Configuration, Warning – Honeywell Local Operator Interface S7999B User Manual

Page 20

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

65-0303—05

20

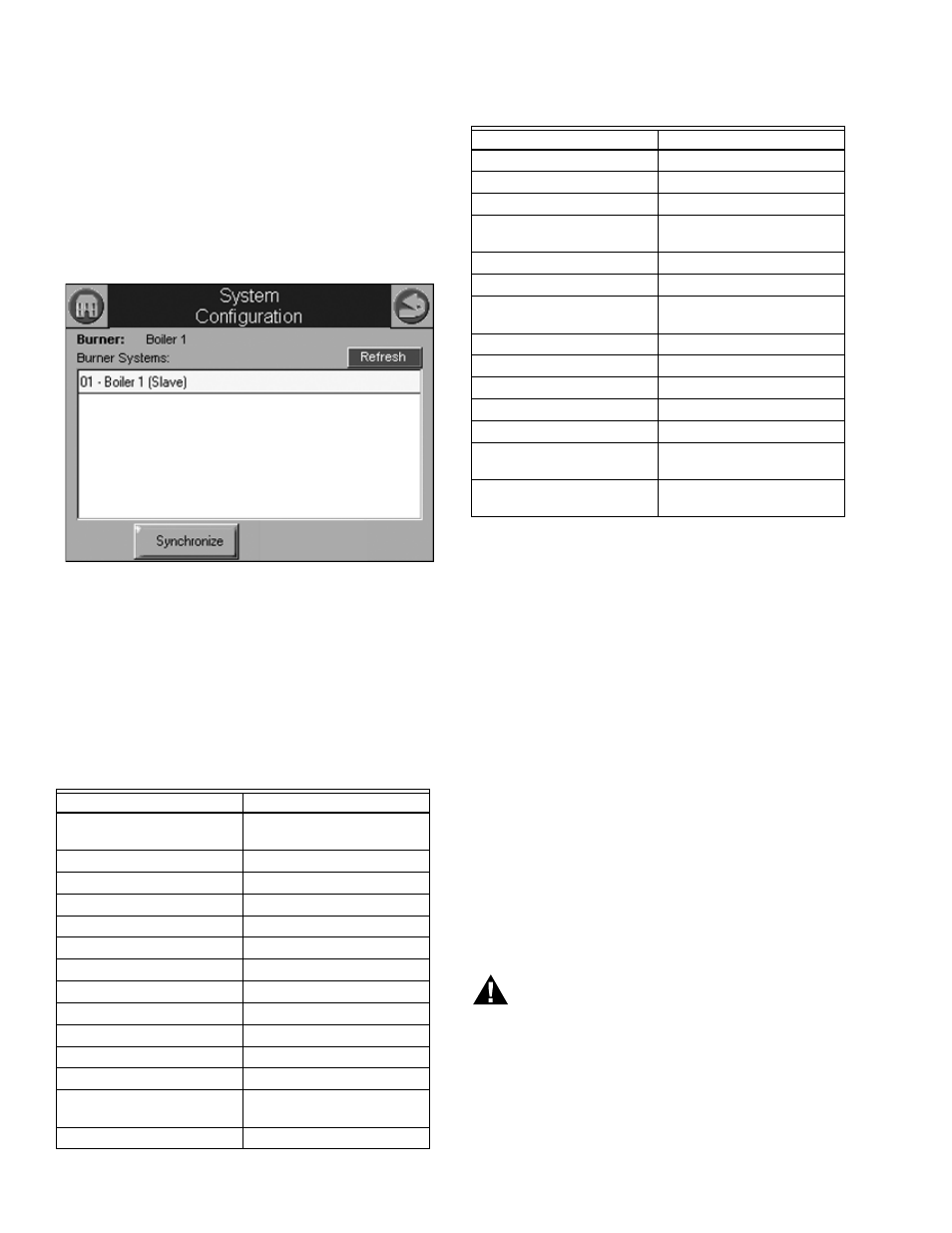

A new control is visible when configuration and status data is

gathered from it. This collection procedure takes a few

minutes. The control is marked as “Unknown” when no

configuration information exists. Normally, control configuration

data collection only needs to be performed when the control is

initially installed. However, a re synchronization is necessary

after the OI Display is reset. See Fig. 36.

The user presses the Synchronize button to begin

synchronization with the control. See Fig. 36.

Fig. 36. System synchronization.

Status of the synchronization is reflected in the dialog box. The

synchronization can be aborted by selecting the Cancel button.

Configuration

The SOLA Control can be configured from the OI Display. The

control configuration is grouped into the functional groups seen

in Table 5.

Most of this configuration is performed by either the contractor/

installer or at Honeywell. Each functional group is displayed on

the Configuration menu page.

Parameters in functional groups that are not applicable for the

installation can be ignored. In some cases, features in a

functional group are disabled by default and are enabled when

needed for the installation.

R7910A HYDRONIC CONTROL,

R7911 STEAM CONTROL

CONFIGURATION

PARAMETERS

The following pages list the configuration parameters available

for the R7910A or R7911 installed.

NOTE: Individual Configuration pages may differ from this

text as features are added or amended by Honeywell.

A password is required to make changes to the Configuration

Parameters. The SOLA Control will be in a Lockout 2 “waiting

for safety data verification” as received or will go to a Lockout 2

when changes are made to the safety data.

WARNING

Explosion Hazard.

Improper configuration can cause fuel buildup and

explosion.

Improper user operation may result in PROPERTY

LOSS, PHYSICAL INJURY or DEATH.

The OI Display used to change parameters, must be

attempted by only experienced and/or licensed

burner/boiler operators and mechanics.

Table 5. Functional Configuration Groups.

Hydronic Control

Steam Control

System Identification and

Access

Steam Identification and

Access

CH - Central Heat

Steam Configuration

Outdoor Reset

Modulation Configuration

DHW - Domestic Hot Water

Pump Configuration

DHW Storage

DHW Plate

Warm Weather Shutdown

Demand Priority

Modulation Configuration

Statistics Configuration

Pump Configuration

Stack Limit

Statistics Configuration

Annunciation Configuration

High Limit

Burner Control Interlocks

Stack Limit

Burner control Timings and

Rates

Delta T Limits

T-Rise Limit

Heat Exchanger High Limit

Anti-condensation

Burner Control Flame Failure

Frost Protection

Configuration

System Configuration

Annunciation Configuration

Fan Configuration

Burner Control Interlocks

Lead Lag Configuration

Burner Control Timings and

Rates

Burner Control Ignition

Burner Control Flame Failure

System Configuration

Fan Configuration

Sensor Configuration

Lead Lag Slave

Configuration

Lead Lag Master

Configuration

Table 5. Functional Configuration Groups.

Hydronic Control

Steam Control