Venting – Harman Stove Company PB 105 User Manual

Page 12

12

3-90-07205R19_05/13

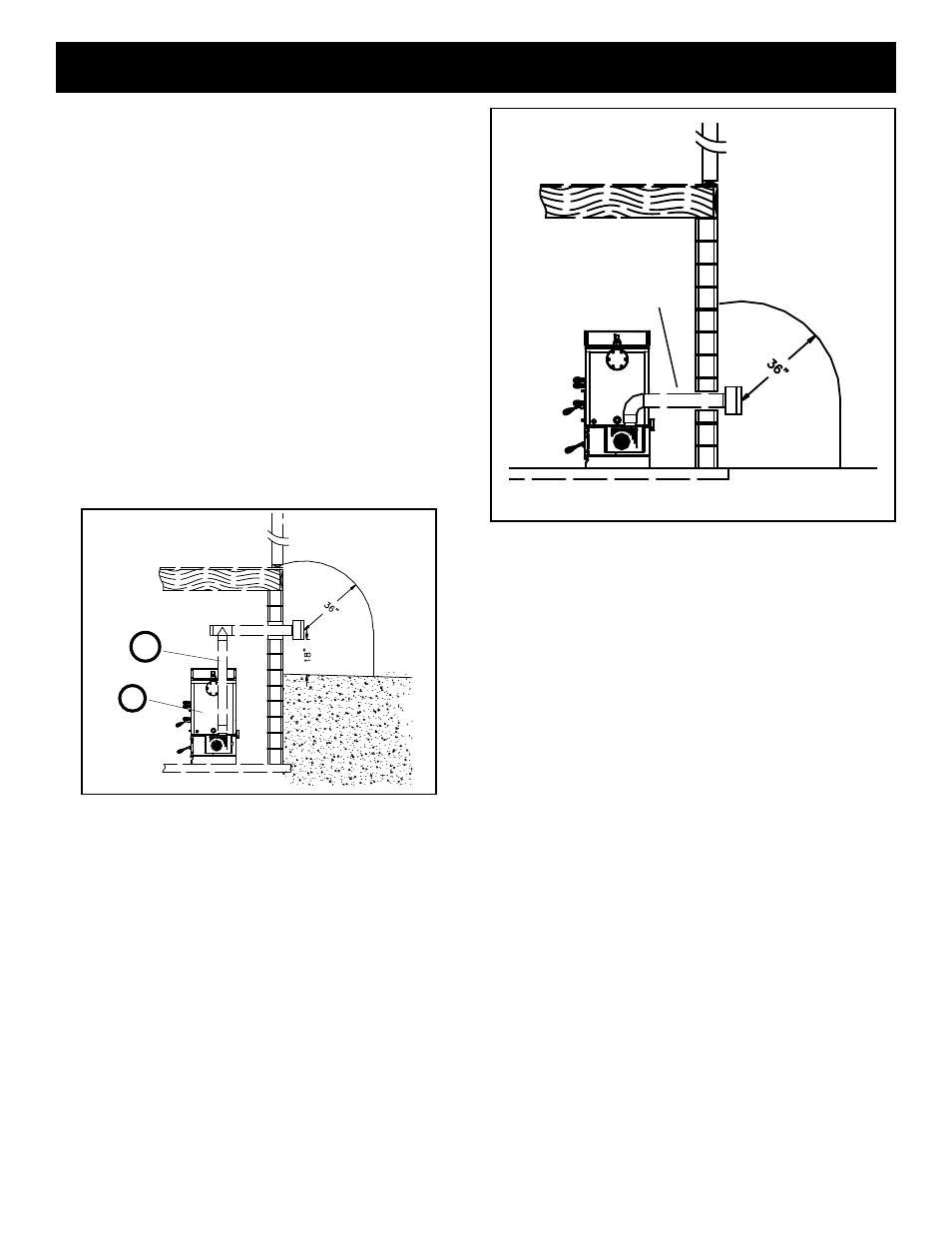

The minimum vent configuration is a 90

o

or Tee on a

starter collar and a 24” length horizontal through an

exterior wall. A cap on the end should direct the flue

gasses down and away from the structure. See Fig. 5.

The maximum horizontal length is 18 feet. The

minimum termination height above the exterior grade

is 18”. The maximum total length of any configuration

is 30 feet*.

* ( see venting graph on page 10 for exceptions )

NOTE: Cleanout Tee’s should always be used on the

transitions to horizontal pipe to allow easy access for

cleaning.

The venting graph allows for one(1) 90 deg. or Tee

fitting in any configuration.

If more 90’s, T’s, or 45’s are needed, the total length

must be adjusted to allow for the added restriction.

Up to four (4) additional 90’s, Tee’s, or equivalent 45’s

can be added as long as the overall length is adjusted

in accordance with the values listed below.

( See the venting graph on page 10.)

Each Vertical ---- 90 deg. or T subtract 2.5 feet

Each Vertical ---- 45 deg. subtract 1.5 feet

Each Horizontal - 90 deg. or T subtract 5.0 feet

Each Horizontal - 45 deg. subtract 2.5 feet

Any exterior venting (vent pipe exposed to outside

ambient temperatures) should be kept to a minimum,

due to potential condensation problems.

This is especially important in high humidity cold

weather climates, such as maritime areas, lake shores,

and low river valleys.

Venting

Venting

Use 4” pellet vent pipe only.

A combustion blower is used to extract the combustion

gases from the firebox. This creates a negative pressure in

the firebox and a positive pressure in the venting system

as shown in Fig. 4. The longer the vent pipe and more

elbows used in the system, the greater the flow resistance.

Because of these facts we recommend using as few elbows

as possible and 30 feet or less of vent pipe. The maximum

horizontal run should not exceed 18 feet.

Be sure to use wall and ceiling pass through fittings

(which are approved for pellet vent pipe ) when going

through combustible materials. Be sure to use a starting

collar to attach the venting system to the stove. The

starting collar must be sealed to the stove flue collar

with high temp silicone caulking or aluminum tape,

and screwed into the stove flue collar at least three

(3) places.

Fig. 4

-

+

Vent Pipe

4” pellet vent pipe (also known as “PL” vent) is

constructed of two layers with air space between the

layers. This air space acts as an insulator and reduces the

outside surface temperature to allow a minimum clearance

to combustibles as low as 1 inch. In Canada the minimum

clearance to combustibles is 3 inches.

The sections of pipe lock together to form an air tight seal

in most cases; however, in some cases a perfect seal is

not achieved. For this reason and the fact that the boiler

operates with a positive vent pressure, we specify that

all joints within the structure should also be sealed

with silicone.

NOTE:Use only 4” diameter approved PELLET

venting system. Be sure to inspect and clean exhaust

venting system frequently.

4” Type “L” or

“PL” Vent pipe

This is the minimum venting configuration. Fig. 5