12. setting pulse controls – Hobart Welding Products CYBERTIG 350LX User Manual

Page 31

OM-356 Page 27

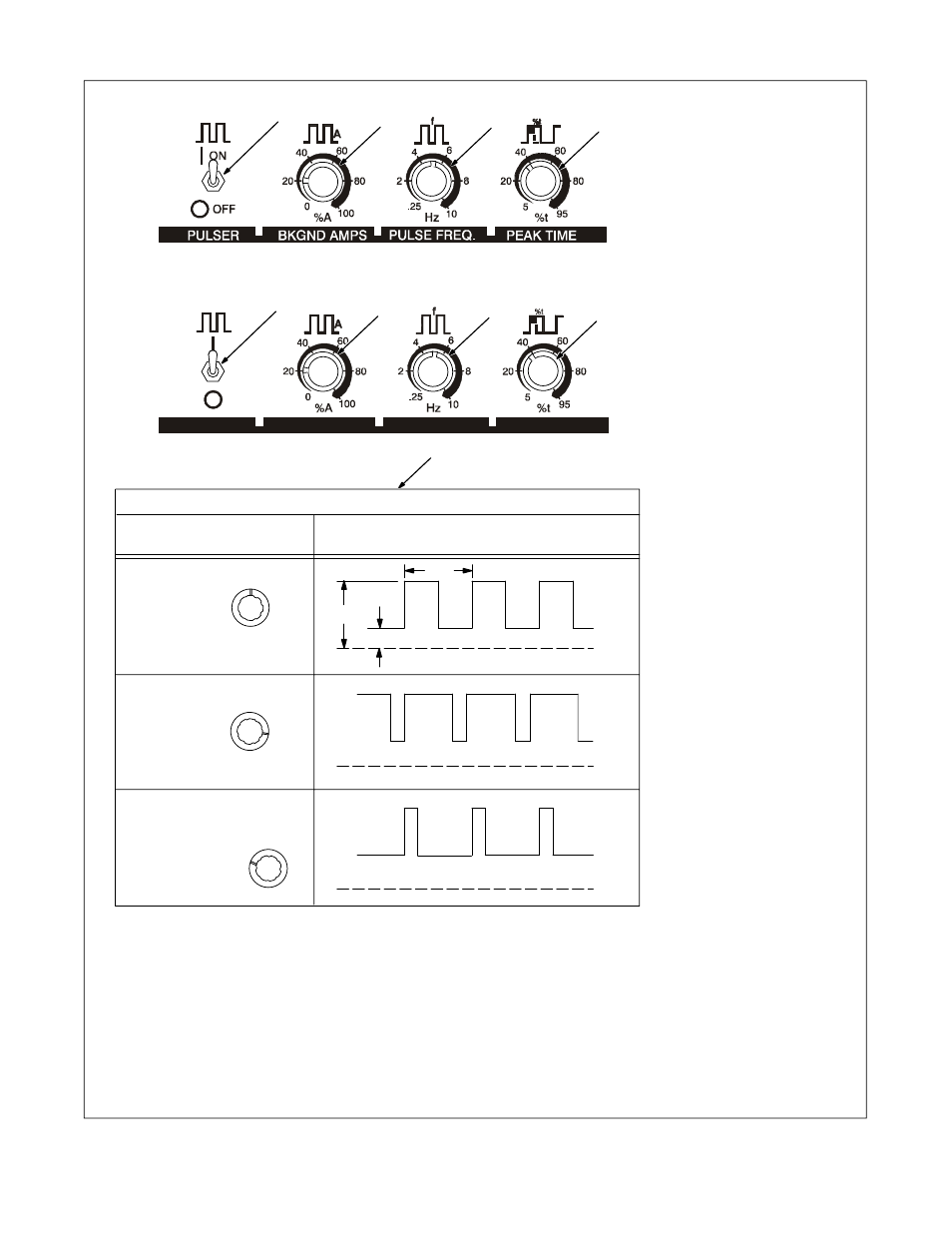

4-12. Setting Pulse Controls

1

On/Off Switch

Use switch to turn pulse function

On and Off.

2

Background Amps

Use Background Amps control to

set the low pulse of the weld am-

perage, which cools the weld

puddle and affects overall heat in-

put. Background Amps is set as a

percentage of peak amperage.

3

Pulse Frequency

A range from 0.25–10.0 pps

(pulses per second). Control is

used to determine appearance of

weld bead.

4

Peak Time

A range of 5–95% of each pulse

cycle can be spent at the peak

amperage level.

Peak amperage (3–400 amps), is

set with the Amperage Adjust-

ment control (see Section A).

Peak amperage is the highest

welding amperage allowed to oc-

cur in the pulse cycle. Weld pene-

tration varies directly with peak

amperage.

5

Pulsed Output Waveforms

Example shows affect changing

the Peak Time control has on the

pulsed output waveform.

Application:

Pulsing refers to the alternating

raising and lowering of the weld

output at a specific rate. The

raised portions of the weld output

are controlled in width, height,

and frequency, forming pulses of

weld output. These pulses and

the lower amperage level be-

tween them (called the back-

ground amperage) alternately

heat and cool the molten weld

puddle. The combined effect

gives the operator better control

of penetration, bead width,

crowning, undercutting, and heat

input. Controls can be adjusted

while welding.

Pulsing can also be used for filler

material addition technique

training.

Peak Amp

Bkg Amp

Balanced

More Time

At Peak

Amperage

More Time At

Background

Amperage

Pulsed Output Waveforms

Percent (%) Peak

Time Control Setting

(50%)

(80%)

(20%)

PPS

1

5

2

3

4

1

2

3

4

(CE Nameplate Only)