Iii. duct connections – Bryant 542E User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

TABLE ll-ELECTRICAL DATA-MODEL 542E-SIZES 024 THRU 042

MODEL

542E

SIZE

024

030

036

042

SERIES

A

A

A

A

Unit Volts-Phase (60Hz)

208-230-1

208-230-1

208-230-1

208/230-3

230-1

208/230-3

Operating Voltage Range

197-253

197-253

197-253

187-253

207-253

187-253

Total Unit Amps

16.7

22.7

23.9

14.8

28.7

21.0

Max Branch Circuit Fuse Size (Amps)

30

45

45

25

50

40

Unit Ampacity for Wire Sizing

20.2

27.5

29.2

17.8

34.9

25.2

Minimum Wire Size (AWG)*

10

10

10

12

8

10

Maximum Wire Length (Ft)*

115

85

80

95

112

107

TABLE MI-ELECTRICAL DATA-MODELS 542E048, 542D060, & 542E060

MODEL

542E

542E

542D & 542E

SIZE

048

060

060

SERIES

A

A

A

Unit Volts—Phase (60Flz)

230-1

208/230-3

460-3

230-1

208/230-3

460-3

Operating Voltage Range

207-253

187-253

414-506

207-253

187-253

414-506

Total Unit Amps

31.9

22.4

10.9

40.9

26.1

13.7

Max Branch Circuit Fuse Size (Amps)

60

45

20

60

50

25

Unit Ampacity for Wire Sizing

38.9

27.1

13.2

49.8

31.3

16.4

Minimum Wire Size (AWG)*

8

10

14

6

8

12

Maximum Wire Length (Ft)*

101

100

181

123

137

229

*Only use copper wire for field connections to unit. Wire size is based on 60 or 75°C copper conductor at 86°F (30°C) ambient tempera

ture and ampacity shown in fable. If other than 60 or 75°C copper conductor is used, if ambient temperature is above 86°F, or if voltage

drop of wire exceeds 2% of unit rated voltage, determine wire size from ampacity shown and the National Electrical Code. Wire lengths

shown are measured one way along the wire path between unit and service panel for minimum voltage drop.

