Installation, Install water piping – Fulton Pulse HW (PHW) Fully Condensing Hydronic Boiler User Manual

Page 15

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

SECTION 2

PHW-IOM-2013-0214

INSTALLATION

2-9

A positive system pressure at the highest point of 5 to

10 psi.

Make up water valve should be designed to add water

to the system at the outlet of the boiler and should

not be fed directly into the boiler.

2. Air removal equipment, including air separator and

automatic air breather valves.

3. A functioning expansion tank designed to system

specifi cations.

4. Filtration to remove particulates installed inline with the

suction side of the recirculating pump.

5. Bypass chemical feeder for corrosion inhibitor

maintenance.

6. Optionally a water meter could be installed in series

with the automatic pressure activated water make up

valve to monitor any make up water.

7. Ensure water quality meets the following:

Oxygen - less than 250 ppb (operating condition)

pH - must be in the range of 8-10

Total Iron & Copper - less than 25 ppm

Corrosion Inhibitor - level capable of maintaining

iron corrosion rates < 2 mpy. Due to changing

environmental restrictions, a non-heavy metal, all

organic inhibitor is recommended, which is designed

for multi-metal systems including ferrous metals and

yellow metals such as copper and brass.

Chlorides - less than 250 ppm as Cl. Limit applicable

only to installations utilizing duplex steel pressure

vessel components.

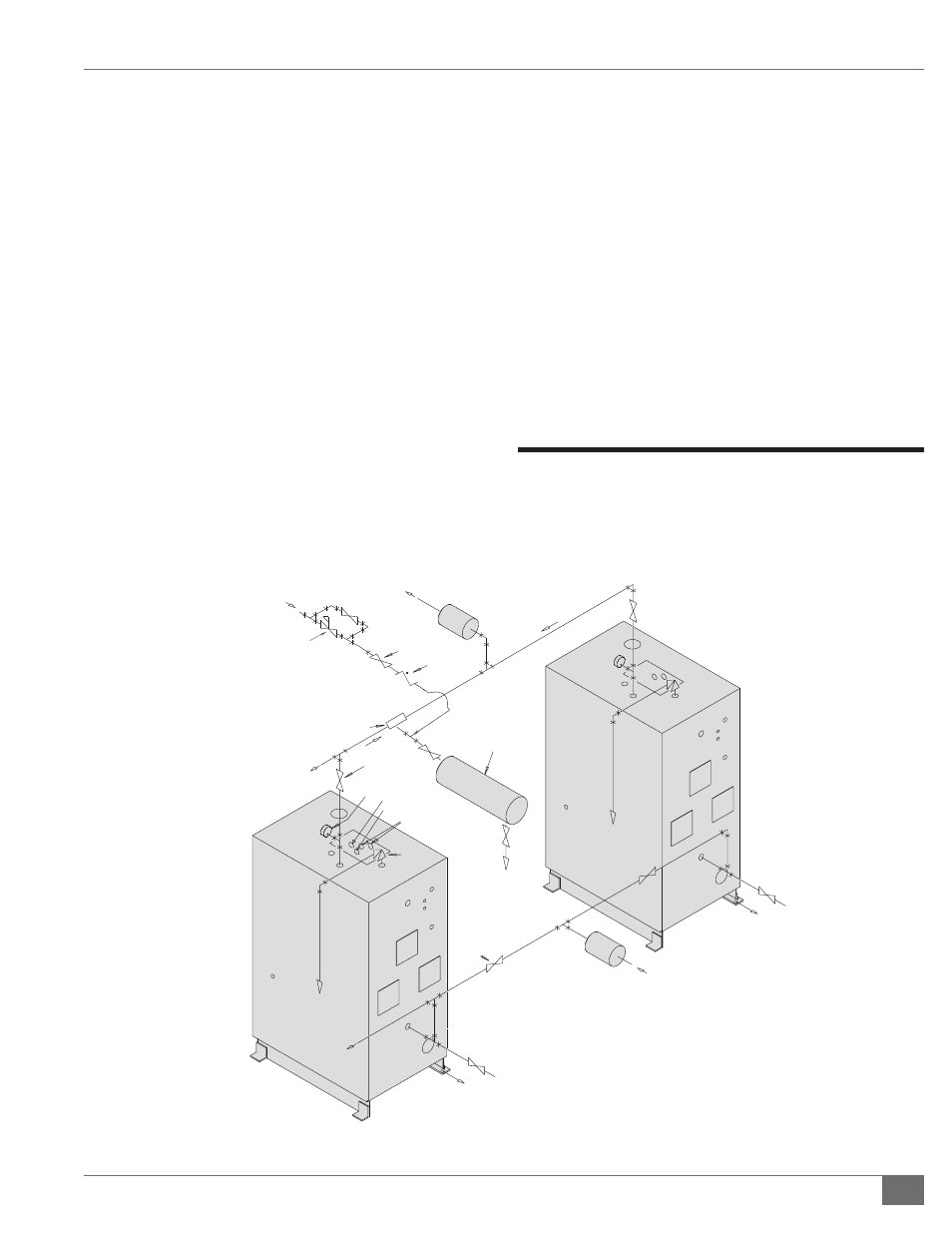

Install Water Piping

The bottom connection to the boiler is the INLET and must be

connected as the return from the system. The top connection

on the boiler is the OUTLET and must be connected as the

supply to the system.

ADDITONAL

BOILER (S)

HEATING

SUPPLY

MANIFOLD

ADDITIONAL

BOILER (S)

HOT WATER

STOP VALVE

TEMPERATURE

PRESSURE

GAUGE

OPERATING AND

HIGH LIMIT AQUASTATS

(INTERNAL)

ASME

SAFETY

VALVE

STOP

VALVE

DRAIN

CONDENSATE

DRAIN

Multiple Boiler Installation

TYPICAL PIPING SYSTEM

UNLESS OTHERWISE NOTED, ALL

COMPONENTS SHOWN ARE TYPICAL

ON EACH BOILER

HEATING

RETURN

MANIFOLD

EXPANSION

TANK

STOP

VALVE

CHECK

VALVE

PRESSURE

REDUCING

VALVE

MAKEUP

WATER

AUTOMATIC

AIR VENT

FLAME ROD

SPARK PLUG

FIGURE 6 - TYPICAL PIPING (MULTIPLE BOILER SYSTEM)