13. high frequency control, 14. optional sequence controls – Hobart Welding Products CYBERTIG 350LX User Manual

Page 32

OM-356 Page 28

4-13. High Frequency Control

Ref. ST-801 972

Y

Do not use high frequency while Shielded Metal Arc Weld-

ing (SMAW).

1

High Frequency Control

For GTAW, use control to set HF intensity. Set as low as possible.

Application:

If HF is present at the tungsten, the control is set high enough.

Arc rectification can occur when welding above 200 amps and/or

while welding with helium gas. If this condition occurs, increasing the

HF Intensity control towards maximum, may help to restabilize the

arc.

.

As high frequency intensity is increased, the possibility of inter-

fering with local electronic devices, especially communication

equipment, also increases. Set control as low as possible to

avoid such interference.

1

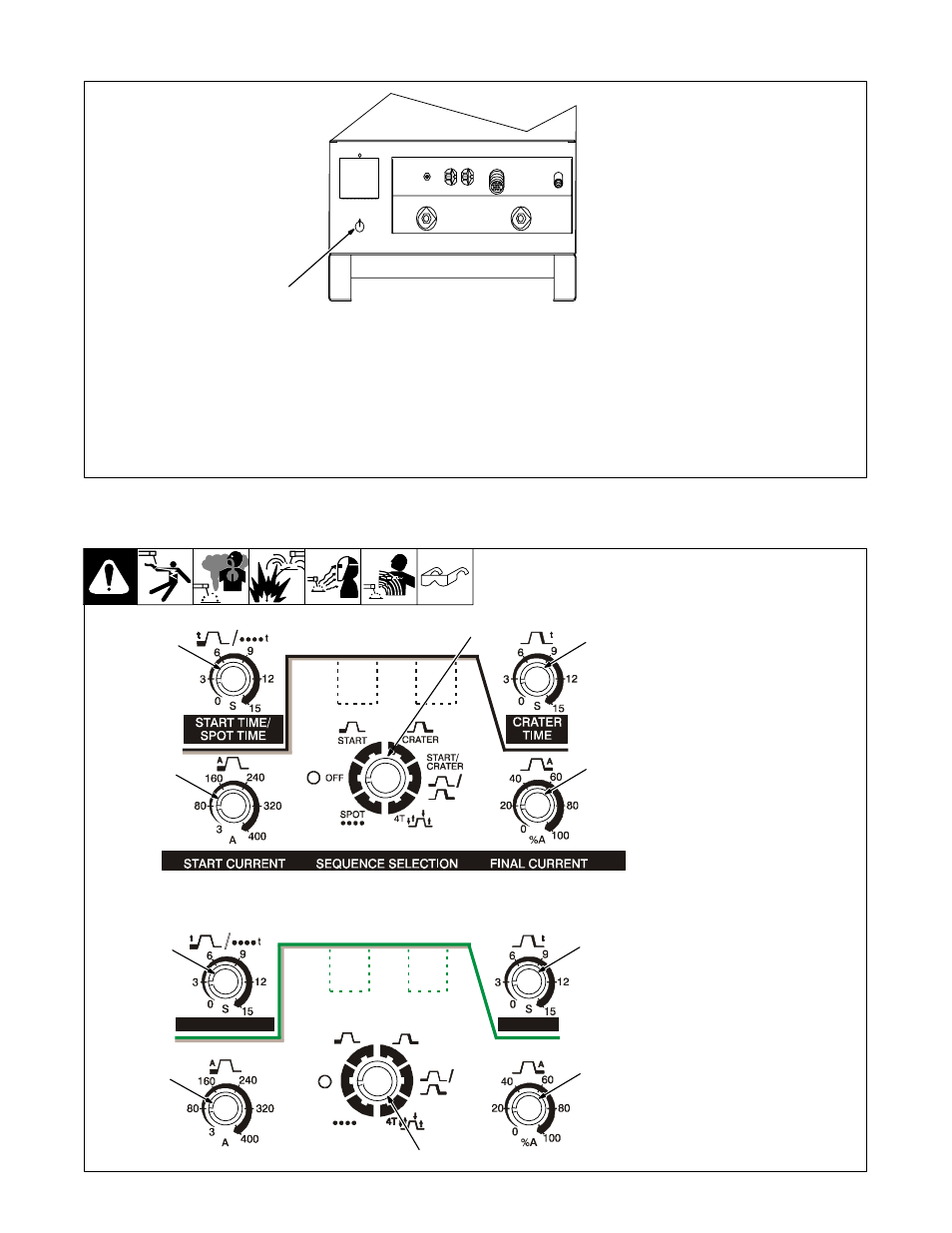

4-14. Optional Sequence Controls

1

Sequence Selection Switch

See Section 4-15.

2

Start Time/Spot Time Control

See Section 4-16.

3

Start Current Control

See Section 4-16.

4

Crater Time Control

See Section 4-17.

5

Final Current Control

See Section 4-17.

Ref. ST-191 372

4

2

1

3

5

4

2

1

3

5

(CE Nameplate Only)