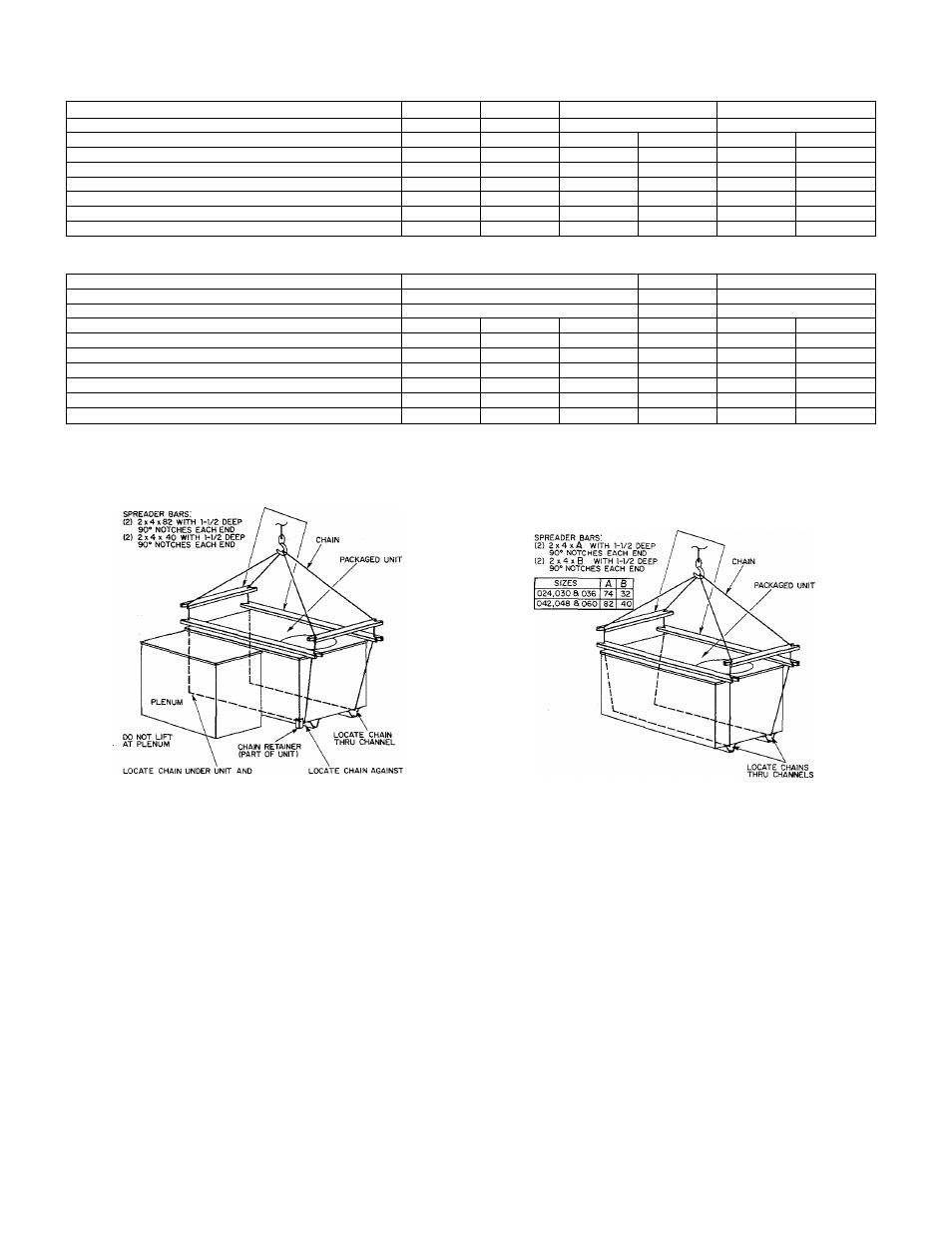

USE SPREADER BARS TO PROTECT UNIT

USE SPREADER BARS TO PROTECT UNIT

ONE INCH FROM PLENUM FOR

PROPER FIT ON CURB AND PLATFORM

CHAIN RETAINER FOR

PROPER BALANCE

Figure 7—542D060 Suggested Rigging

Prime the trap with water and check the condensate line for

leaks.

CAUTION;

Do not undersize the condensate drain line.

During the heating defrost cycle, defrost water from the

melting ice on the outdoor coil flows through the slots in the

heat pump base directly below the outdoor coil. If a field-sup-

plied drain pan is to be used to catch the defrost water, this

pan should be at least 2 inches high and extend at least 2 in

ches beyond the width and length of the unit.

If the installation requires draining the condensate and/or

defrost away from the unit, connect a minimum of 7/8-inch

OD copper tubing, 3/4-inch galvanized pipe, or 7/8-inch

plastic pipe. The drainage lines should pitch downward at a

slope of at least 1 inch in every 10 feet of horizontal run.

Both condensate and defrost water can be drained directly

onto the roof in rooftop installations where permitted or

onto a gravel apron in ground-level installations. When a

gravel apron is being used, it should extend at least 24 in

ches around the mounting pad to ensure proper drainage.

III. DUCT CONNECTIONS

Flanges are provided on the 542E supply- and return-air

A79148

Figure 8—542E Suggested Rigging

openings on the side of the unit. See Figure 3 for connection

sizes and locations. See Figures 10 and 11 for illustrations of

typical installations.

Flanges are provided on the 542D supply- and return-air

openings on the bottom of the unit. See Figure 4 for connec

tion sizes and locations.

NOTE:

The minimum installation requirements of the duct

system must be in accordance with the standards of the Na

tional Fire Protection Association for installation of air con

ditioning and ventilating systems of other than residence

type, NFPA No. 90; or residence type, NFPA No. 90B; and/or

local codes and ordinances.

CAUTION:

When the duct system fastening holes are being

drilled into the 542E side instead of the unit duct flanges

provided, use care to avoid puncturing the coil tubes.

The following criteria must be followed when selecting, siz

ing, and installing ductwork:

1. When electric heater is installed, a minimum clearance

of one inch to combustible materials must be main

tained for the first 36 inches of duct.

2. It is recommended that flexible connectors be used be-

-

4

-