Bryant 542E User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

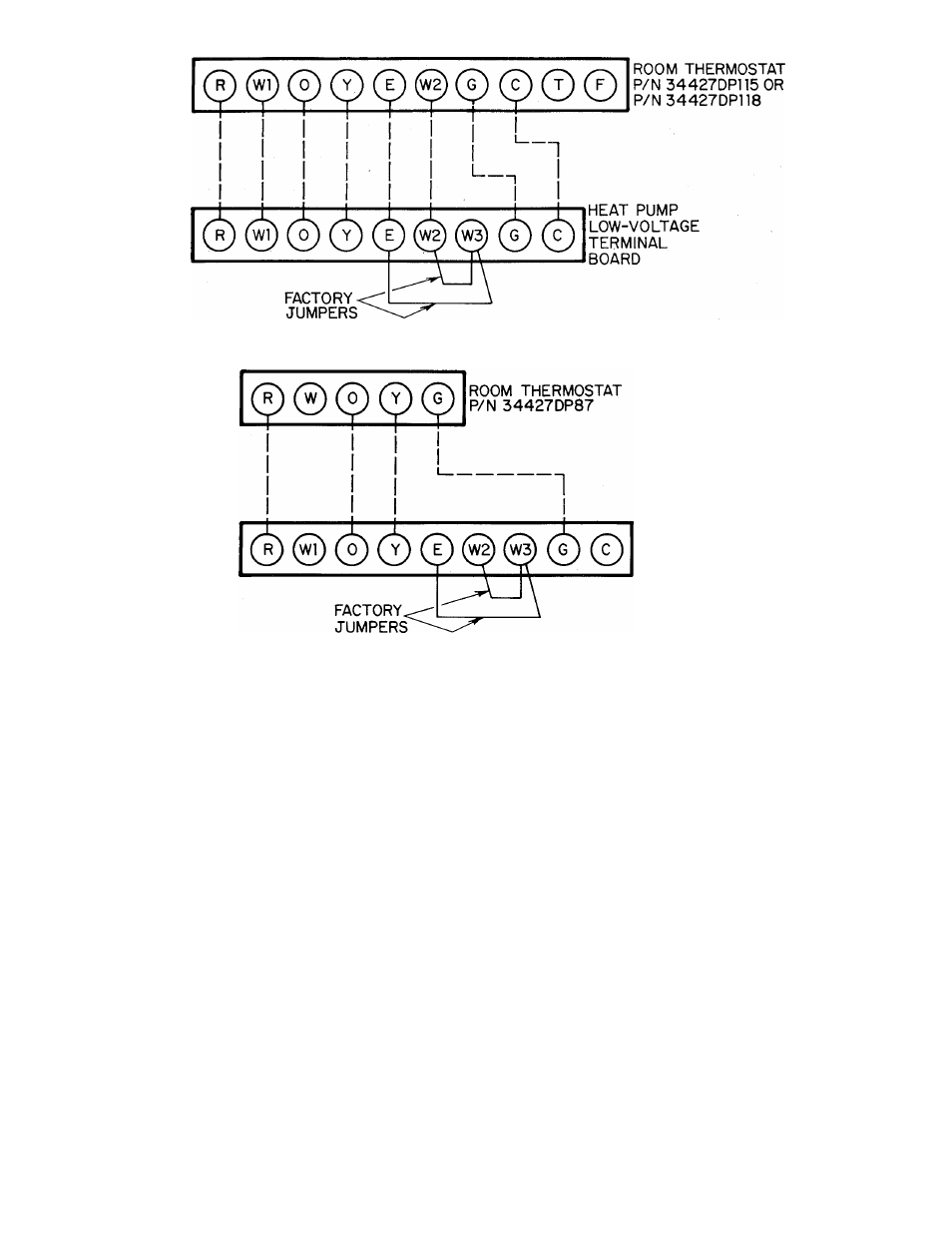

Figure 14—Field Low-Voltage Connections Using Room

Thermostat P/N 34427DP115or P/N 34427DP118

HEAT PUMP

LOW-VOLTAGE

TERMINAL

BOARD

Figure 15—Field Low-Voltage Connections Using Room Thermostat P/N 34427DP87

Mount the room thermostat on an inside wall in the space to

be conditioned. The thermostat should be approximately 4 or

5 feet above the floor and located where it will not be sub

jected to either a cooling or heating source, or direct ex

posure to sunlight.

Use No. 18 AWG “color-coded” insulated wires to make the

low-voltage connections between the thermostat and the

unit. If the thermostat is located more than 100 feet from

the unit as measured along the low-voltage wires, use No. 16

AWG wire.

A grommeted low-voltage inlet hole has been provided in the

control panel adjacent to the control access panel. See

Figure 3 or 4. Run the low-voltage thermostat leads thru the

inlet hole and to the low-voltage terminal board. See Figure

12. Complete the low-voltage thermostat connections as

shown in Figure 14 or 15, depending on which recommended

room thermostat is being used.

C. Heat Anticipator Settings

The recommended room thermostats have a fixed heat antic

ipator for heat pump heating. When using an accessory

electric heater to provide supplemental heat and emergency

heat capability for the system, see the Installation Instruc

tions packaged with the heater for setting the adjustable

second-stage heat anticipator.

V. PREPARING UNIT FOR STARTUP

WARNING/DANGER:

A failure to Inllow the-e in.struclion.'

could roiult in seiiou.-< person;.I injury:

1. Follow recognized safety practice.- and wear protective

goggles when checking or .servicing the refrigerant

2. Do not oper.ali' the compres.=or or pro\ ide any electric

power to thi- unil unles.s compre-.'or tormin.il co\ or i.- in

place and secured.

0. Do not rerno\e the compres.-or terminal cu\er iinli! all

electrical source- lia\e been di.sronnected.

1. If a rcl'ngeranl leak is su.-pi'Cted ,iround the com)!re.--or

terminals, relie\e all pres-utv from the -v-tem before

touching or di-ttirliing anything inside the tciminal

■7). .Sy-tem contani.- ml :ind refri.ger.int under pre.-.-tire. De

not use a torch to remove any component To remote a

component, wear protective goggles and [U'oceed as fol-

a. Shut oil electrical power to unit.

li. Reliete all pressure from sy-tem.

c. (7ut component connectin.g tubing with tubing ciit-

ti'i- and remove component from unit.

d. When nece.ssary. un.-weat remaining tubing -tubs

carefully. Oil may ignite when exposed to torch

ÎiisilïiïiSilSijîliSîiiïiiliillS^^

Proceed as follows to prepare the unit for initial startup:

1. Read and follow instructions on all WARNING, CAU

TION, and INFORMATION labels attached to the unit;

for example, blower rotation labels etc.

2. Visually inspect for oil at all refrigerant tubing connec

tions and on unit base. Detecting oil generally indicates

a refrigerant leak. Leak-test all refrigerant tubing con

nections, using electronic leak detector, halide torch, or

liquid-soap solution. If refrigerant leak is detected, see

Section VI, “Refrigerant Leaks,” in these instructions.

-

7

-