Portable Winch Gas-powered pulling/lifting winch PCH1000 User Manual

Page 11

11

Double braid ropes consist of a cover or jacket braided over a separately braided core. The

strength of the double braid rope is shared between the cover and the core. Damage to the

cover also usually affects the core and ultimately the strength of the rope.

Rope inspection is done by running both hands over the entire length of the rope while turning it

in order to see all around. It is a visual as well as a touch feeling process.

TWIST:

Every time you set the rope over the capstan drum you are twisting the rope. Depending on the

length of the rope, and what percentage of the rope you use, you will sooner or later have a

twisted rope with reduced capacity because the strands are not loaded evenly. You can un-twist

the rope by spinning the rope to a free end.

It is a good practice to reverse the rope

– use both ends. In addition to help with the twist

problem, the rope will also wear more evenly.

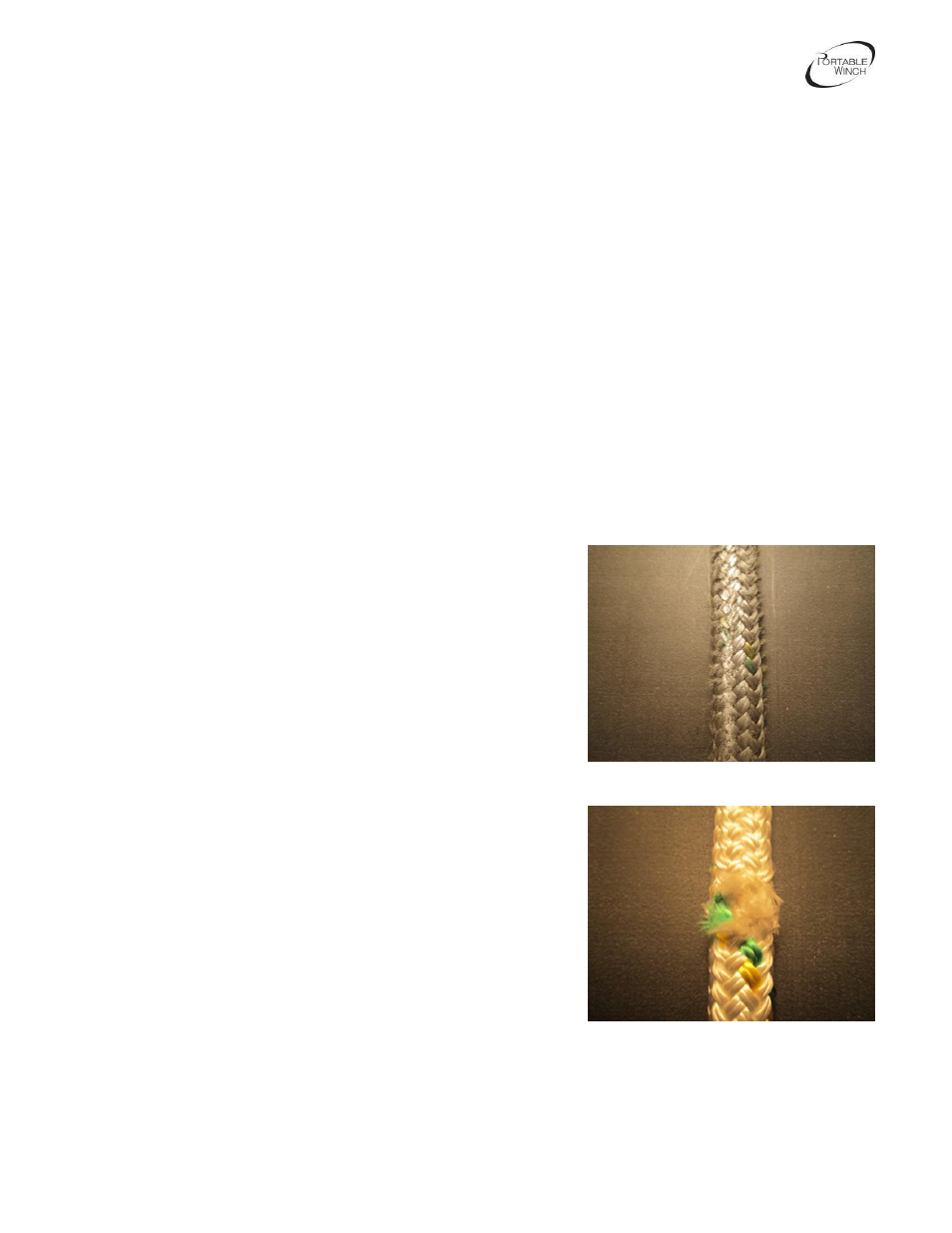

GREY COLOR:

This comes from aluminium residues from the friction on the

capstan drum. Your hands will get dirty but this does not

damage the rope.

CUT STRANDS:

A strand is made of one, two or more groups of twisted

yarn. Braided ropes are typically 16-, 24- or 32-strand. They

can get cut by abrasion against sharp edges or surfaces, or

by cyclic tension wear.

If three or more adjacent strands are cut, the rope shall be

retired.