3. adjusting spark gaps – Hobart Welding Products CYBERTIG 350LX User Manual

Page 39

OM-356 Page 35

5-3.

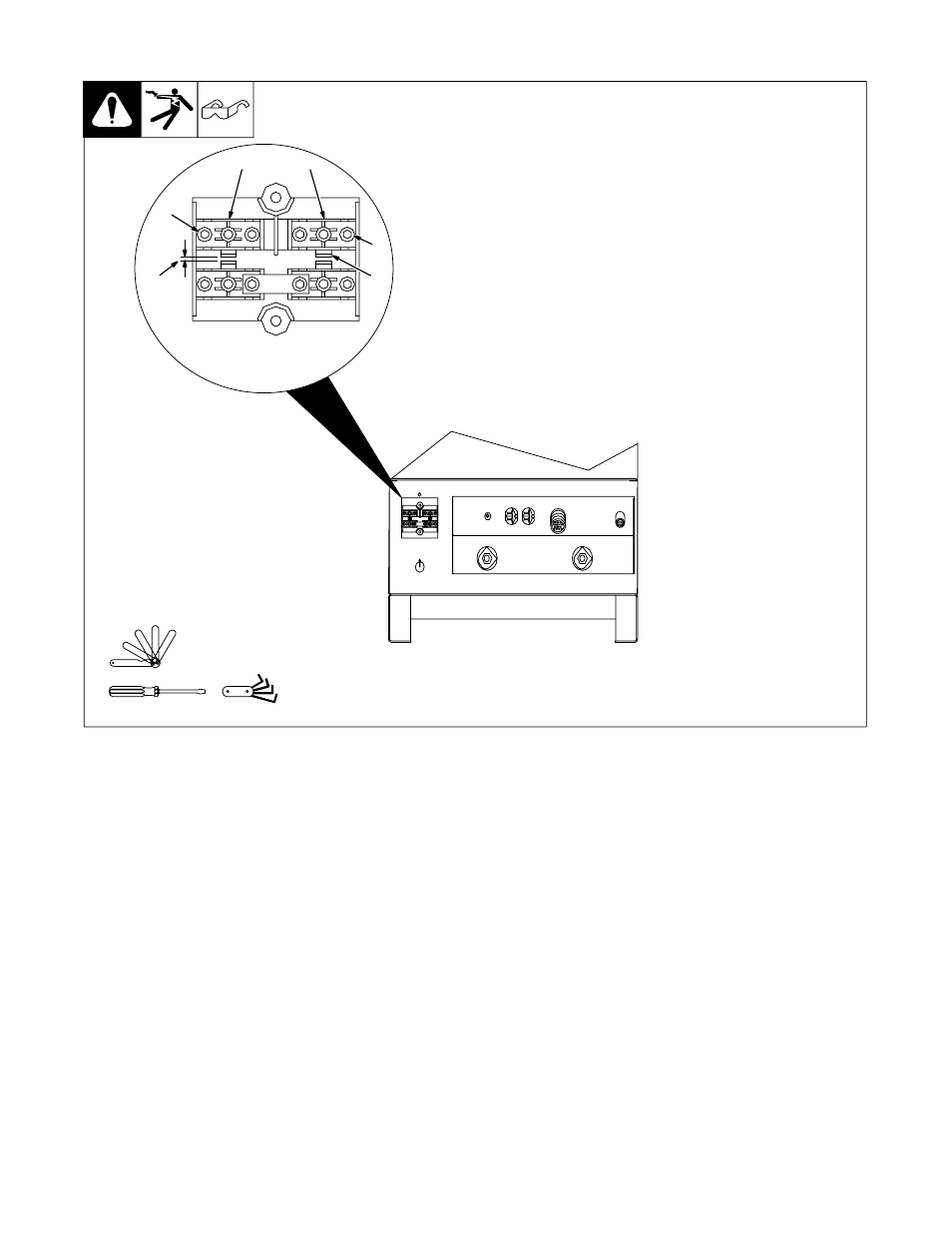

Adjusting Spark Gaps

Ref. ST-801 972-A

Y

Turn Off power before

adjusting spark gaps.

Open access door.

1

Tungsten End Of Point

Replace point if tungsten end dis-

appears; do not clean or dress

tungsten.

2

Spark Gap

Normal spark gap is 0.012 in (0.305

mm).

If adjustment is needed, proceed as

follows:

3

Adjustment Screws

Loosen screws. Place gauge of

proper thickness in spark gap.

4

Pressure Point

Apply slight pressure at point until

gauge is held firmly in gap. Tighten

screws to 12 in/lbs torque (overtigh-

tening will deform plastic base). Ad-

just other gap.

Reinstall access door.

Tools Needed:

5/32 in

0.012 in (0.305 mm)

1

4

3

4

3

2

See also other documents in the category Hobart Welding Products Tools:

- XTP (16 pages)

- IRONMAN M-10 (56 pages)

- HANDLER 140 217 694E (48 pages)

- OM-1594 (68 pages)

- DP-3035 (28 pages)

- 250A (32 pages)

- 175 (52 pages)

- OM-947 (48 pages)

- CHAMP 2060 (60 pages)

- 120 (48 pages)

- OM-494 (76 pages)

- 302 (40 pages)

- DP 3035-10 (32 pages)

- CHAMPION 4500 210 597J (52 pages)

- OLYMPIC R-115 (36 pages)

- HOOD XVX (20 pages)

- HANDLER 180 (52 pages)

- STICKMATE OM-950 (40 pages)

- 3035-20 (32 pages)

- H-9A Gun (24 pages)

- HANDLER 210 (52 pages)

- OM-948 (24 pages)

- 187 (52 pages)

- AIRFORCE 375 OM-2210 (32 pages)

- ARCSTAR OM-487 (60 pages)

- 300 AC (32 pages)

- Stickmate 205 AC (2 pages)

- AIRFORCE HP-25 TORCH (36 pages)

- 1435 (60 pages)

- AIRFORCE 250A (32 pages)

- 000 OM-945 194 047U (64 pages)

- 000 OM-945 (68 pages)

- CHAMPION OM-493 (56 pages)

- CHAMPION ELITE OM-240 438E (64 pages)

- AIRFORCE OM-230 455D (36 pages)

- SPOOL GUN DP 3035-20 (32 pages)

- OLYMPIC S-62 (36 pages)

- SPOOL GUN 3035-20 (2 pages)

- STICKMATE OM-949 (36 pages)

- HANDLER 210 OM-227 978B (52 pages)

- AIRFORCE OM-928 (32 pages)

- AIRFORCE 700I (40 pages)

- IRONMAN 230 (56 pages)

- HANDLER 210 MVP (56 pages)

- ARCSTAR 280 NT (52 pages)