Operations – AccuTemp EVOLUTION GAS STEAMER User Manual

Page 25

MP4010-1003

EVOLUTION GAS STEAMER

19

Preparing the Evolution Connection-Less model for use each day requires very little

time and effort. Simply verify that the steamer is clean, the drain valve is in the

closed position and the cooking chamber is filled with approximately 2½ Gallons of

tap water. Close the door and push the ON/Off key on the keypad. The water level

will need to be monitored and filled as required. Do not use the low water warning

lamp as the indicator to check the water level as this can damage the steamer over

time.

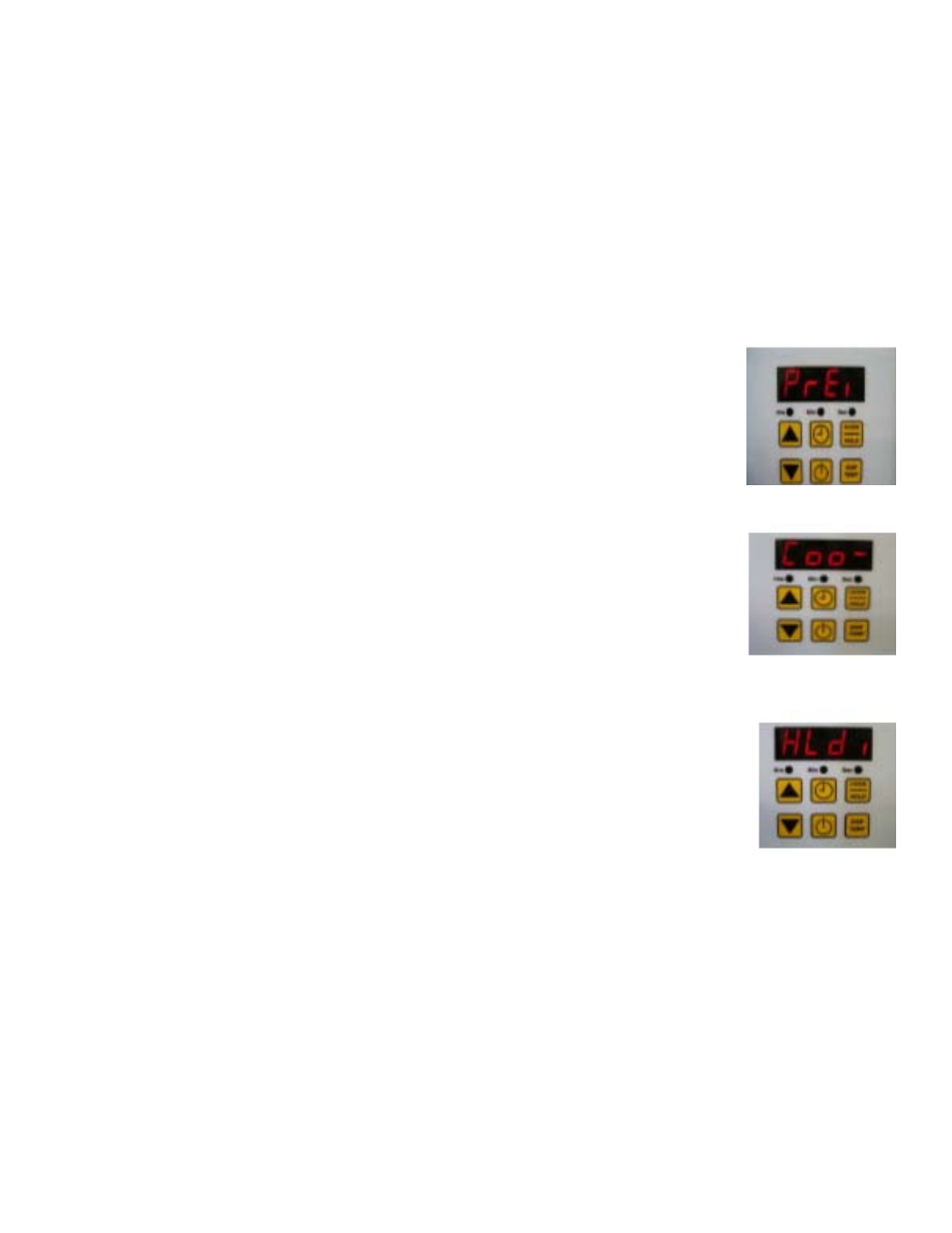

PREhEATING ( Fig. 16)

1) Depress the On/Off Key to turn on the steamer. The display will indicate PrE.

2) Once the steamer is preheated and ready to cook, the display will indicate

COO (Cook Mode) or hLd (hold Mode).

3) Depress the DISP TEMP button to display the current cooking chamber

temperature.

COOKING ( Fig. 17)

1) Depress the COOK/hOLD button to select the Cook Mode (COO).

2) Open the door and place food into the cooking chamber. Shut the door.

Cooking begins immediately.

3) Timer — Depress the TIMER button and depress the ARROW keys [▲ or ▼]

until the desired time is displayed. The timer starts automatically. At the end of

the timed cycle, a beeper will sound.

4) Depress the DISP TEMP button to display the current cooking chamber

temperature.

hOLDING (Fig. 18)

In “hold” the steamer temperature is set for 180°F from the factory. The hold

temperature can be changed to a single value for temperatures ranging from150°

F to 190° F if required. Contact the AccuTemp Technical Service Department

for assistance at 800.480.0415 or 260.469.3040. hold can also be used during

downtimes to save energy and water while keeping the steamer preheated.

1) Depress the COOK/hOLD button to select the hold Mode (hLd).

2) Open the door and place food into the cooking chamber. Shut the door.

3) Food will be held at the preset holding temperature. The factory default setting is

set at 180° F.

4)Depress the DISP TEMP button to display the current cooking chamber

temperature.

DAILY PREPARATION FOR USE - CONNECTIONLESS MODEL

OPERATIONS

Fig. 18

Fig. 16

Fig. 17