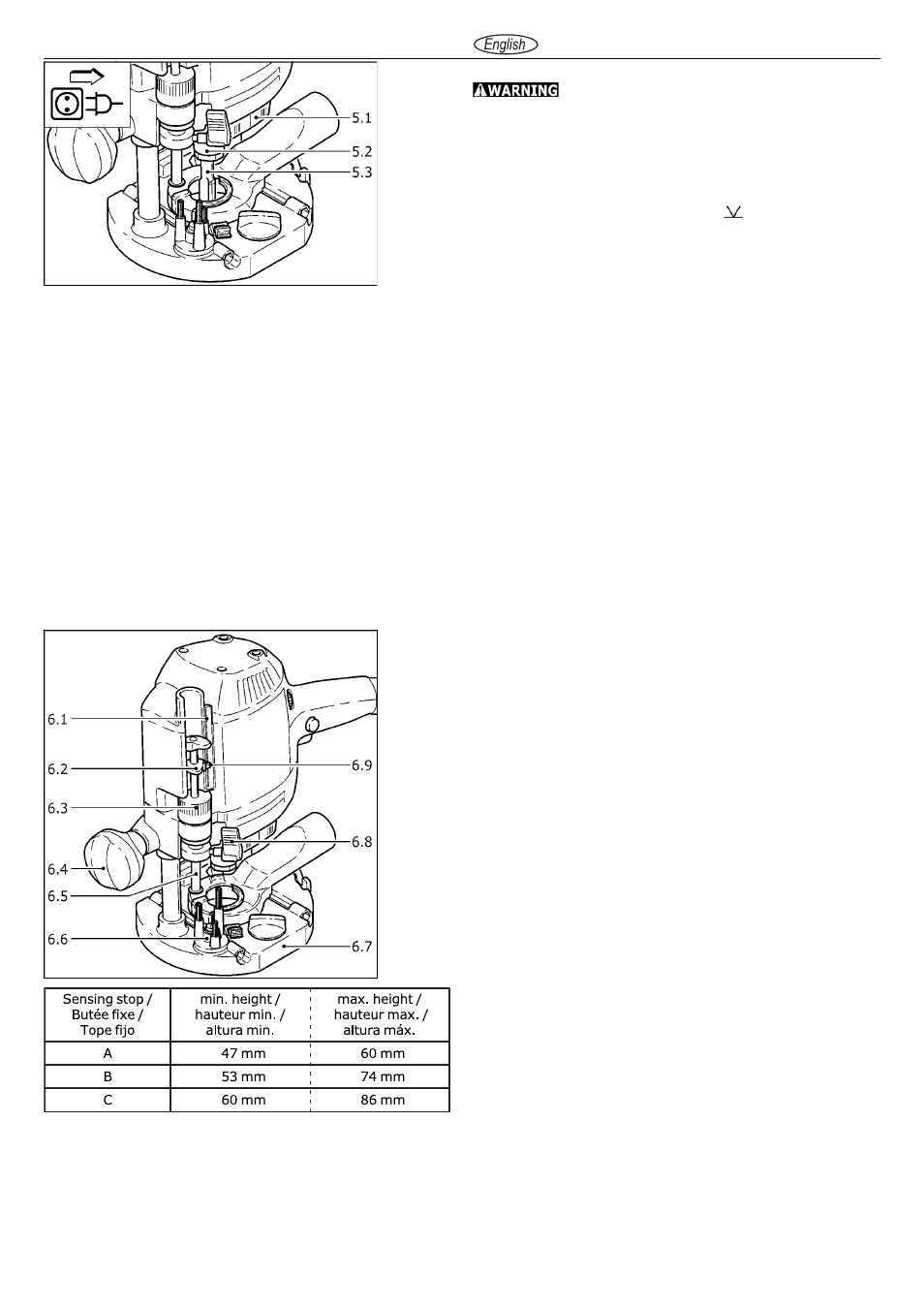

Inserting the tool

- Insert the router (5.3) into the open clamping collet as far as

possible, but at least up to the mark

on the router shank.

- Press the switch (5.1) for locking the spindle on the right-

hand side.

- Tighten the locking nut (5.2) with a 19 mm open-end spanner.

Removing the tool

- Press the switch (5.1) for locking the spindle on the left-

hand side.

- Undo the nut (5.2) using an open-end wrench (SW 19) until

you are able to remove the tool.

Note: the spindle lock only blocks the motor spindle in one

direction of rotation at any one time. Therefore when the nut

is undone or tightened, the wrench does not need to be offset

but can be moved back and forth like a ratchet.

Adjusting the milling depth

The milling depth is adjusted in three stages:

a) Setting the zero point

- Open the clamping lever (6.8) so that the stop cylinder (6.5)

can move freely.

- Place the router with router table (6.7) onto a smooth surface.

Open the rotary knob (6.4) and press the machine down

until the milling cutter rests on the base. Clamp the machine

tight in this position with the rotary knob (6.4).

- Press the stop cylinder against one of the three sensing stops

of the pivoted turret stop (6.6).

- The individual height of each sensing stop (see table beside)

can be adjusted with a screwdriver.

- Push the pointer (6.2) down so that it shows 0 mm on the

scale (6.1).

If the base position is incorrect, this can be adjusted with the

screw (6.9) on the indicator.

b) Setting the milling depth

The desired milling depth can be set either with the quick

depth adjustment or with the fine depth adjustment.

- Quick depth adjustment: Pull the stop cylinder (6.5) up

until the pointer shows the desired milling depth. Clamp the

stop cylinder in this position with the clamping lever (6.8).

- Fine depth adjustment: Clamp the stop cylinder with the

clamping lever (6.8). Set the desired milling depth by turning

the adjusting wheel (6.3) in. Turn the adjusting wheel to the

next mark on the scale to adjust the milling depth by 0.1 mm.

One full turn adjusts the milling depth by 1 mm. The maximum

adjustment range with the adjusting wheel is 8 mm.

c) Increasing the milling depth

- Open the rotary knob (6.4) and press the tool down until the

stop cylinder touches the sensing stops.

- Clamp the machine in this position by tightening the rotary

knob (6.4).

Clamping collet changing

- Press the switch (5.1) for locking the spindle on the left-

hand side. Fully unscrew the nut (5.2) and remove from

spindle together with the clamping collet.

- Press the switch (5.1) for locking the spindle on the right-

hand side. Insert a new clamping collet with nut into the

spindle and slightly tighten the nut. Do not tighten the nut

until a milling cutter has been fitted.